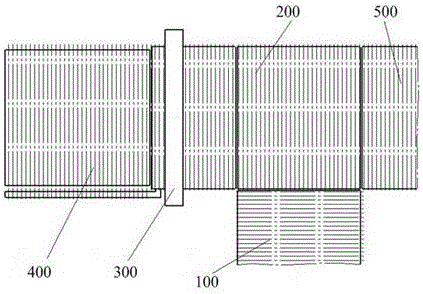

Unfired brick storage device

A billet storage and equipment technology, applied in conveyor objects, conveyors, mechanical conveyors, etc., can solve the problems of small billet storage and inability to meet emergency use requirements, so as to increase billet storage and save manpower and material costs. , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

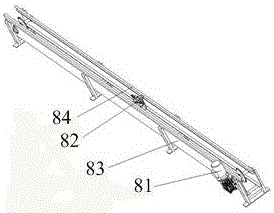

Method used

Image

Examples

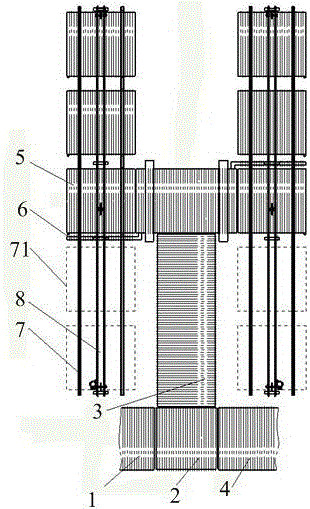

Embodiment 1

[0044] This embodiment discloses a billet storage device, the basic structure of which is the same as the above-mentioned structure, the difference is that there are two light rails provided in this embodiment, which are respectively located on both sides of the transition wire frame, one of which is the light rail There are 3 stockers on the top, which are the first stocker, the second stocker and the third stocker; there are 5 places for the stockers, and the full-load positions of the stockers are 2 1, respectively, the full load position of the first stocker and the full position of the second stocker; 1 loading and unloading position of the stocker, 2 empty positions of the stocker, the empty position of the first stocker and the second stocker Empty position, which is defined successively on the light rail as the full position of the second stocker, the full position of the first stocker, the loading and unloading position of the stocker, the empty position of the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com