Resistance-reducing agent used for reusable slippery water fracturing fluid and preparation method thereof

A drag-reducing agent and water fracturing technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems affecting fracturing fluid flowback, environmental pollution, and increased production costs, and achieve swelling and drag reduction Outstanding performance, avoiding the risk of environmental pollution, and reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

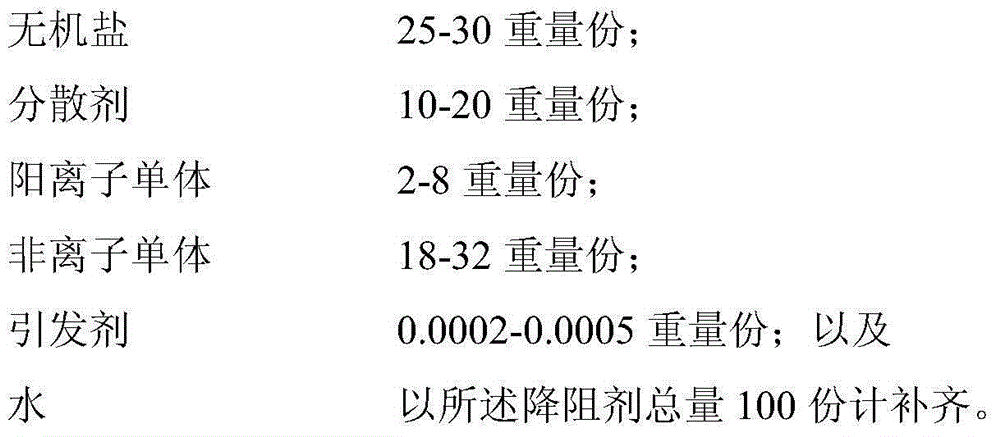

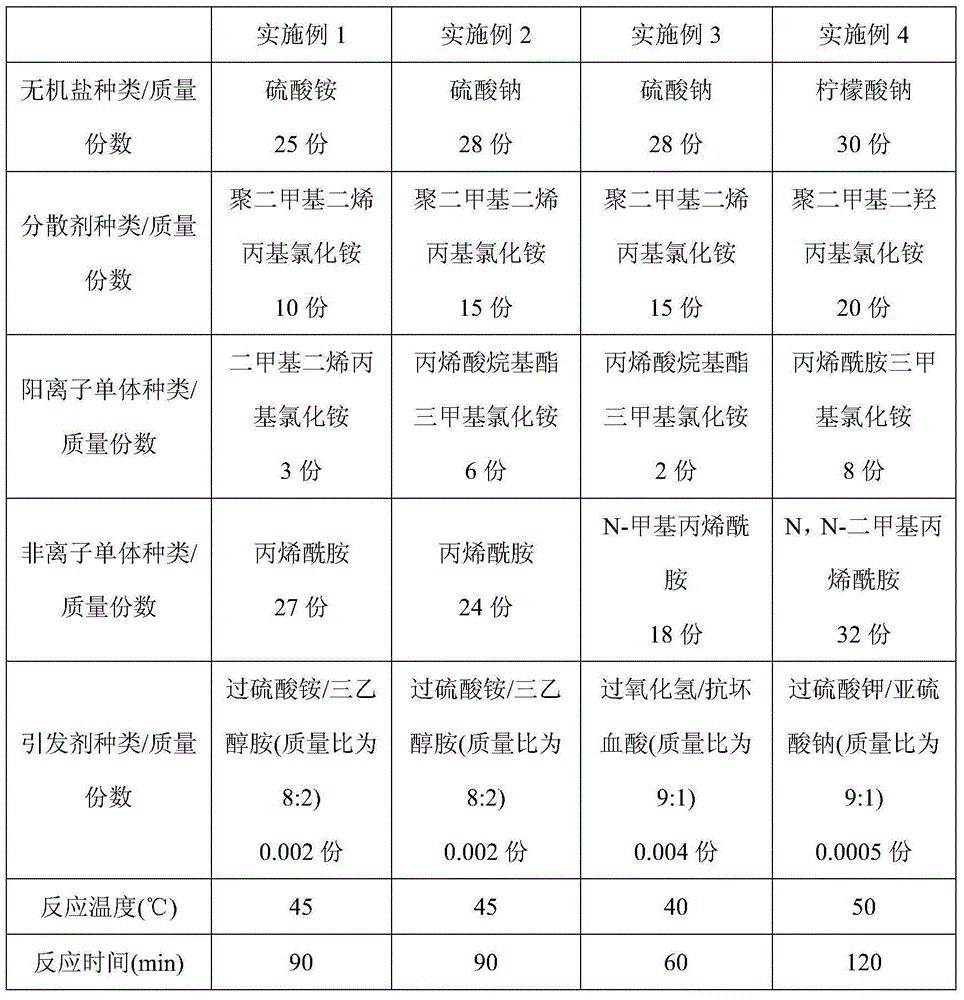

[0020] Examples 1-4 were implemented according to the following mass ratios and preparation conditions.

[0021]

[0022] The drag reducer prepared in Examples 1-4 was placed at room temperature for 3 months, sealed and kept away from light, and the appearance and system stability of the drag reducer were observed. The results are shown in Table 1.

[0023] The drag reducing agents prepared in Examples 1-4 were diluted 1000 times respectively, and a drag reducing agent solution with a mass concentration of 0.1% was prepared. The swelling endpoint was recorded when the viscosity of the solution no longer increased. The results are shown in Table 1.

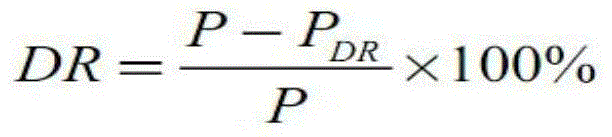

[0024] The drag-reducing performance of the drag-reducing agent is specifically manifested in the acceleration of the flow rate of the drag-reducing agent solution and the reduction of the frictional pressure drop. When the flow rate is constant, the drag-reducing effect is manifested in the reduction of the frictional pressure d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com