Method for synthesizing biodiesel through efficient catalysis of castor oil and ester exchange

A technology of castor oil ester and synthetic biology, applied in the direction of biofuel, petroleum industry, fatty acid production, etc., can solve the problems of restricting the use and promotion of biodiesel, secondary pollution by-products, poor low-temperature fluidity, etc., to improve stability and Catalytic activity, overcoming the effect of low catalytic activity and low freezing point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

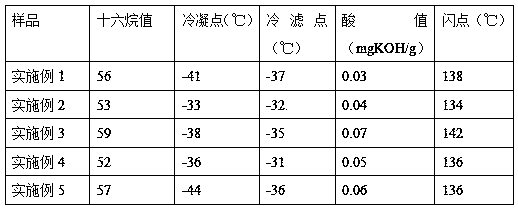

Examples

Embodiment 1

[0032] A method for efficiently catalyzing castor oil transesterification to synthesize biodiesel oil, comprising the following steps:

[0033] (1) Add castor oil and 85°C hot water into the treatment tank, the amount of hot water added is 30% of the weight of castor oil, stir at high speed for 20 minutes, let it stand for stratification, take the upper layer of oil and then perform centrifugation;

[0034] (2) Add the grease obtained after centrifugation to the agitator, and then add a treatment agent composed of polyacrylamide and activated clay with a mass ratio of 1:2. The amount of the treatment agent added is 3% of the weight of castor oil, Heat up to 100°C, keep warm and stir for 15 minutes, filter and separate to obtain pure castor oil;

[0035] (3) Put pure castor oil, methanol and catalyst into the reactor according to the mass ratio of 100:60:1, react at a temperature of 100°C and a speed of 250r / min for 1.5h, centrifuge, let stand and separate into layers, and the ...

Embodiment 2

[0039] A method for efficiently catalyzing castor oil transesterification to synthesize biodiesel oil, comprising the following steps:

[0040] (1) Add castor oil and 90°C hot water into the treatment tank, the amount of hot water added is 25% of the weight of castor oil, stir at high speed for 30 minutes, let stand for stratification, take the upper layer of oil and then carry out centrifugation;

[0041] (2) Add the grease obtained after centrifugation to the agitator, and then add a treatment agent composed of polyacrylamide and activated clay with a mass ratio of 1:3. The amount of the treatment agent added is 2% of the weight of castor oil, Heat up to 90°C, keep warm and stir for 20 minutes, filter and separate to obtain pure castor oil;

[0042] (3) Put pure castor oil, methanol and catalyst into the reactor at a mass ratio of 100:50:1.2, react for 3 hours at a temperature of 80°C and a rotation speed of 300r / min, centrifuge, stand to separate layers, and the upper layer i...

Embodiment 3

[0046] A method for efficiently catalyzing castor oil transesterification to synthesize biodiesel oil, comprising the following steps:

[0047] (1) Add castor oil and 80°C hot water into the treatment tank, the amount of hot water added is 35% of the weight of castor oil, stir at high speed for 20 minutes, let stand for stratification, take the upper layer of oil and then carry out centrifugation;

[0048] (2) Add the grease obtained after centrifugation to the agitator, and then add a treatment agent composed of polyacrylamide and activated clay with a mass ratio of 1:3. The amount of the treatment agent added is 3.2% of the weight of castor oil, Heat up to 100°C, keep warm and stir for 10 minutes, filter and separate to obtain pure castor oil;

[0049] (3) Put pure castor oil, methanol and catalyst into the reactor according to the mass ratio of 100:55:1.5, react at a temperature of 100°C and a speed of 150r / min for 1 hour, centrifuge, stand and separate layers, and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com