Novel ultra-hard sunlight screen

A new type of ultra-hard technology, applied in optics, optical components, electronic timers, etc., to improve anti-reflective light, improve wear resistance, and improve anti-reflective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

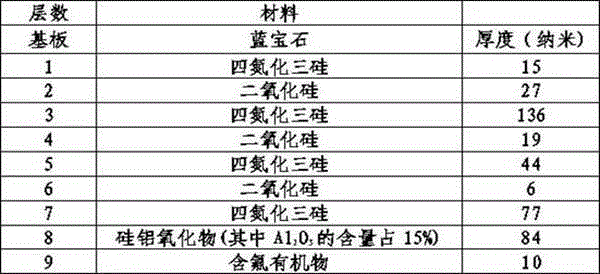

[0022] In this embodiment, sapphire is used as the screen of the display, and the film is coated on the sapphire substrate. Table 1 is the specific parameters of the film layer

[0023]

[0024] Table I

[0025] Preparation of silicon nitride film layer: Due to its multiple valence states, it may be Si 3 N x Where x=2-5, at the same time, this material is prone to absorption, when Si 3 N 4 When the valence state appears, the absorption is minimal and the hardness of the film is strong. So we Si 3 N 4 During the preparation, a sputtering silicon target is used, the flow rate of the working gas argon is 100-200 sccm, the flow rate of the reaction gas nitrogen is 100-150 sccm, the coating temperature is room temperature, and the bias voltage applied to the substrate is -100-200V.

[0026] Preparation of silicon dioxide film layer: Sputtering silicon target is used, the flow rate of argon gas of working gas is 100-200 sccm, the flow rate of oxygen gas of reaction gas is 1...

Embodiment 2

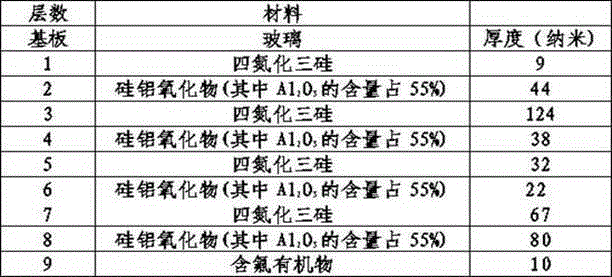

[0031] In this embodiment, glass is used as the screen of the display, and the film is coated on the glass substrate. Table 2 is the specific parameters of the film layer

[0032]

[0033] Table II

[0034] Si 3 N 4 Preparation: Sputtering silicon targets are used, the flow rate of argon as a working gas is 100-200 sccm, the flow rate of nitrogen as a reaction gas is 100-150 sccm, the coating temperature is room temperature, and the bias voltage applied to the substrate is -100-200V.

[0035] Silicon / aluminum oxide (wherein Al 2 o 3 content accounted for 55%) film preparation: silicon target and aluminum target sputtering at the same time, the power of the two targets is 2 ~ 15kw, the flow rate of the working gas argon is 100 ~ 200sccm, the flow rate of the reaction gas oxygen is 100 ~ 150sccm, the coating temperature It is room temperature, and the bias voltage applied to the substrate is -100 to -200V. Silicon / aluminum oxide (wherein Al 2 o 3 The content of content...

Embodiment 3

[0039] In this embodiment, transparent ceramics are used as the screen of the display, and the film is coated on the transparent ceramic substrate. Table 3 is the specific parameters of the film layer

[0040]

[0041] Table three

[0042] Si 3 N 4 During the preparation, a sputtering silicon target is used, the flow rate of the working gas argon is 100-200 sccm, the flow rate of the reaction gas nitrogen is 100-150 sccm, the coating temperature is room temperature, and the bias voltage applied to the substrate is -100-200V.

[0043] Silicon / aluminum oxide (wherein Al 2 o 3 content accounted for 21%)

[0044] The silicon target and the aluminum target are sputtered at the same time, the power of the two targets is 2-15kw, the flow rate of the working gas argon is 100-200 sccm, the flow rate of the reaction gas oxygen is 100-150 sccm, the coating temperature is room temperature, and the bias voltage applied to the substrate is -100~-200V. Silicon / aluminum oxide (wherein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com