Method for producing nail-free glue by universal glue

A technology of nail-free glue and universal glue, applied in the direction of non-polymer adhesive additives, adhesive additives, etc., can solve problems such as difficult viscosity, poor adaptability to the environment, and health hazards, and achieve adhesion and pull High tensile and shear strength, convenient production process operation, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

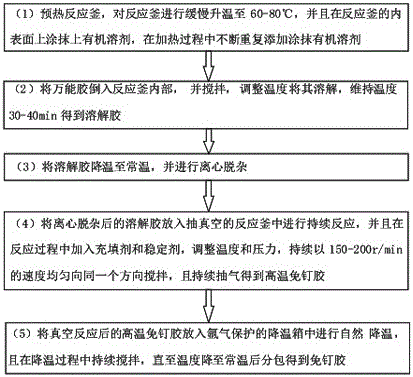

Image

Examples

Embodiment 1

[0024] A method for producing nail-free glue from universal glue, comprising the steps of:

[0025] (1) Preheat the reactor, slowly heat up the reactor to 60°C, and apply an organic solvent on the inner surface of the reactor, the organic solvent is selected from ethyl acetate, dimethyl carbonate or propyl acetate Any one, add and smear organic solvent repeatedly during the heating process;

[0026] (2) Pour the all-purpose glue into the reaction kettle and stir. The stirring rate is 100r / min, and it is always rotated and stirred in one direction during the stirring process. Adjust the temperature to dissolve it. Adjust the temperature to 140°C, and the average heating rate 10°C / min, maintain the temperature for 30min to obtain a dissolving gel, the viscosity of the dissolving gel is 10cP;

[0027] (3) Cool down the dissolving gel to room temperature, and perform centrifugation to remove impurities, and the centrifugation rate is 3000r / min;

[0028] (4) Put the dissolved gel...

Embodiment 2

[0031] A method for producing nail-free glue from universal glue, comprising the steps of:

[0032] (1) Preheat the reactor, slowly heat up the reactor to 70°C, and apply an organic solvent on the inner surface of the reactor, the organic solvent is selected from ethyl acetate, dimethyl carbonate or propyl acetate Any one, add and smear organic solvent repeatedly during the heating process;

[0033] (2) Pour the all-purpose glue into the reaction kettle and stir. The stirring rate is 110r / min, and it is always rotated and stirred in one direction during the stirring process. Adjust the temperature to dissolve it. Adjust the temperature to 150°C, and the average heating rate 10°C / min, maintain the temperature for 35min to obtain the dissolving gel, the viscosity of the dissolving gel is 12cP;

[0034] (3) Cool down the dissolving gel to room temperature, and perform centrifugation to remove impurities at a centrifugation rate of 3100r / min;

[0035] (4) Put the dissolved gel a...

Embodiment 3

[0038] A method for producing nail-free glue from universal glue, comprising the steps of:

[0039] (1) Preheat the reactor, slowly heat up the reactor to 80°C, and apply an organic solvent on the inner surface of the reactor, the organic solvent is selected from ethyl acetate, dimethyl carbonate or propyl acetate Any one, add and smear organic solvent repeatedly during the heating process;

[0040] (2) Pour the all-purpose glue into the reaction kettle and stir. The stirring rate is 120r / min, and it is always rotated and stirred in one direction during the stirring process. Adjust the temperature to dissolve it. Adjust the temperature to 160°C, and the average heating rate The temperature is 10°C / min, and the temperature is maintained for 40 minutes to obtain a dissolving gel, and the viscosity of the dissolving gel is 14cP;

[0041] (3) Cool down the dissolving gel to room temperature, and perform centrifugation to remove impurities at a centrifugation rate of 3200r / min;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com