Set-up for converting horizontal milling into vertical milling

A milling and clamping technology, applied in the field of clamping tooling, can solve the problems of inability to obtain the required processing equipment, affecting the on-time delivery of tasks, objective conditions, etc., to achieve the effect of small deformation, stable installation, and reduced equipment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

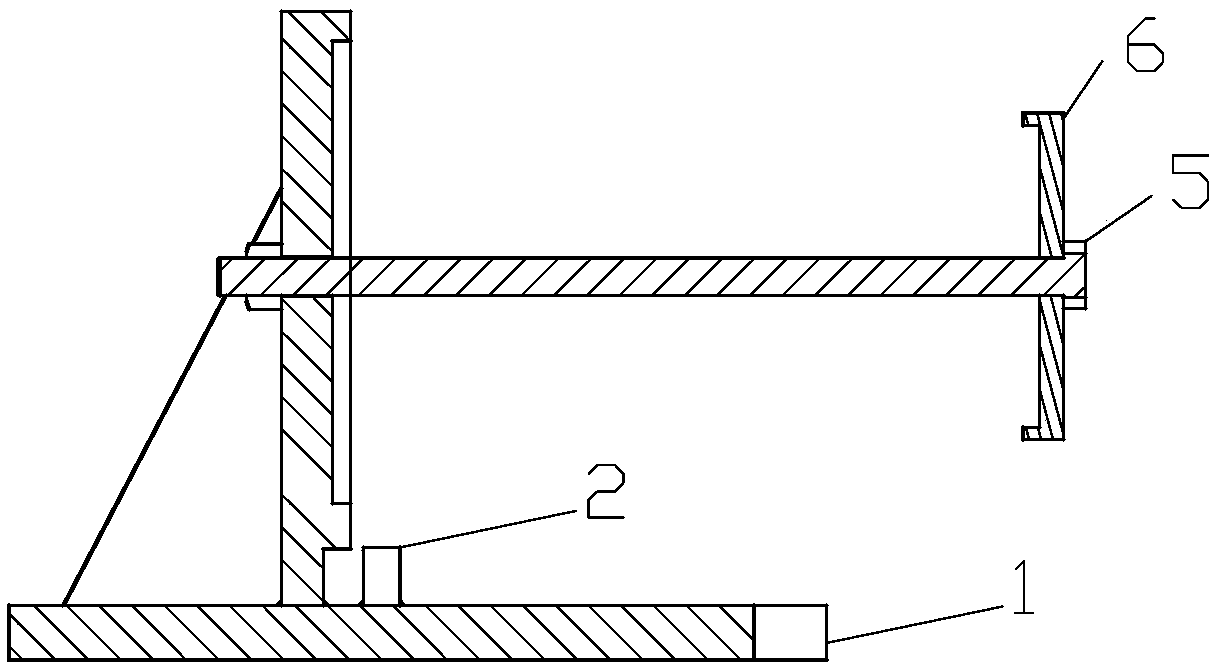

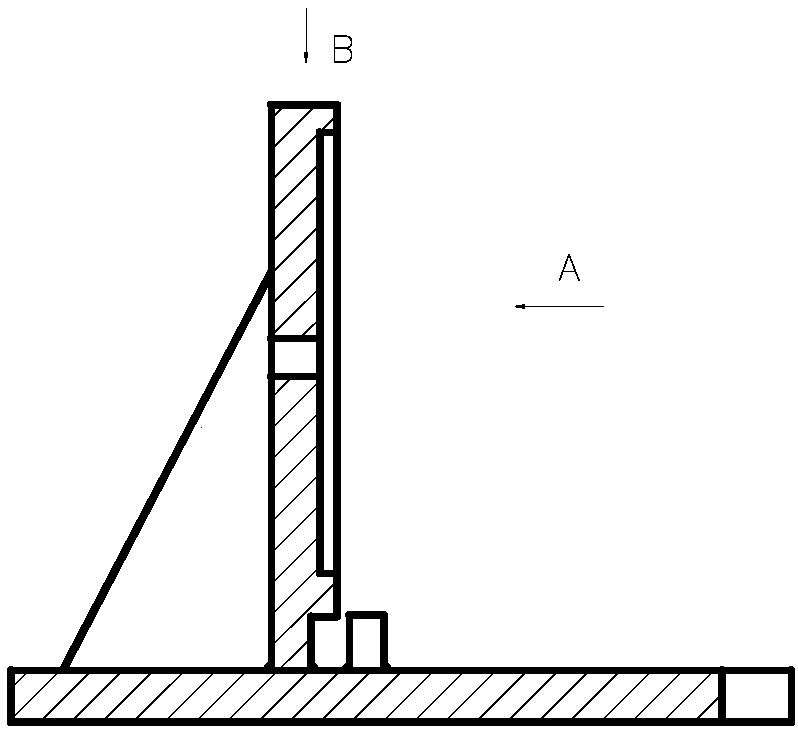

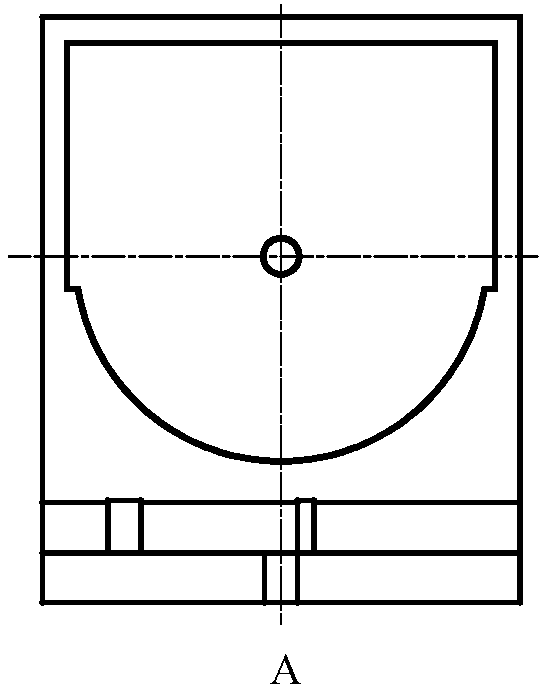

[0021] This embodiment is a clamping tool for converting horizontal milling into vertical milling, including a fixed support 1 , a positioning block 2 , a positioning screw seat 4 , a tie rod 5 and a threaded blocking cover 6 . There is a mounting hole for a pull rod 5 at the geometric center of the vertical plate of the fixed support 1, and one end of the pull rod is fixed in the mounting hole by a bolt; The distance between the inner surface of the assembled threaded plug and the inner surface of the vertical plate of the fixed support is adapted to the axial length of the workpiece 7 .

[0022] The fixed support 1 includes a horizontal plate and a vertical plate. The vertical board is located on the upper surface of the horizontal board. In order to ensure the stability of the vertical plate, there are supporting ribs between the outer surface of the vertical plate and the horizontal plate. A positioning blocking block 2 is fixed on the upper surface of the horizontal pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com