Three-dimensional farm for raising animals

A kind of farm and three-dimensional technology, applied in the field of animal husbandry, can solve the problems of lack of three-dimensional intelligent breeding facilities, biogas slurry can not reach the temperature of gas production, and the surrounding environment has a greater impact, so as to achieve automatic feeding of feed and water, saving manpower , labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

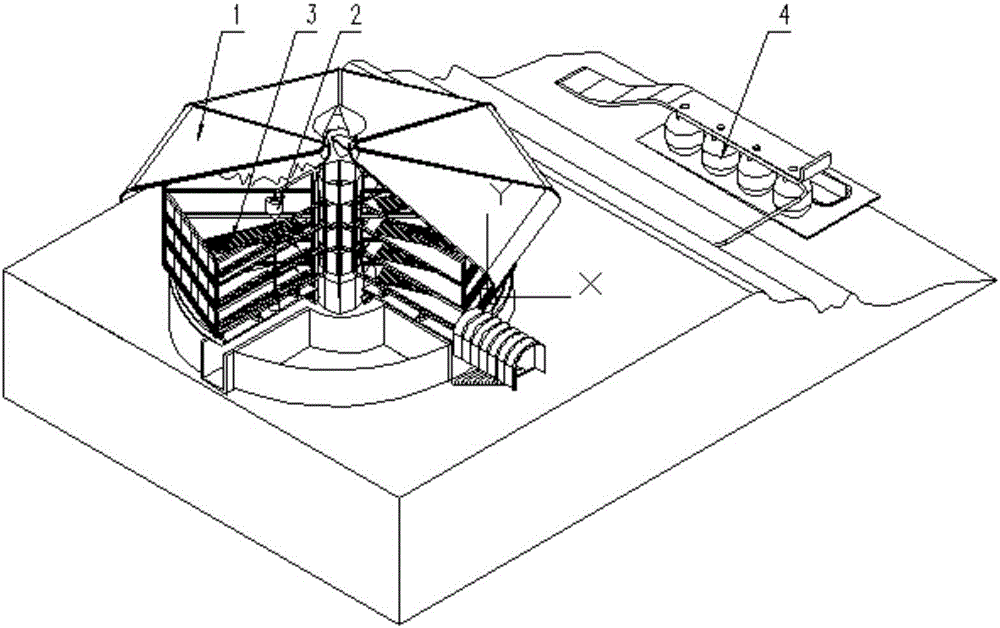

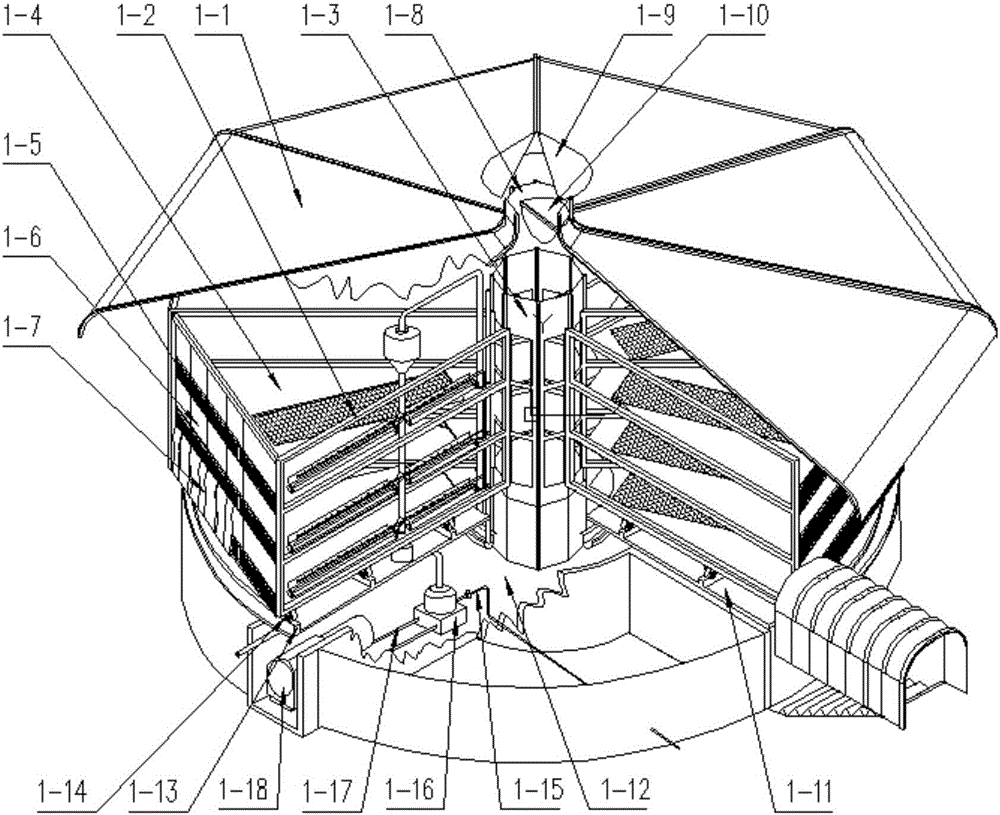

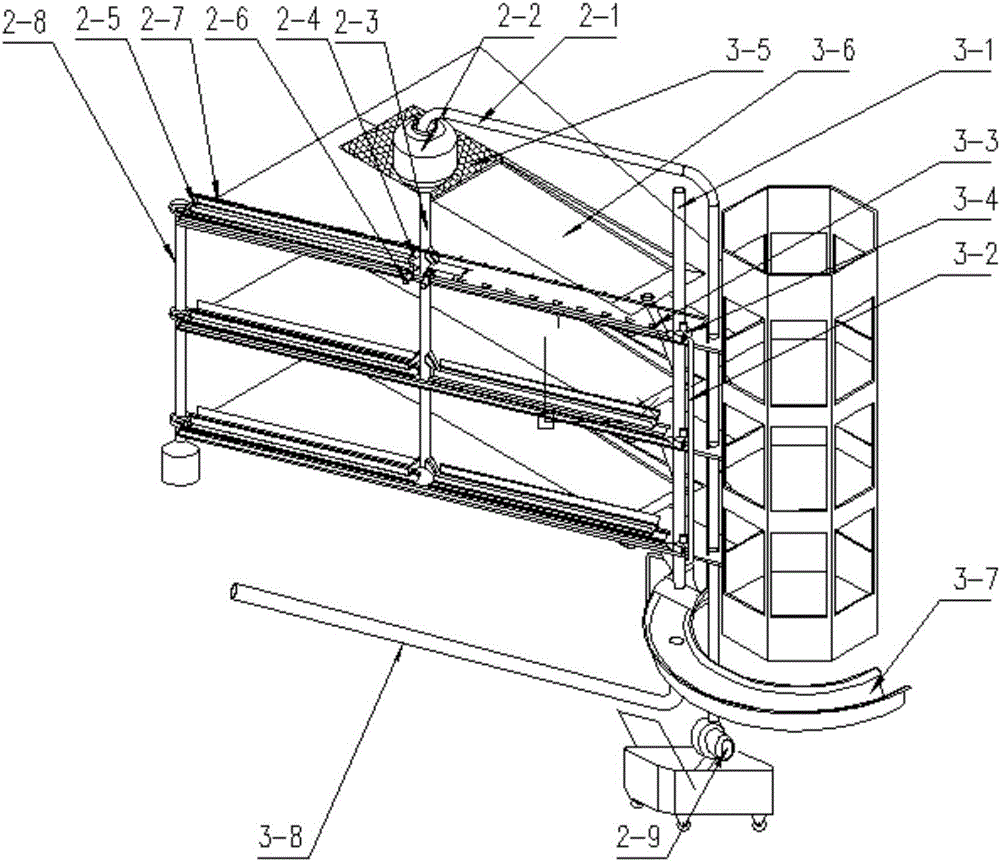

[0044] A three-dimensional animal husbandry farm includes a main structure 1, an automatic feeding device 2, a feces cleaning device 3 and a supporting biogas station 4 with a heating function, wherein the main structure 1 includes a translucent top plate 1-1, a metal frame 1-2, Elevator room 1-3, non-slip floor 1-4, guardrail 1-5, lighting window 1-6, sliding thermal insulation cotton curtain 1-7, top vent 1-8, rainproof cap 1-9, adjustable damper 1 -10, concrete base 1-11, basement 1-12, circular track 1-13, roller 1-14, biogas introduction pipe 1-15, biogas combustion heat exchanger 1-16, heat medium output pipe 1-17 and straight Gas turbine central air conditioner 1-18; among them, the translucent roof 1-1 is set on the upper part of the metal frame 1-2, the metal frame 1-2 is an octagonal metal frame, and the metal frame 1-2 on each floor is connected with the non-slip floor 1-4 constitute the breeding floor, the octagonal or circular elevator room 1-3 is located in the c...

Embodiment 2

[0051] The difference between this embodiment and embodiment 1:

[0052] The method for realizing the rotation of the cultivation layer is: when the cultivation layer is provided with multiple layers, each layer of cultivation layer includes a support, the support supports the floor, a cover plate is set on the top of the support, and a chute or a slide rail is arranged on the surface of the cover plate. The bottom of the first floor is provided with driving rollers and driven rollers, and the driving rollers and driven rollers roll in the chute or slide rail on the surface of the next layer of breeding layer cover plate respectively.

Embodiment 3

[0054] The difference between this embodiment and embodiment 1:

[0055] The method for realizing the rotation of the cultivation layer is: when the cultivation layer is provided with multiple layers, each layer of cultivation layer comprises a support, and the support supports the floor, and the top of each layer of cultivation layer support supports the bottom of the upper layer of cultivation layer, and at the bottom of the cultivation layer Rollers are set on the lower surface of the floor, slide rails or chute are set on the upper surface of the base, the rollers move in the chute or slide rail, and the hollow ring gear is fixed in the middle of the cultivation layer, the ring gear is connected with the motor through the gear, and the motor drives the rotation of the cultivation layer ; The bracket is a metal bracket, which can be spliced and installed, so that the culture layer becomes a closed or semi-closed hollow cylinder.

[0056] There are multiple flushing nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com