Hydrocracking method for producing high-quality gasoline and diesel

A technology for hydrocracking and low-quality diesel oil, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment, etc. It can solve problems such as the difficulty in producing high-octane gasoline, supersaturation of polycyclic aromatic hydrocarbons, and harsh reaction conditions. Achieve the effect of reducing dry gas production, reducing hydrogen partial pressure, and avoiding secondary cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

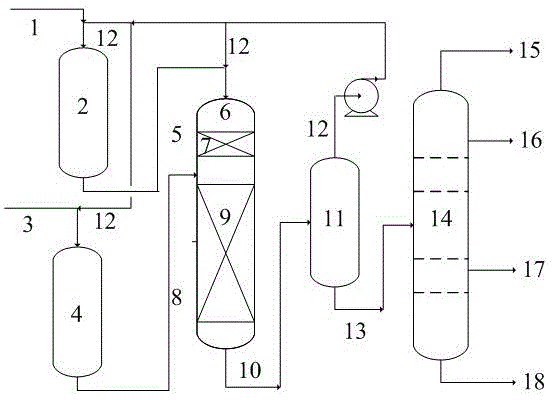

Image

Examples

Embodiment 1-2

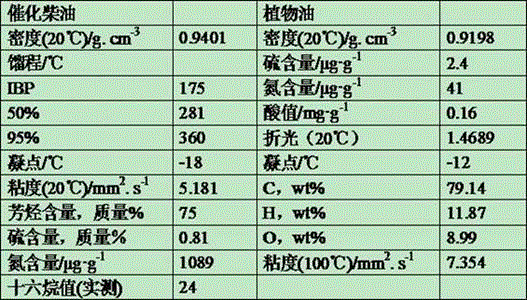

[0036] Examples 1-2 are examples of the method of the present invention, in which the weight ratio of animal and vegetable oil to inferior catalytic diesel is 1:1. Reference example 1 is the implementation effect of the catalytic diesel hydrogenation conversion technology, and reference example 2 is the implementation effect of the animal and vegetable oil hydrogenation upgrading technology. Table 1 shows the properties of the feedstock, Table 2 lists the properties of the hydrocracking catalyst used, and Table 3 lists the operating conditions and results.

[0037] Table 1 Raw oil properties.

[0038]

[0039] Table 2 Hydrocracking catalyst properties.

[0040]

[0041] Table 3 Operating conditions and results.

[0042]

[0043] *The lubricity in the vehicle diesel quality standard is generally characterized by the corrected wear scar diameter of 60°C, which is required to be no greater than 460μm.

[0044] The invention fully considers the respective characteristi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com