Countercurrent Liquefied Gas Evaporation and Condensation Plant with Breaker Plates

A technology for breaking plates and equipment, which is applied in the fields of desalination/purification, evaporation/condensation units, and can solve problems such as heavy metal pressure vessels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

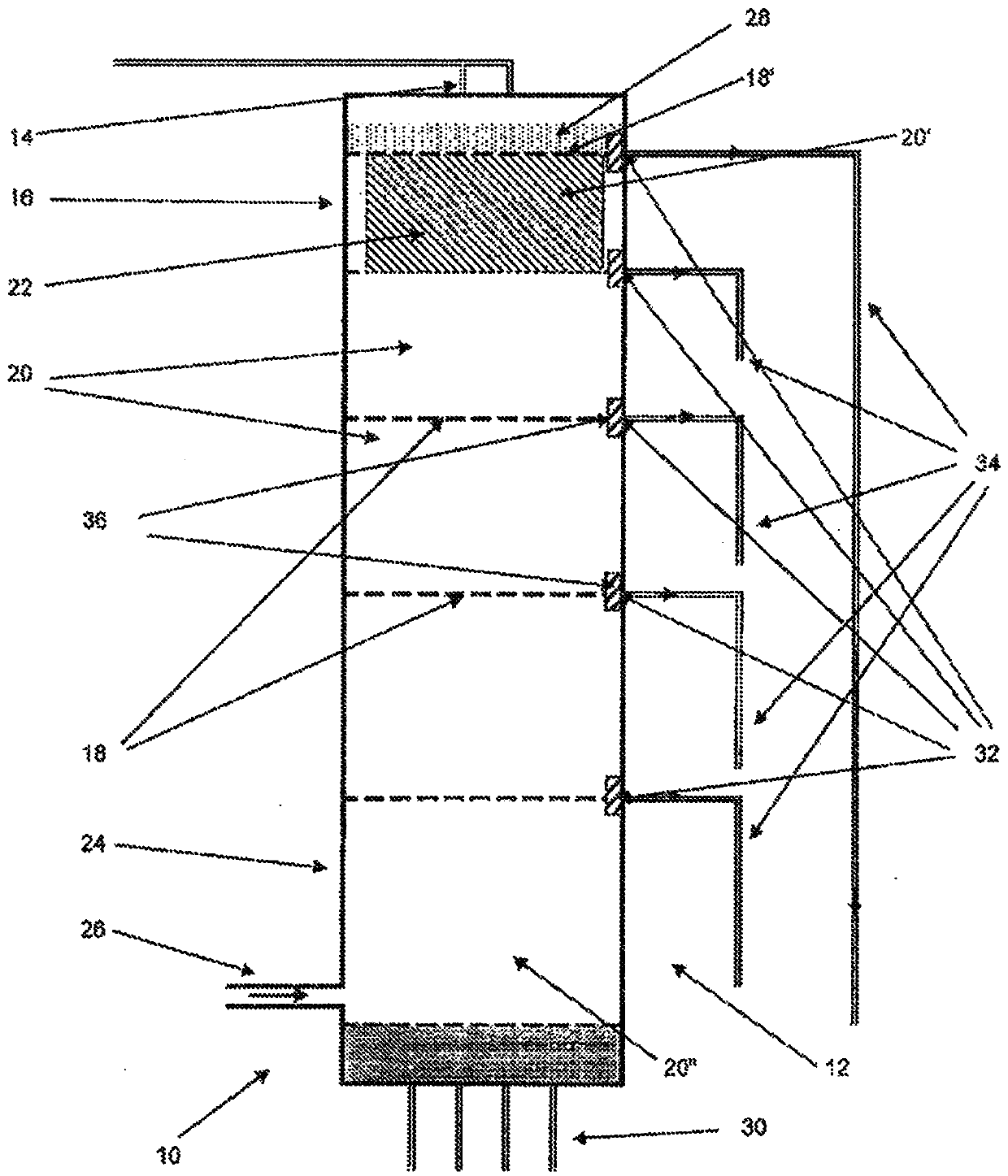

[0150] like Figure 5 The configuration shown has an evaporation unit and a condensation unit with a height of 12 meters and a diameter of 75 cm for desalination of brine. The evaporation unit and condensation unit consist of five evaporation / condensation zones. Seawater input temperature and evaporation area temperature are as follows:

[0151] Input hot salt water 85℃

[0152]Zone 1 (uppermost) 76°C

[0153] Section 2 70°C

[0154] Section 3 64°C

[0155] Section 4 57°C

[0156] Section 5 (bottom) 52°C

[0157] Results obtained from operating the above unit under these conditions demonstrate that a distilled water output in excess of 18,000 liters per 24 hours can be achieved. The water quality was measured using a standard conductivity meter and the total dissolved solids level was found to be less than 20 ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com