Remote monitoring system for liquid ammonia tank

A remote monitoring system and liquid ammonia technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as production shutdown accidents, personal injury to equipment, casualties, etc., to save labor, ensure production safety, Reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

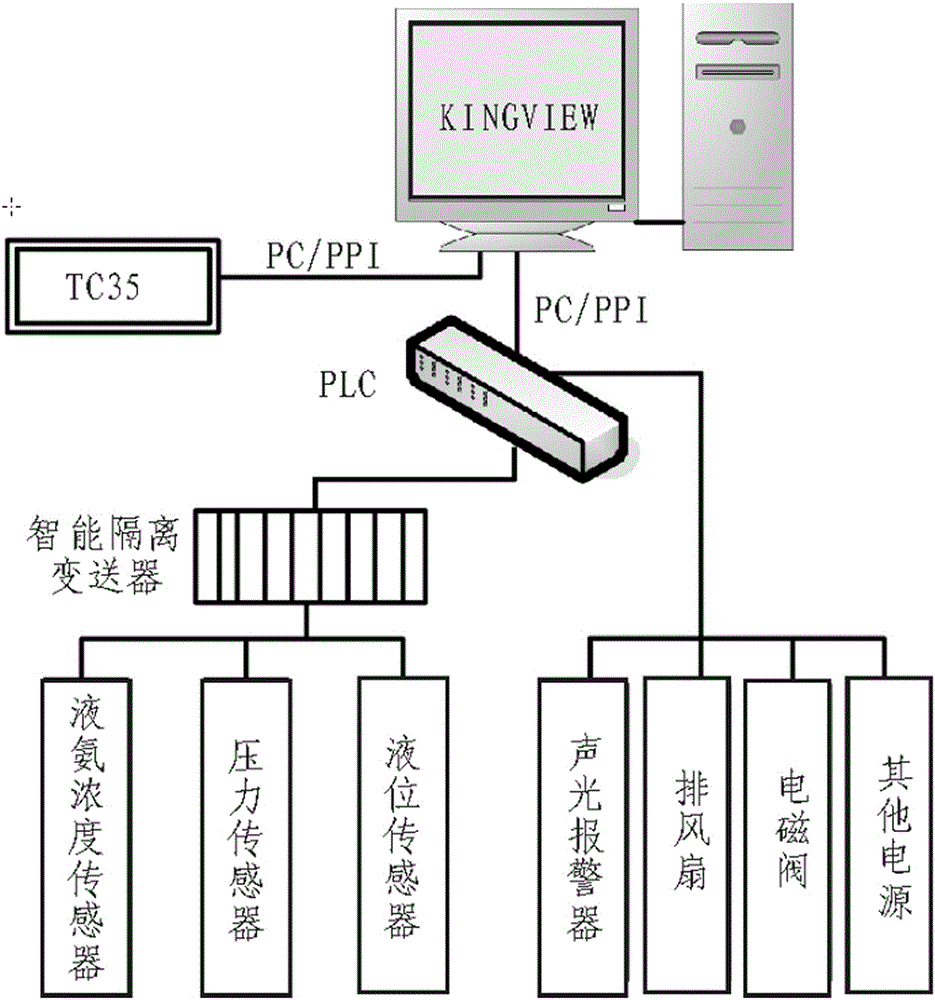

[0014] As shown in Figure 1, it is the overall structure diagram of a liquid ammonia storage tank remote monitoring system of the present invention. In the figure, it includes upper computer, PLC, pressure sensor, liquid level sensor, liquid ammonia concentration sensor, sound and light alarm, exhaust fan, solenoid valve, power supply; Ammonia tank remote monitoring screen, alarm screen, data report, trend curve screen, text message setting screen, dual serial port cards are installed on the host computer; Connected, the PLC is connected with an intelligent isolation transmitter; the signal input port of the PLC is respectively connected to the sound and light alarm, exhaust fan, solenoid valve, power supply, and the signal input port of the intelligent isolation transmitter is respectively connected to the pressure sensor, Liquid level sensor, liquid ammonia concentration sensor.

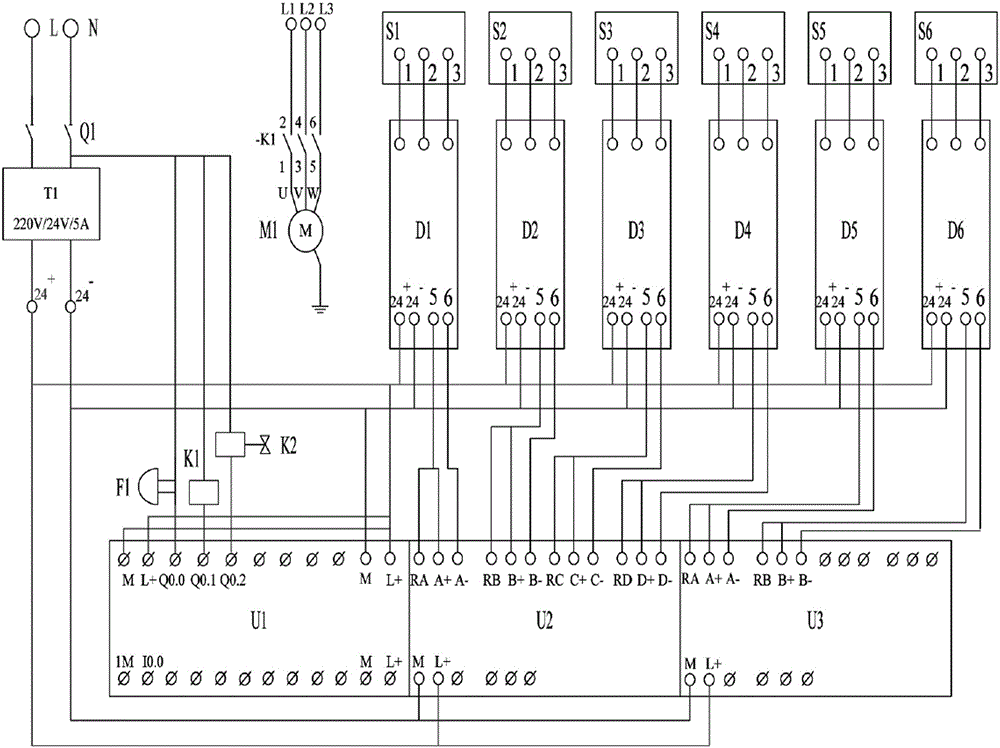

[0015] The PLC adopts Siemens S7-200 series CPU222 AC / DC / Relay type PLC, and the PLC includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com