Polyacrylonitrile (pan) polymers with low polydispersity index (pdi) and carbon fibers made therefrom

A polyacrylonitrile, polymer technology, applied in the chemical characteristics of fibers, household appliances, other household appliances, etc., can solve problems such as difficulties in the development of mechanical properties of fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] Synthesis of PAN polymer

[0094] PAN polymers were prepared according to the formulations for PAN polymerization shown in Tables 1A-1C.

[0095] Table 1A - Formulations used for PAN polymerization

[0096] components Preparation 1 Preparation 2 Preparation 3 Preparation 4 Acrylonitrile (AN) 99.30 99.30 99.30 99.30 Itaconic acid (ITA) 0.70 0.70 0.70 0.70 CPBZ 0.113% 0.029% BDSTD 0.359%* 0.045%

[0097] Table 1B - Formulations used for PAN polymerization

[0098]

[0099]

[0100] Table 1C - Formulations for PAN polymerization

[0101]

[0102] In the above table, CPDTC, CPBZ, and BDSTD are RAFT agents, among which:

[0103] CPDTC = 2-cyano-2-propyl dodecyl trithiocarbonate

[0104] CPBZ = 2-cyano-2-propylbenzodithioate

[0105] BDSTD = bis-dodecylsulfanylthiocarbonyl disulfide

[0106] Note: *Raft agent is used in mole %, based on total monomer.

[0107] Controlled / living radical PAN polymeriz...

Embodiment 2

[0125] Manufacture of white fibers

[0126] Carbon fiber precursors (or white fibers) were formed by wet spinning using PAN polymer made from Formulation 5 as described in Example 1 . White fibers were formed by an air gap spinning process using a PAN polymer made from Formulation 12 as described in Example 1 with a 150 μm spinneret.

[0127] The properties of the white fibers were determined as follows.

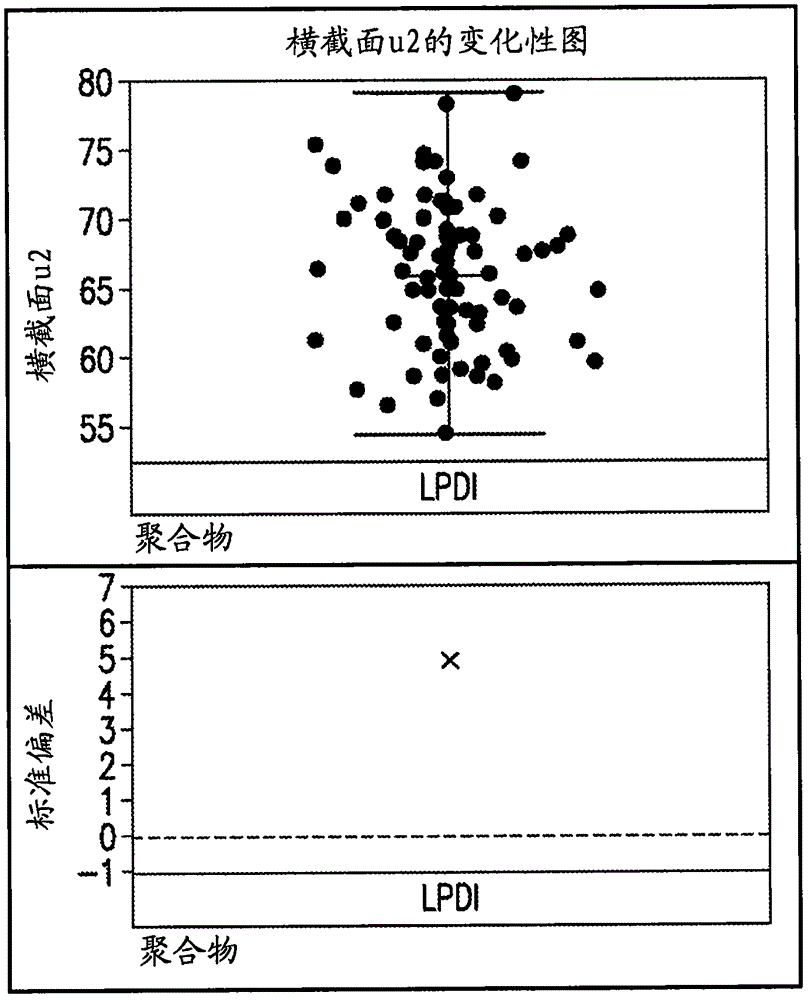

[0128] cross-sectional analysis

[0129] Samples of white fiber bundles were dipped in acrylic resin and cured. The cured fiber resin rods were sanded on a grounder using different grades of sander paper to obtain a smooth cross-section. Afterwards, the cross-sectional uniformity of the fiber cross-section was measured under an optical microscope with an image analysis system.

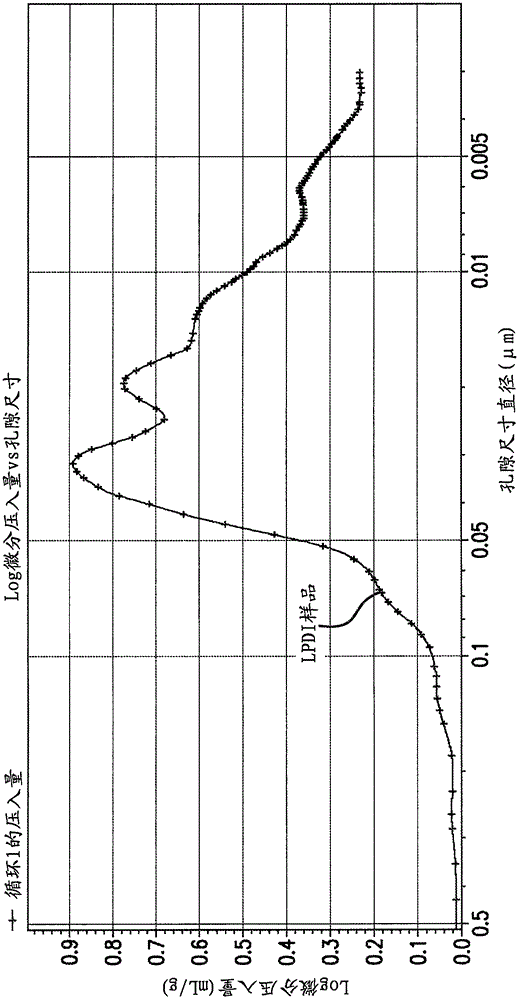

[0130] porosimetry

[0131] For air-gap spinning, fiber samples leaving the coagulation bath were freeze-dried at -60°C, and the freeze-dried samples were tested by mercury porosimetry for poros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com