Hydro-upgrading method for production of low-condensation point motor fuel from biolipid

A bio-oil, hydrogenation and upgrading technology, applied in the field of hydrogenation, can solve the problems of shutdown replacement, influence of hydrogenation catalyst operation cycle, shortening operation cycle, etc., and achieve the effect of lowering the freezing point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

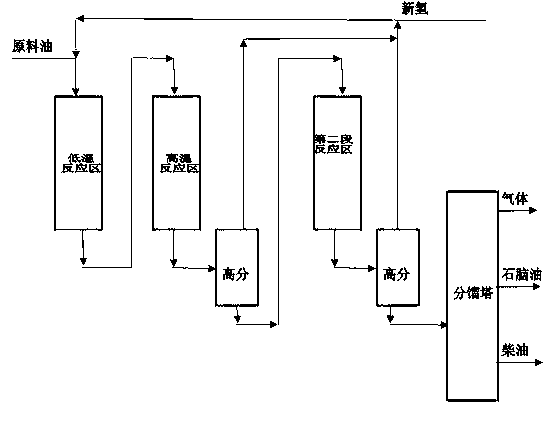

[0024] The method of the present invention is specifically as follows: using one or several mixed oils in the bio-grease as the raw material oil, under the hydrogenation operation condition, the raw material oil and hydrogen pass through the low-temperature and high-temperature hydrogenation reactors filled with catalysts, and the obtained hydrogenated The hydrogen-generated oil is recycled in the gas separated by the high-pressure separator (referred to as high fraction), and can also be discharged from the system. The obtained liquid fractionation is mixed with hydrogen and enters the second-stage reaction zone containing a hydrogenation-modifying catalyst with isomerization performance to obtain The gas separated from the hydrogenation and upgrading stream in the high-pressure separator (referred to as high fraction) can be recycled, and can also be discharged from the system, and the liquid can be fractionated to obtain the following products: one or more of gas, naphtha, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com