Drive unit

A drive unit and drive shaft technology, applied in the direction of electrical components, electric components, transmissions, etc., can solve the problems of interference, axial support is no longer possible, etc., and achieve the effect of great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

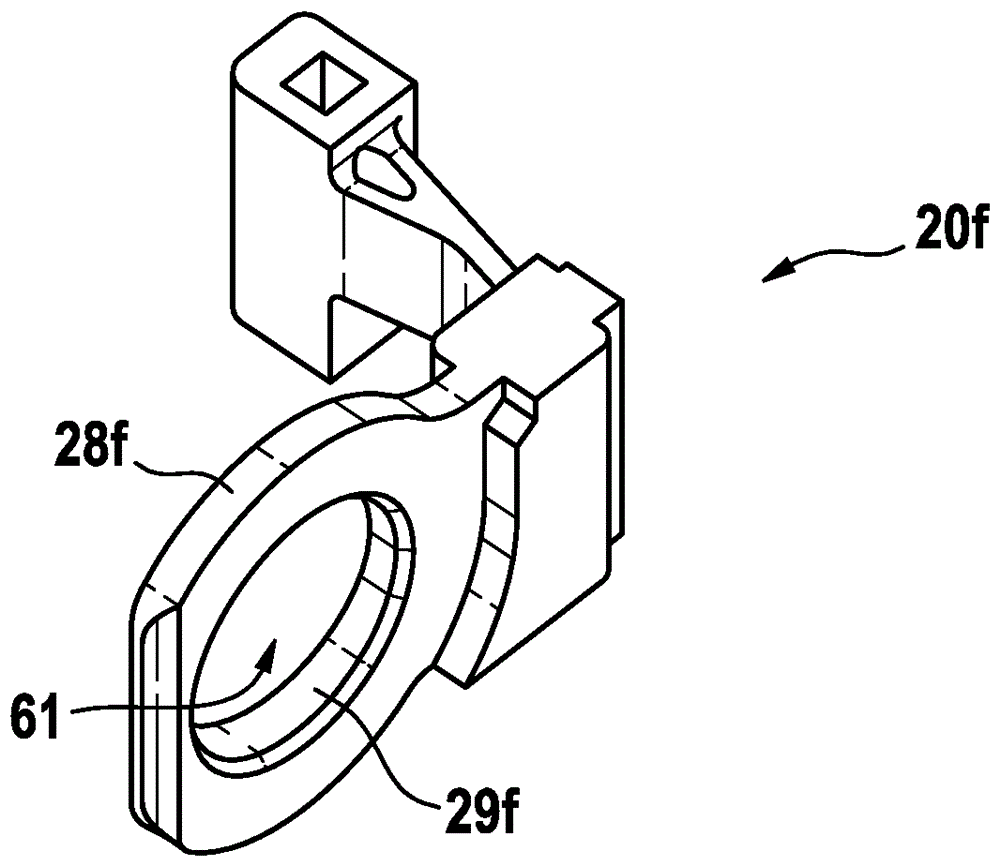

Image

Examples

Embodiment Construction

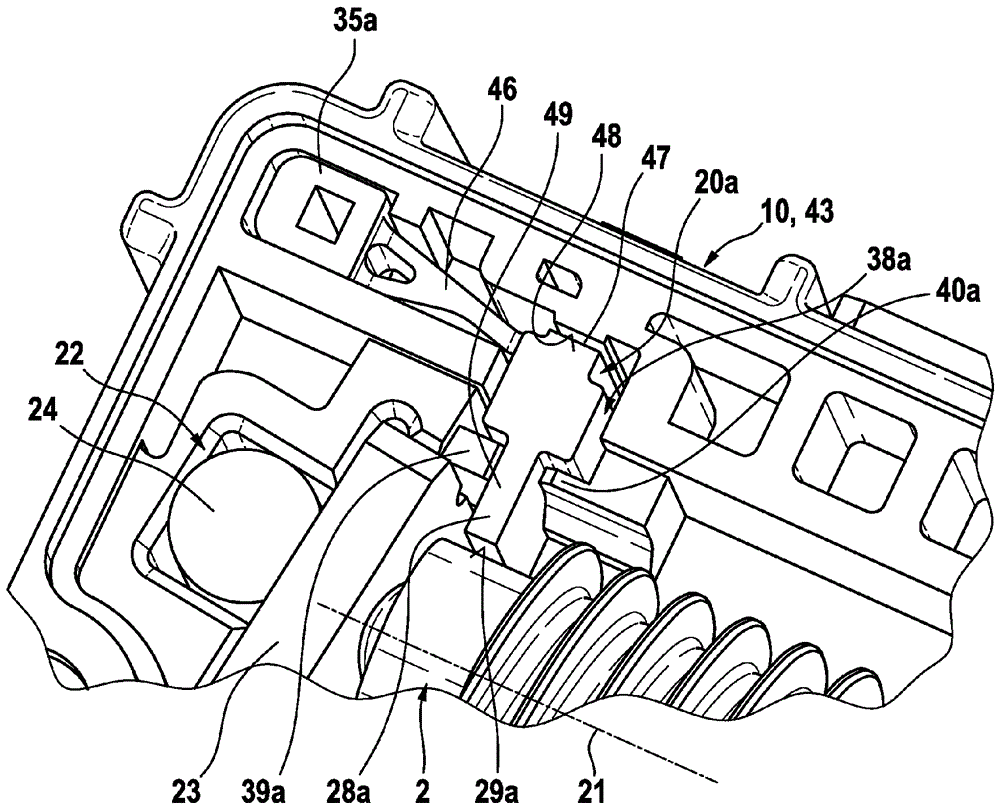

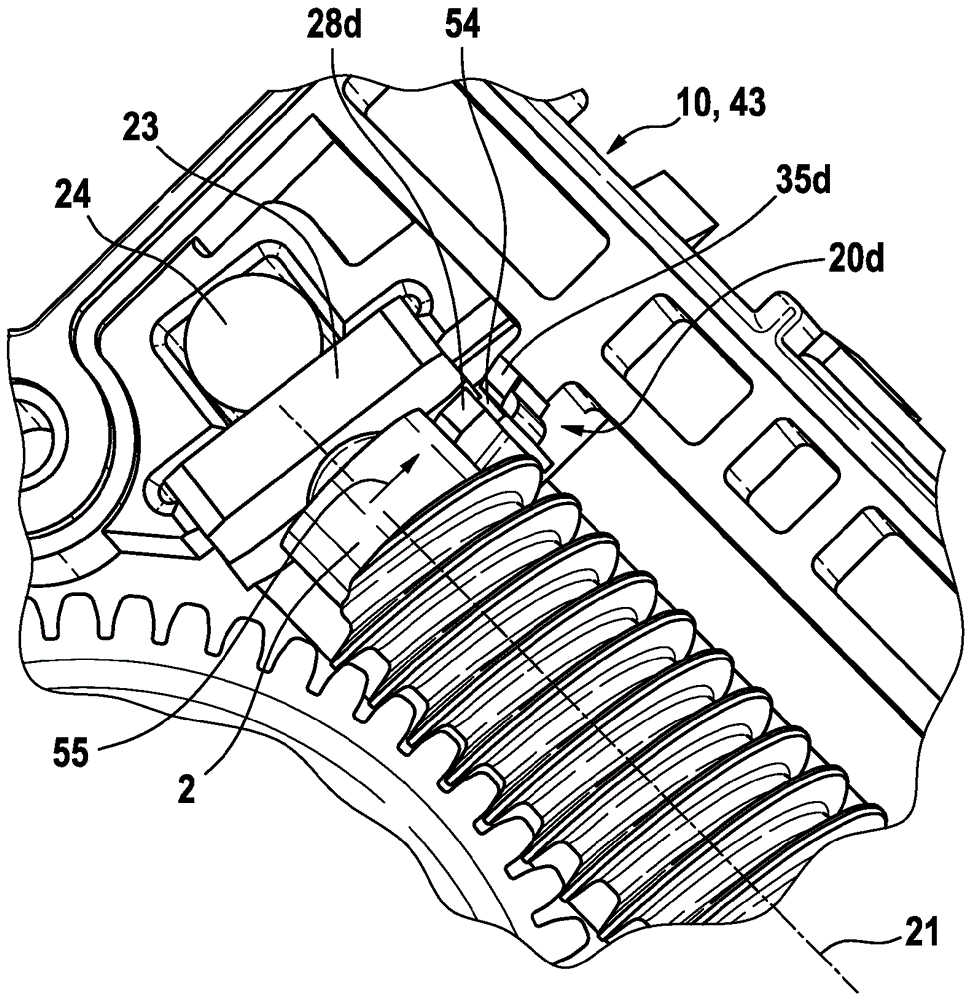

[0037] Identical elements or elements with the same function are provided with the same reference symbols in the figures.

[0038] exist figure 1 The basic structure of a drive unit 100 according to the invention, as it is used as a component of a convenience drive in a motor vehicle, is shown in a very simplified form. A convenience drive is to be understood within the scope of the present invention as an example and without limitation a window regulator drive, a sliding sunroof drive, a seat adjustment drive or the like.

[0039] The drive unit 100 has a drive motor 1 designed as an electric motor with a drive shaft 2 protruding from a housing of the drive motor 1 . The drive shaft 2 of the drive motor 1 is mounted on both sides of the drive motor 1 in first and second bearing elements 3 , 4 , which are preferably designed as ball bearings or slide bearings. exist figure 1 In the embodiment shown in, the two supporting elements 3, 4 are housed or arranged respectively in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com