Patents

Literature

62results about How to "Solve the problem of not being able to operate stably for a long period of time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogenation method for producing biological grease by motor fuel

ActiveCN102464996ASolve the problem of not being able to operate stably for a long period of timeBiofuelsLiquid hydrocarbon mixture productionOil and greaseHydrogenation reaction

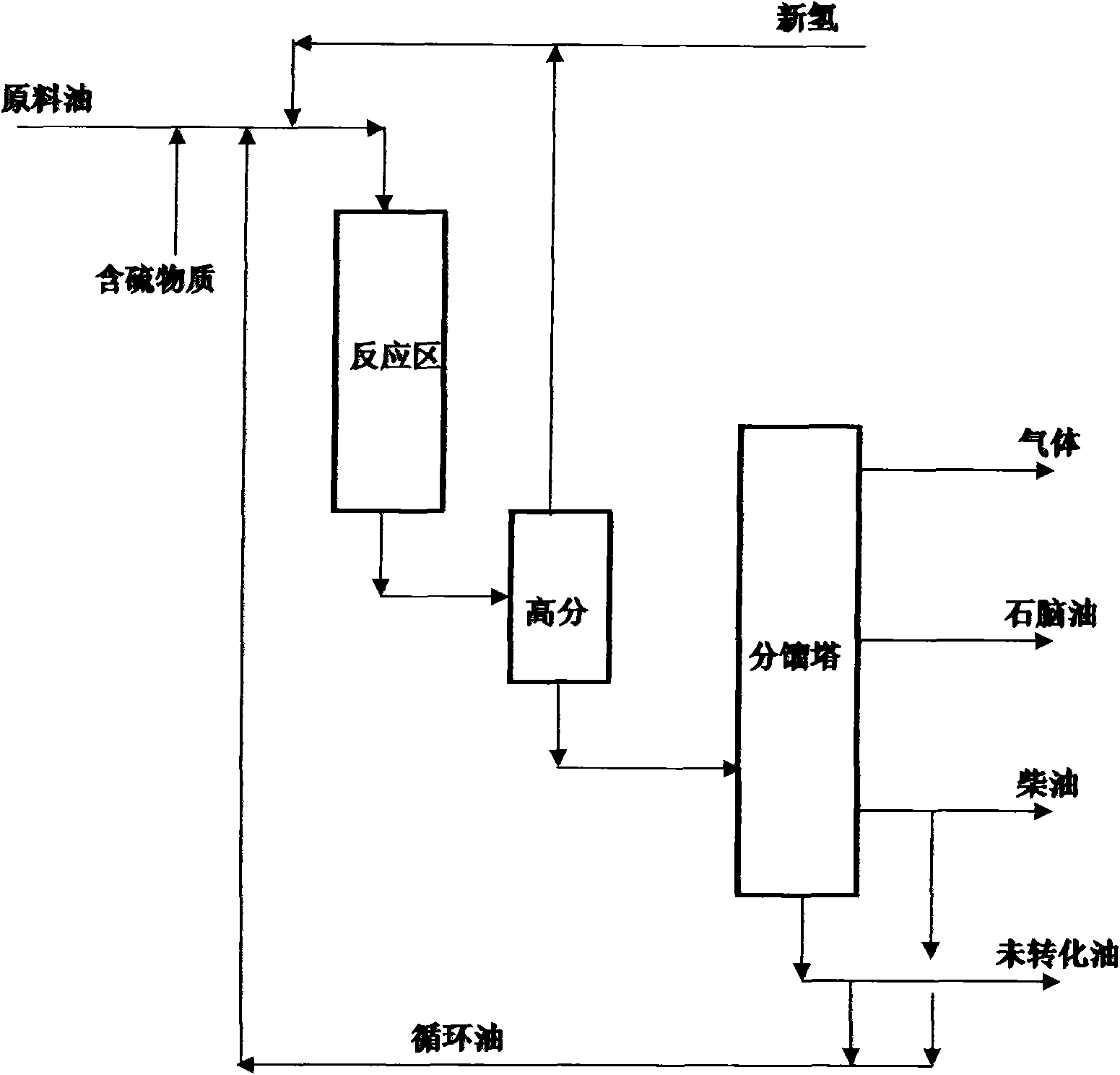

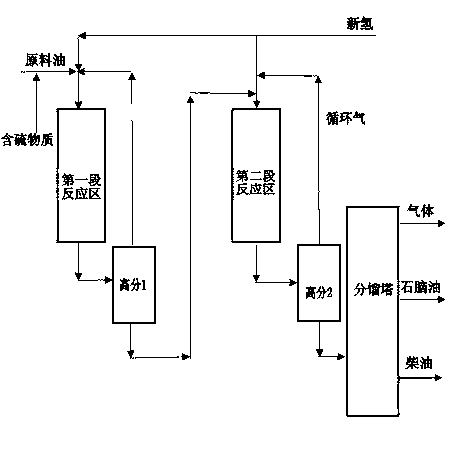

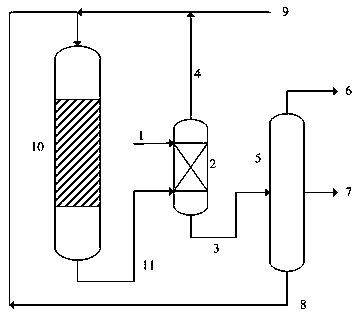

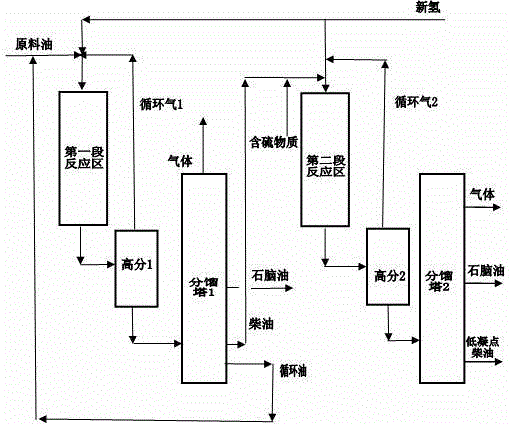

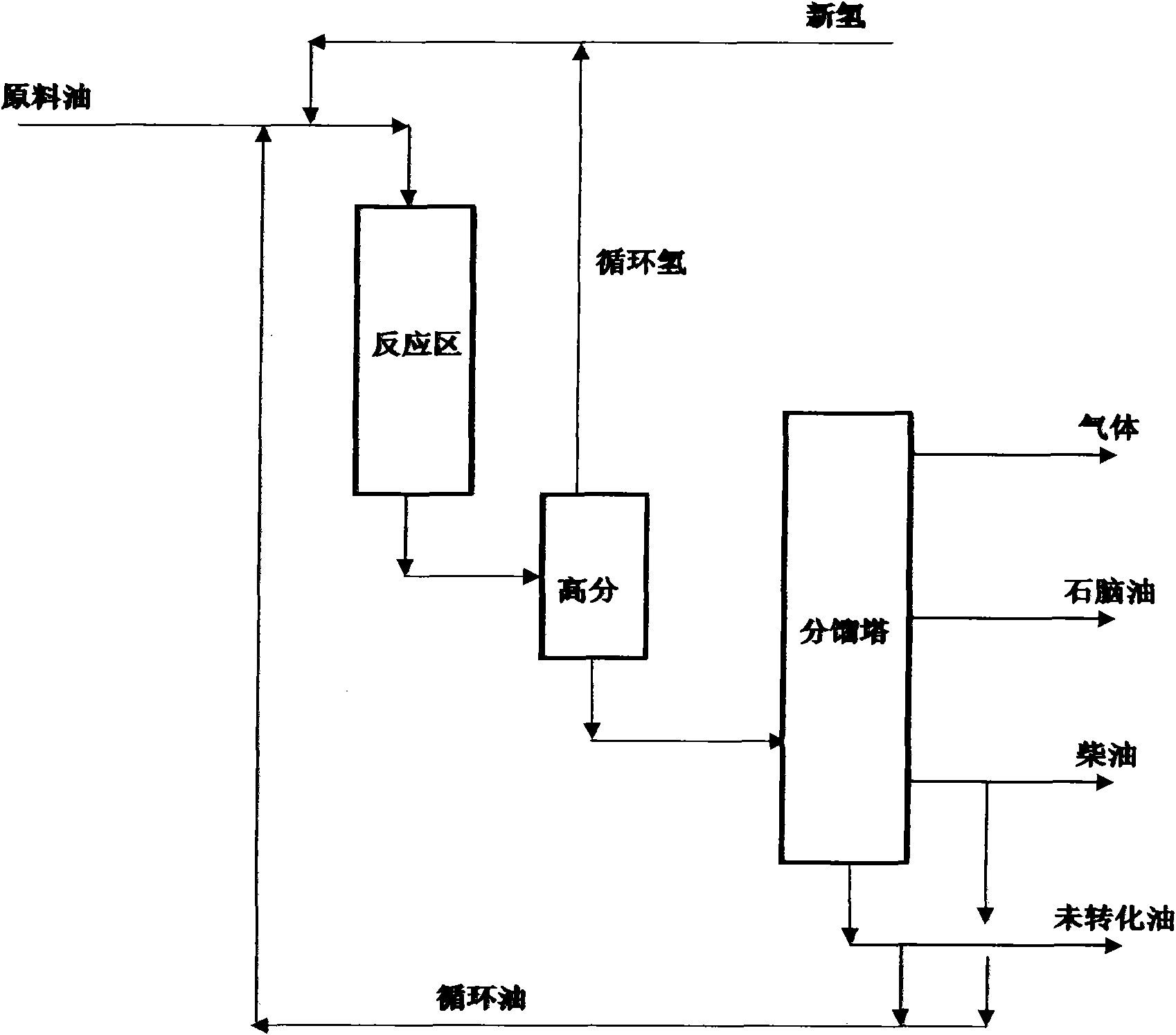

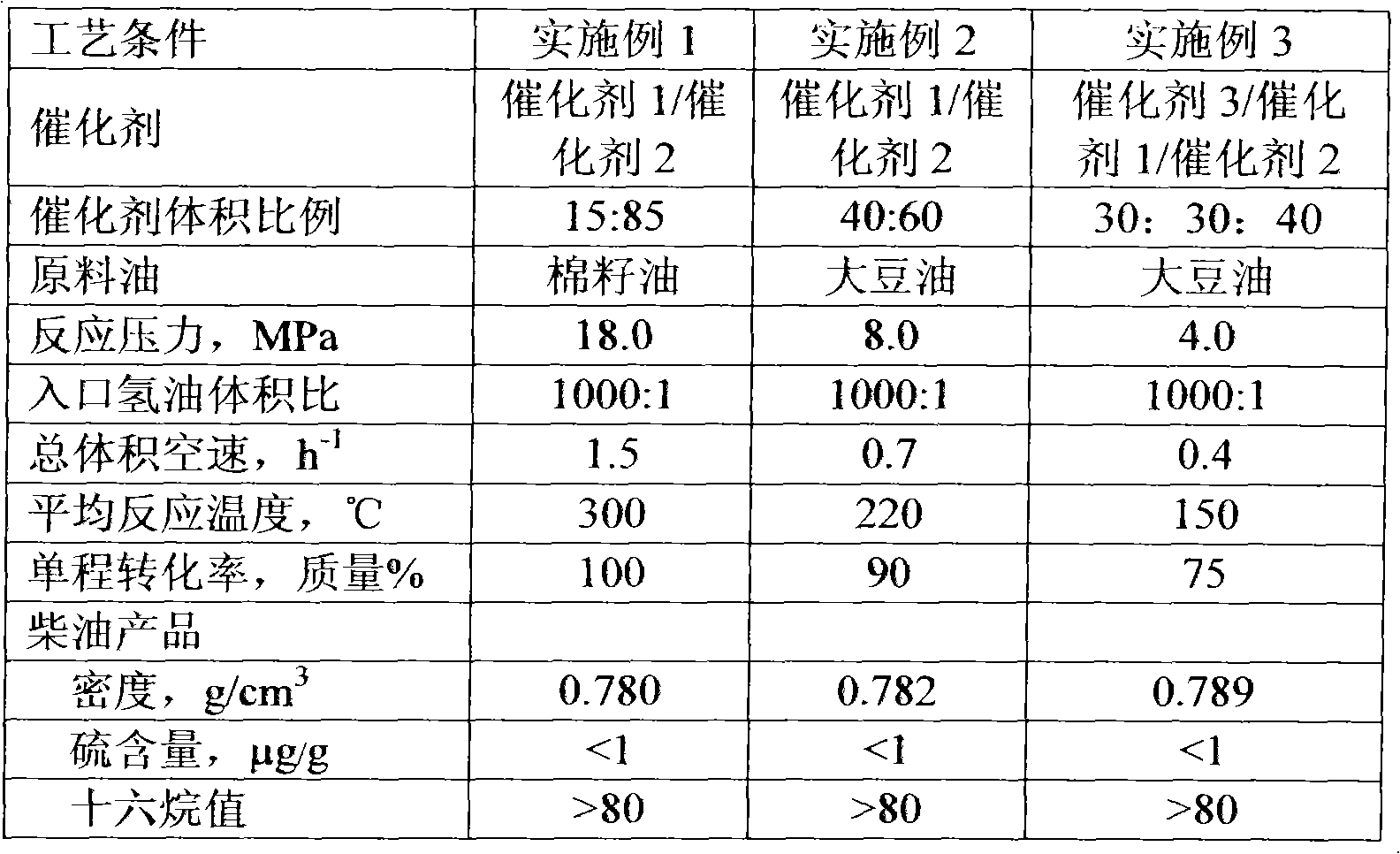

The invention relates to a hydrogenation method for producing biological grease by motor fuel. The method is characterized in that the biological grease is taken as a raw oil, under the hydrogenation condition, the raw oil and hydrogen are mixed and passed through a hydrogenation reaction zone, oil is generated by hydrogenation and separated to obtain hydrogen-rich gas for circularly using, the separated liquid is directly produced to the motor fuel. Compared with the prior art, the hydrogenation method for producing the biological grease by motor fuel is capable of effectively improving the storage stability by taking animal and plant grease as the fuel oil, simultaneously ensuring the long-time stable operation of a hydrogenation apparatus.

Owner:CHINA PETROLEUM & CHEM CORP +1

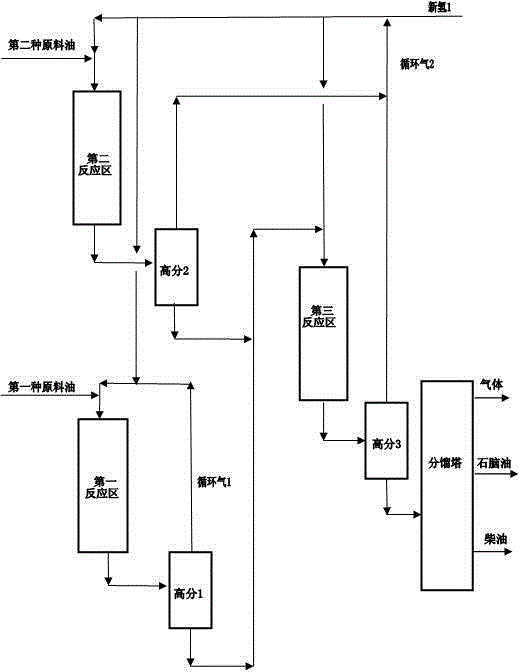

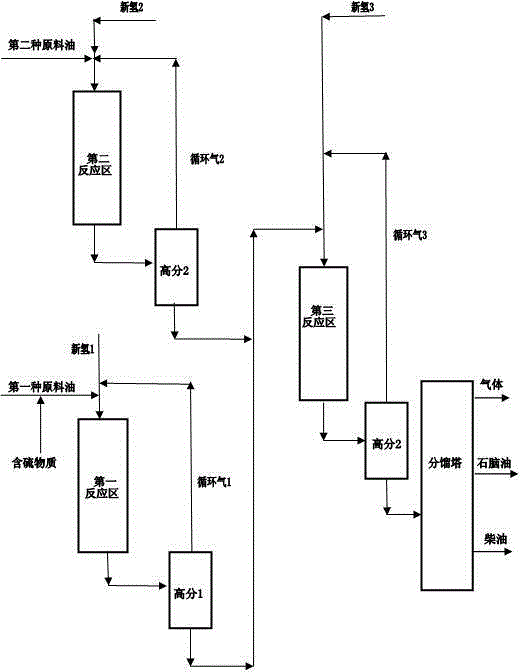

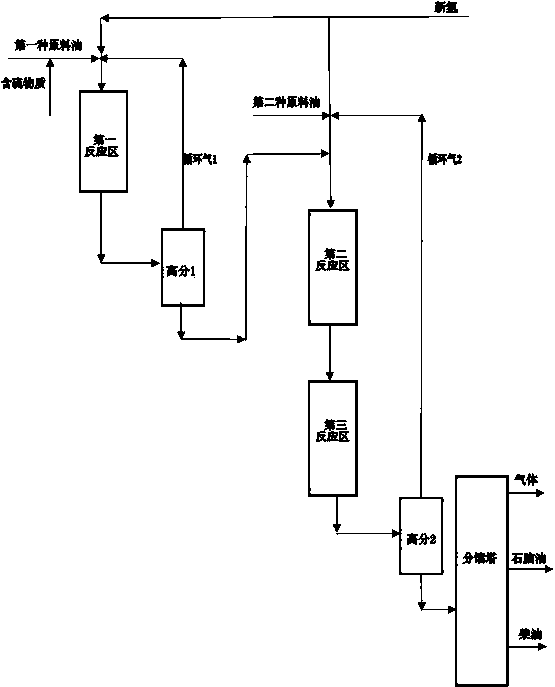

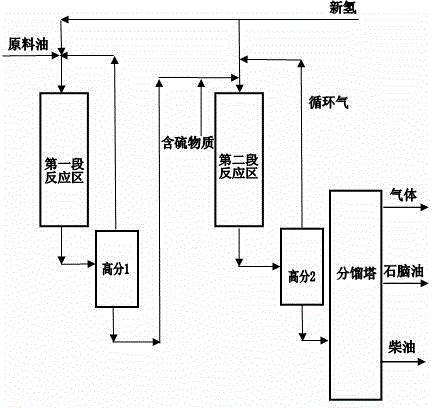

Hydrogenation method for producing motor fuel from biological grease

ActiveCN102464997ASolve the problem of not being able to operate stably for a long period of timeLiquid hydrocarbon mixture productionBio-feedstockOil and greaseGas phase

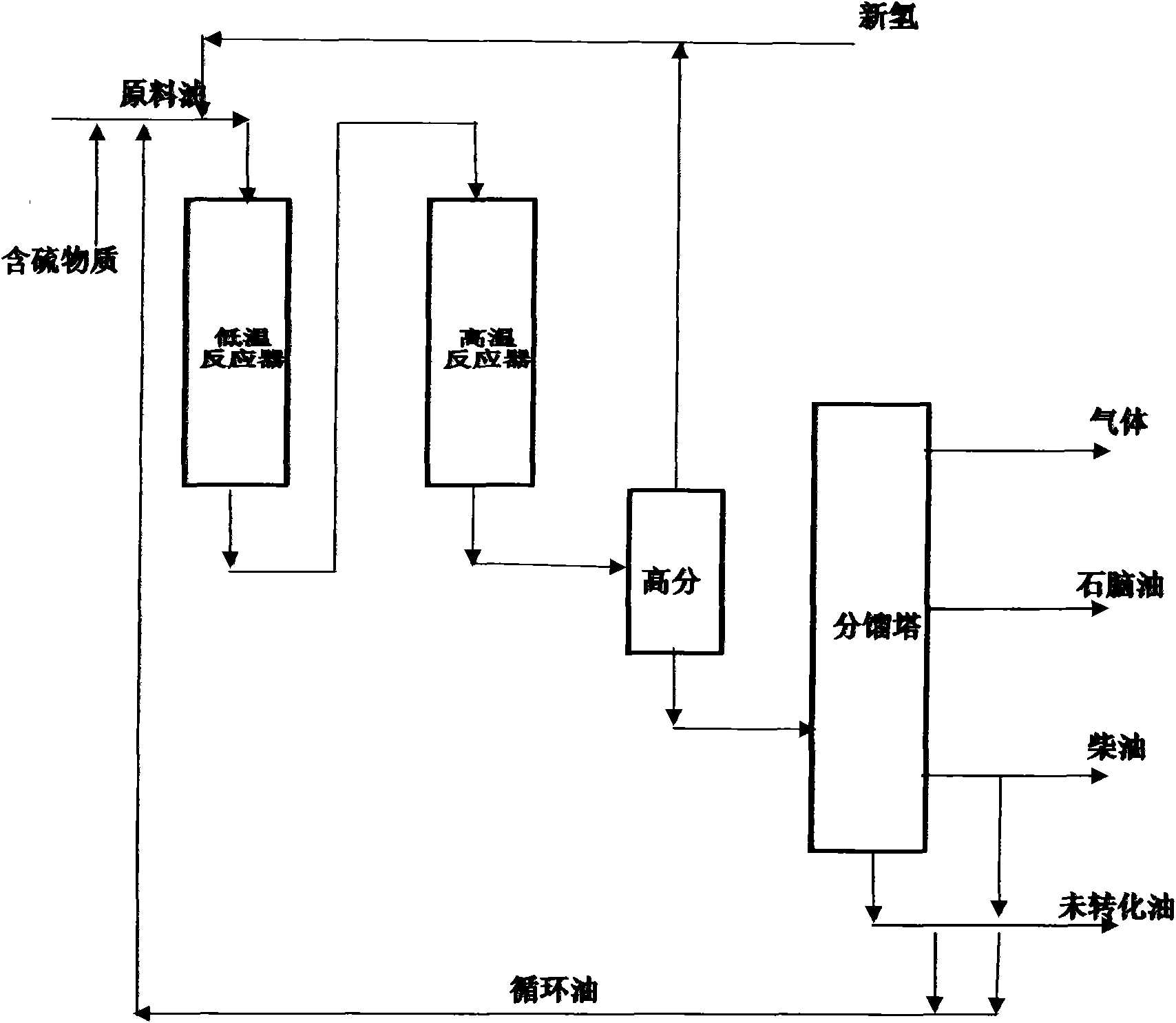

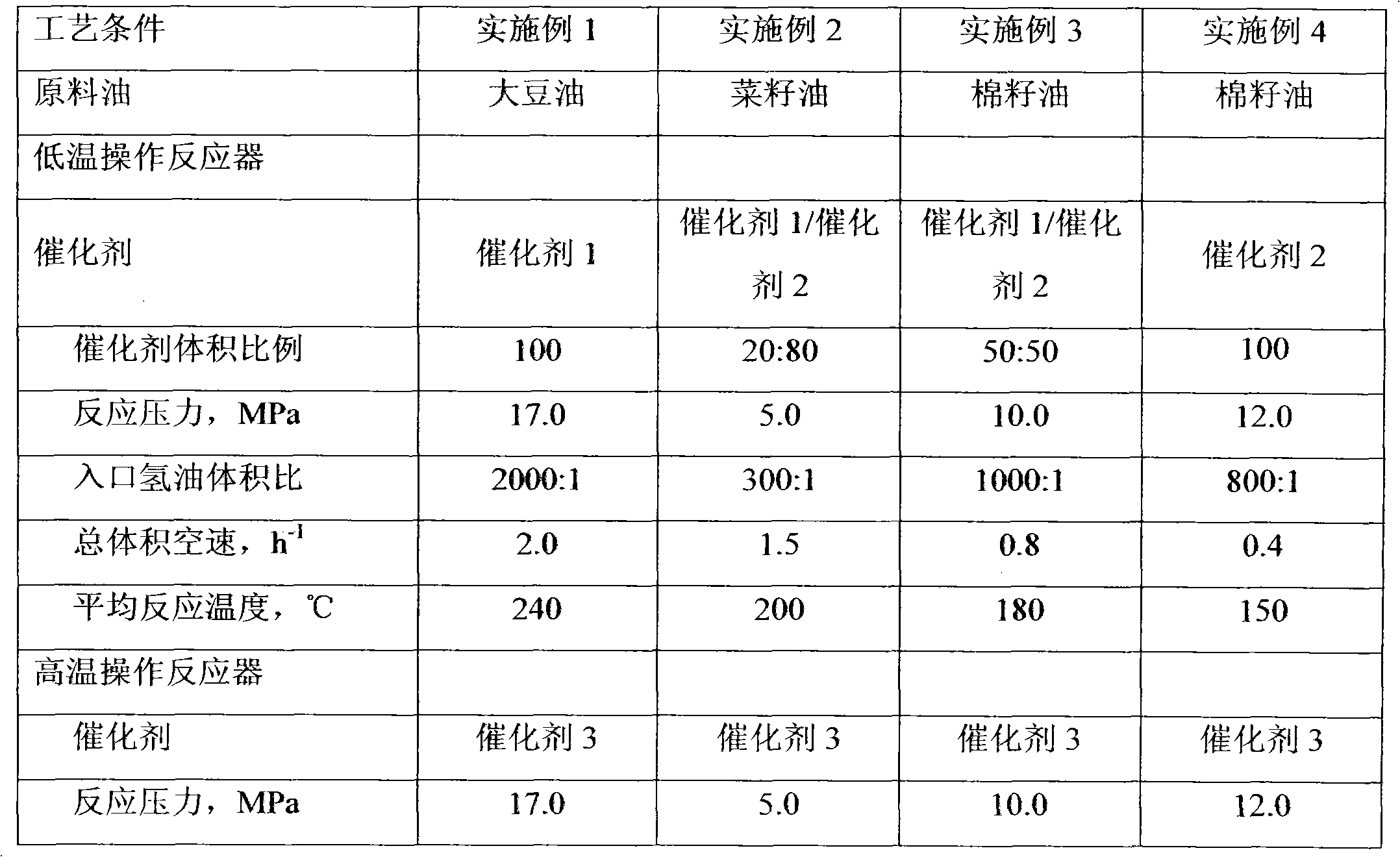

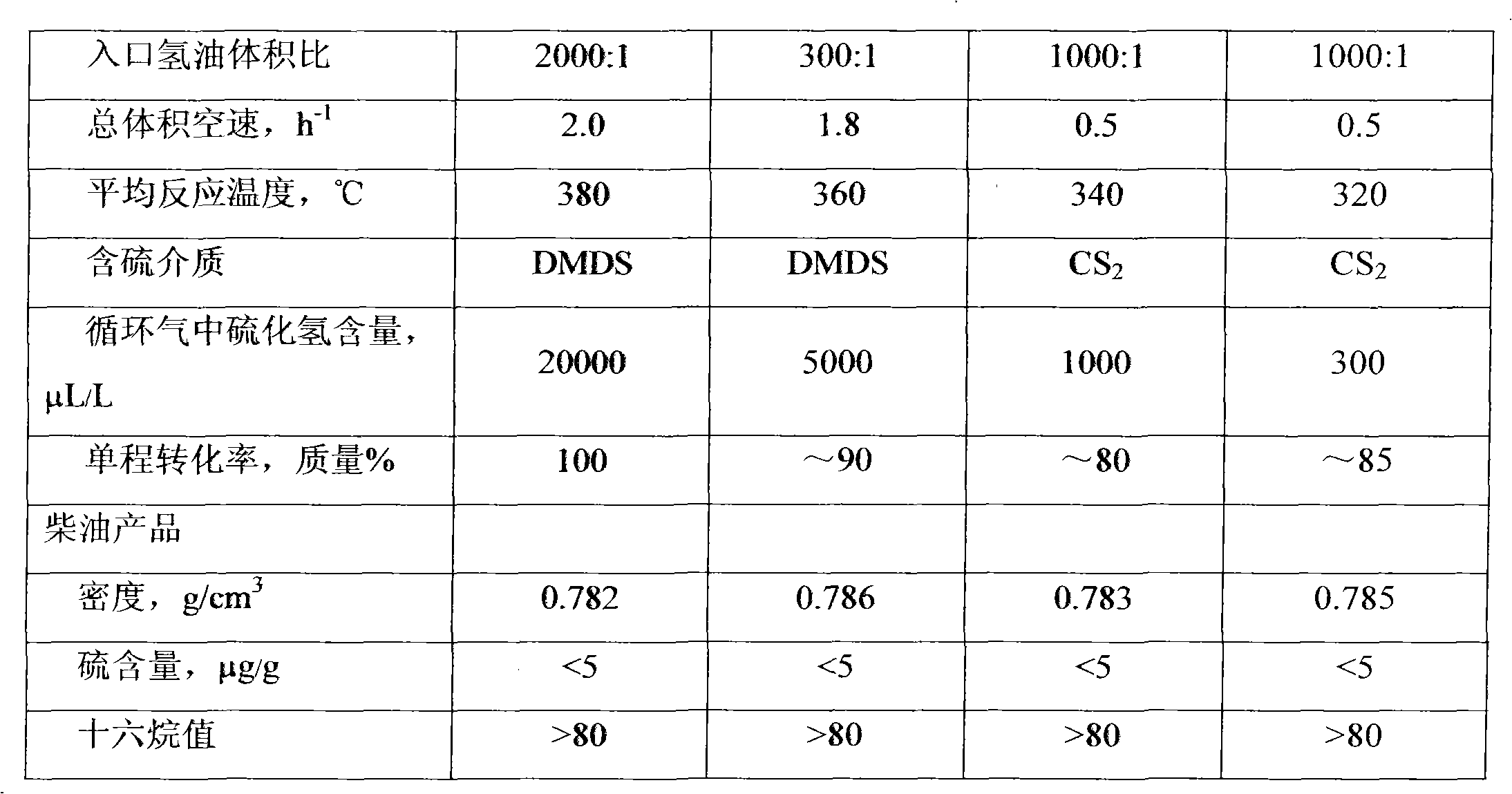

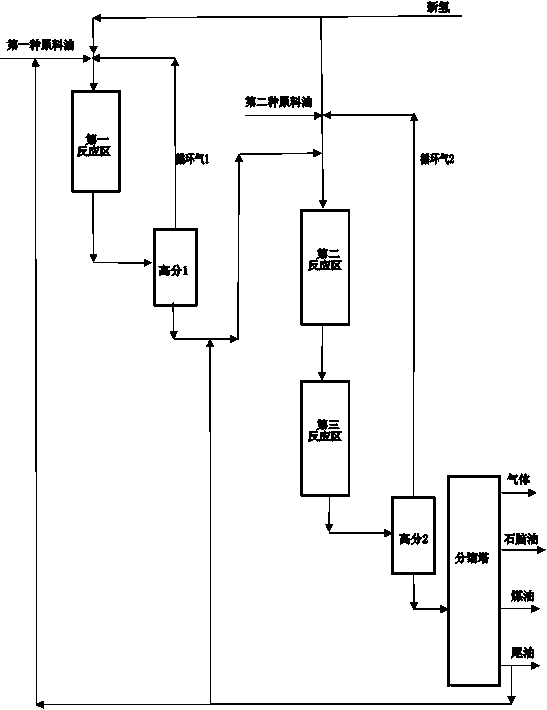

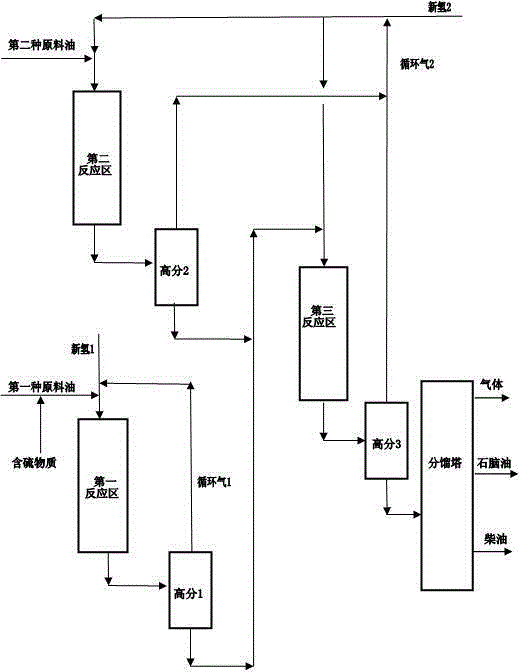

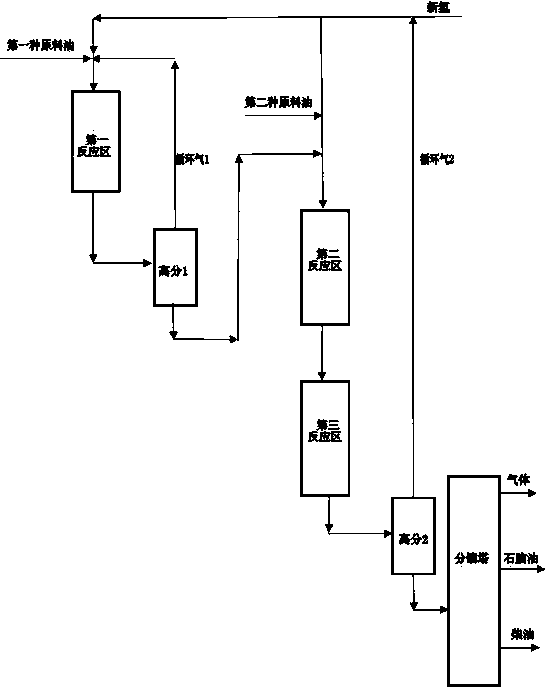

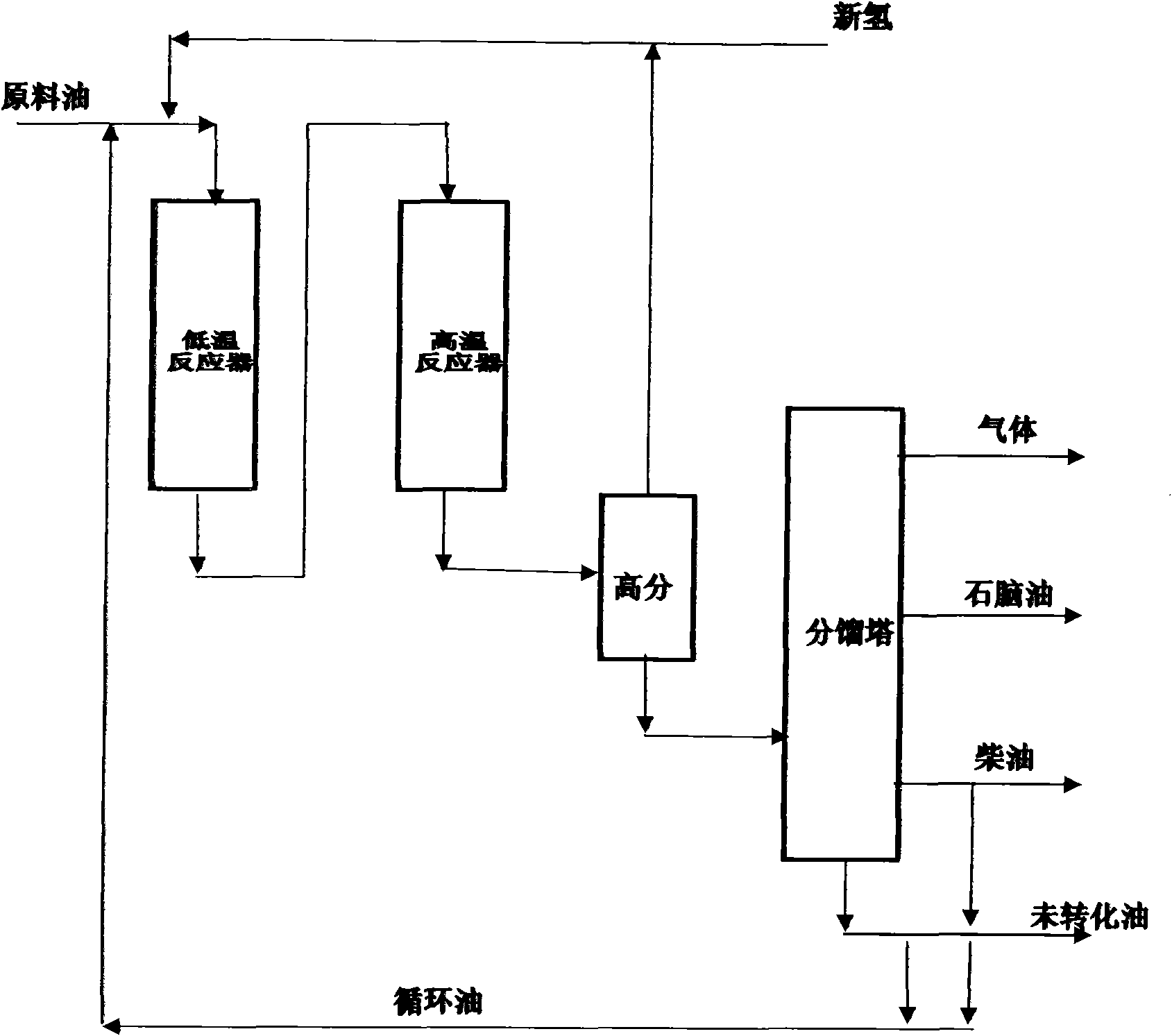

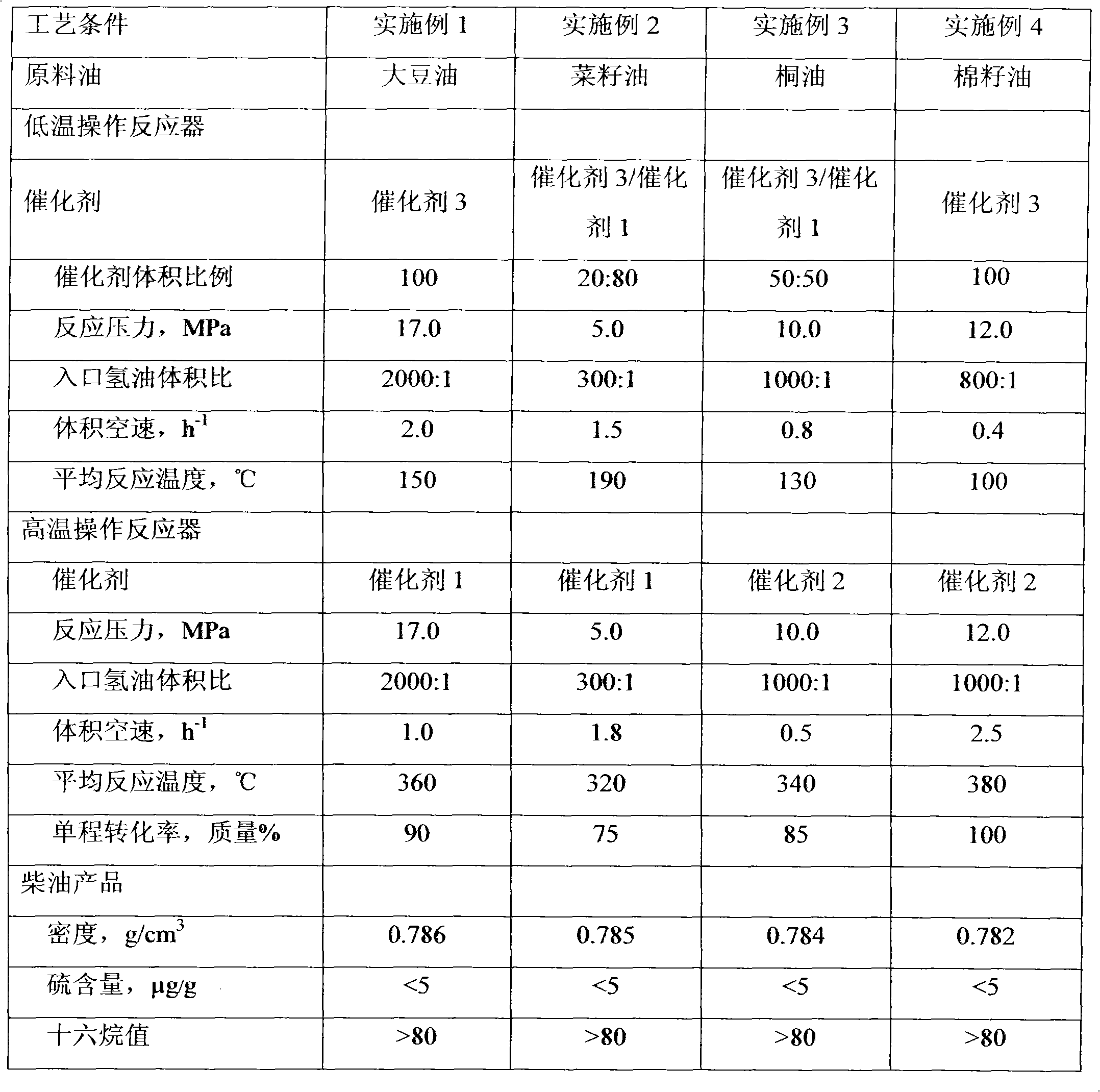

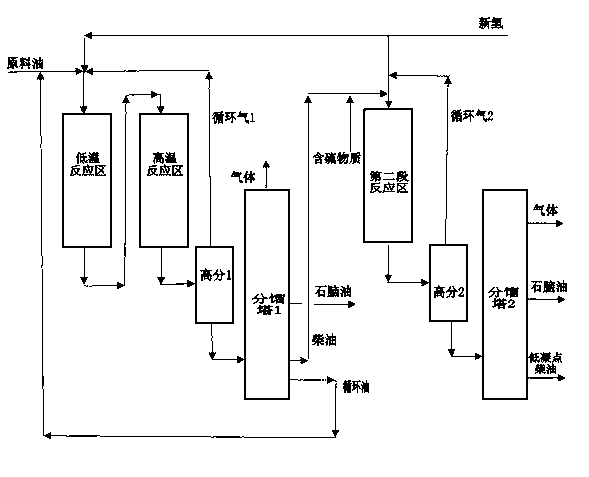

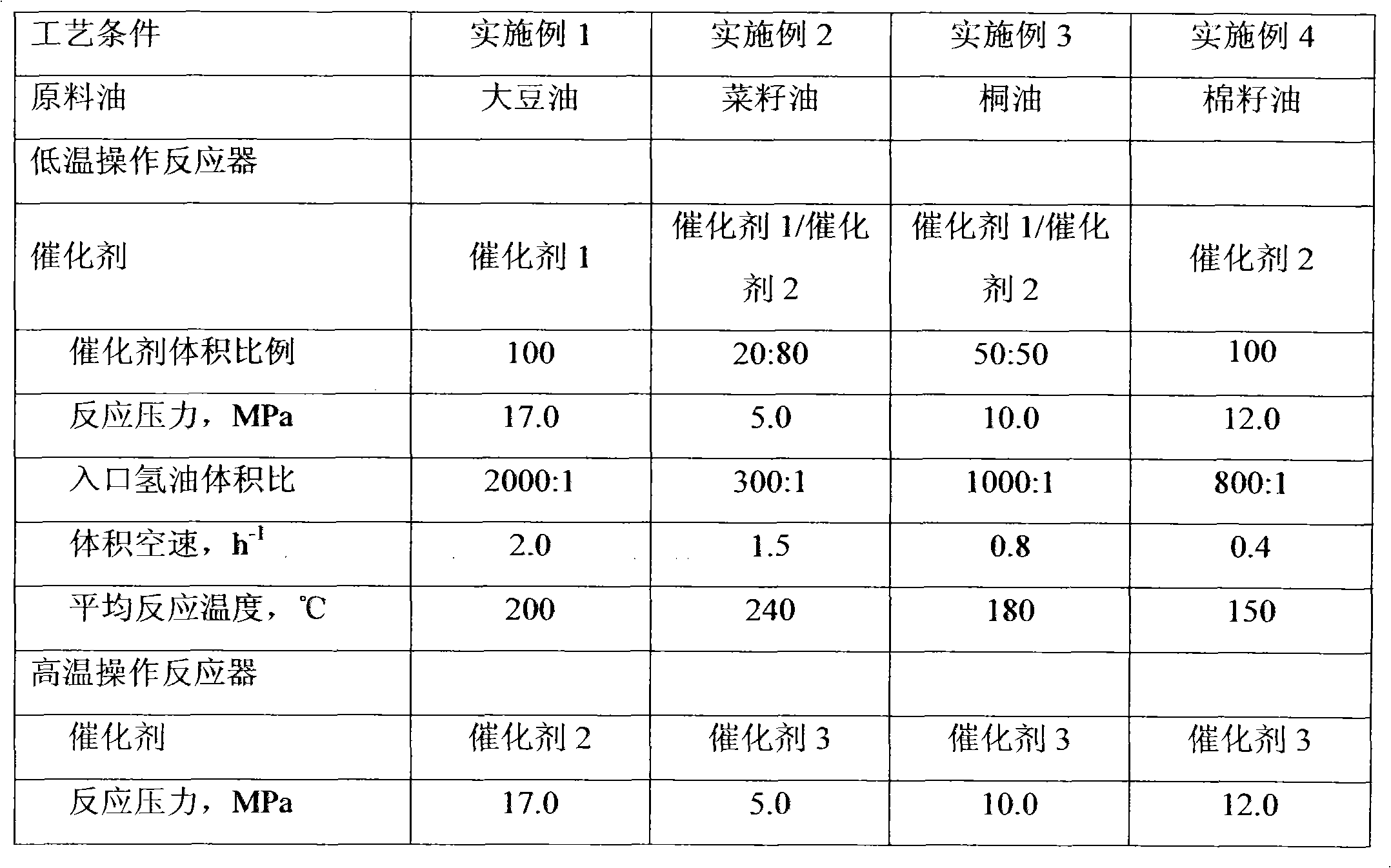

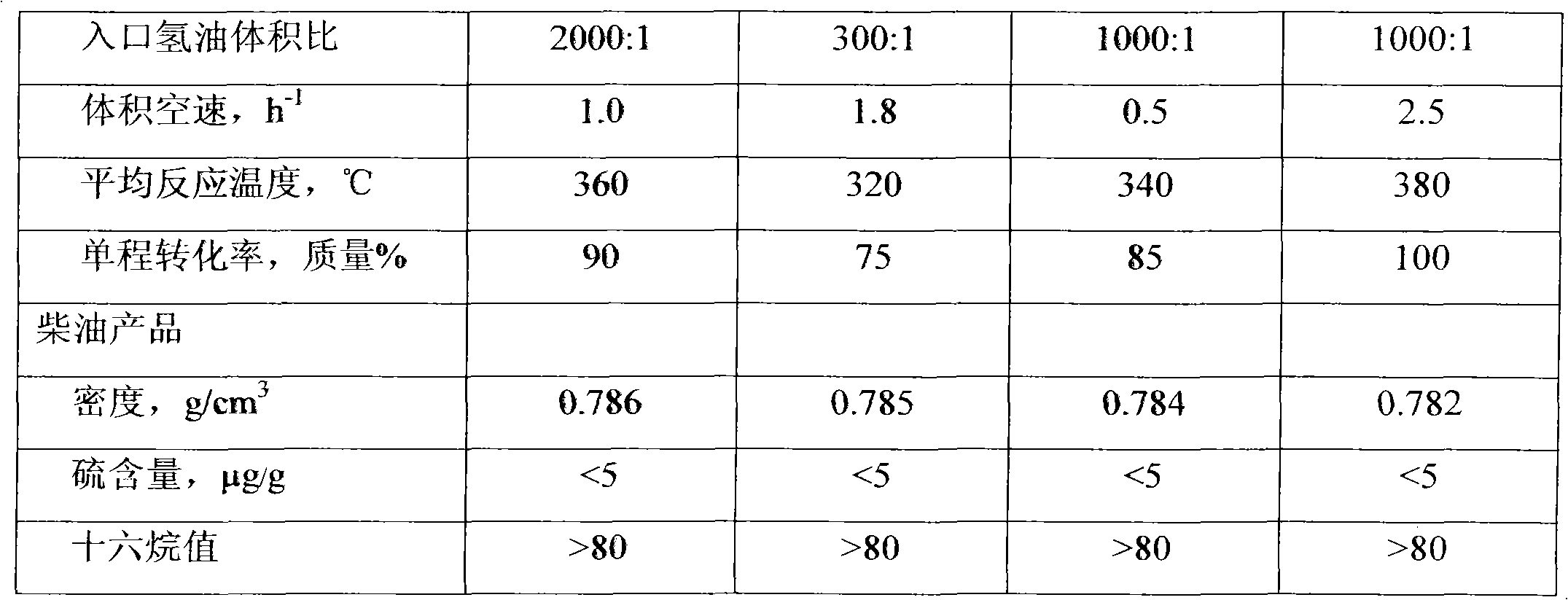

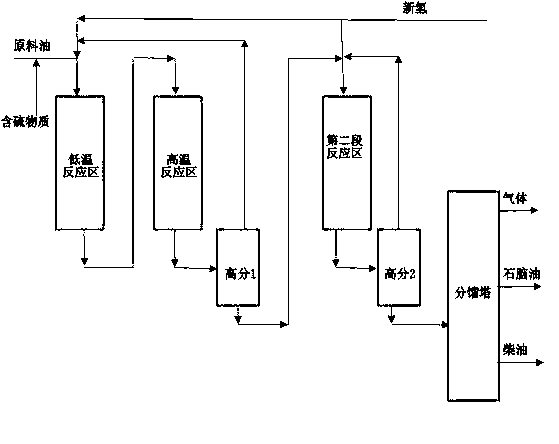

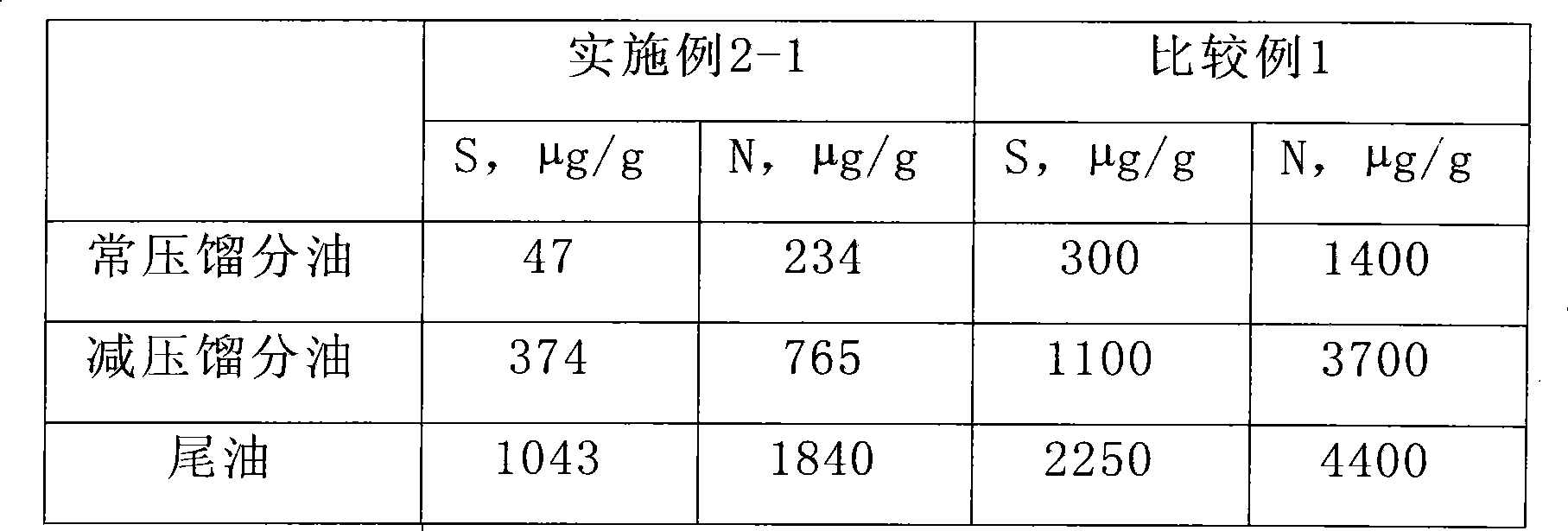

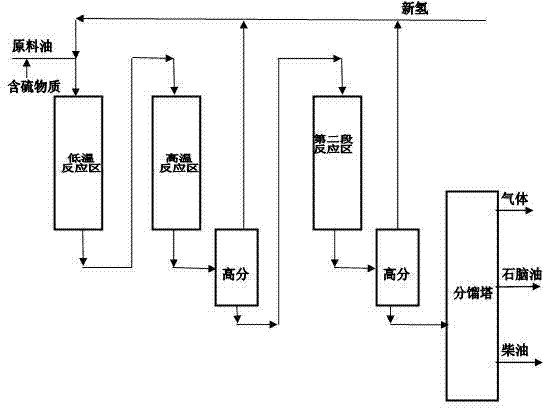

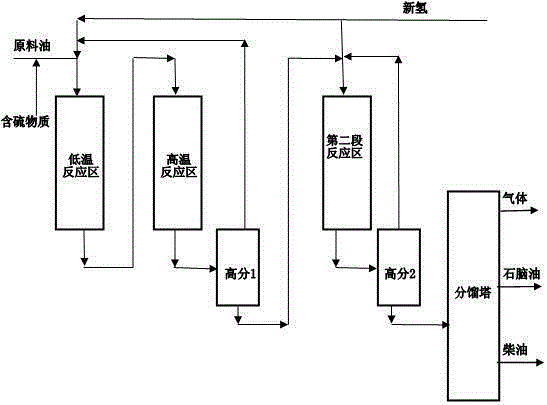

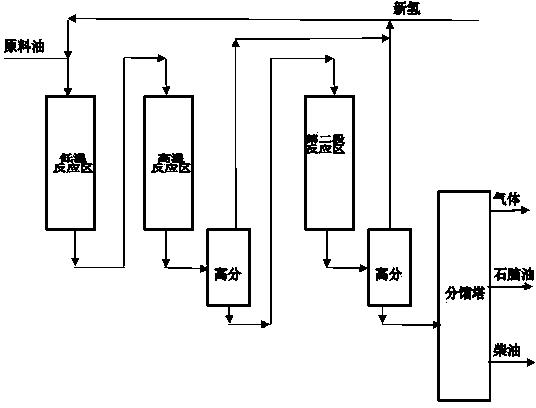

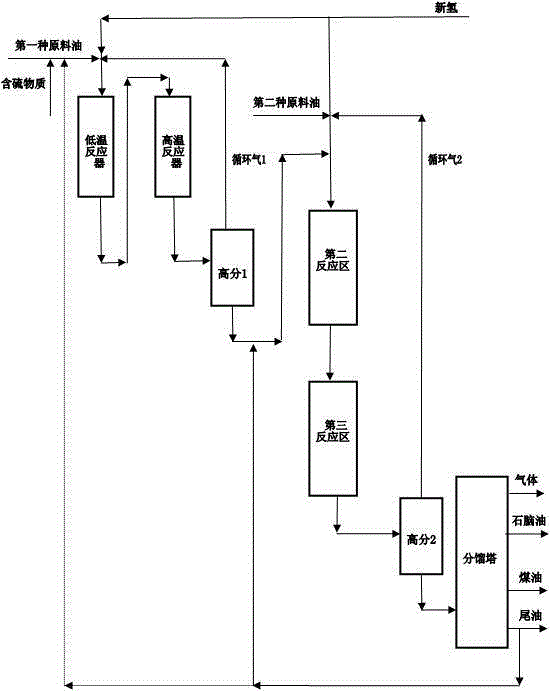

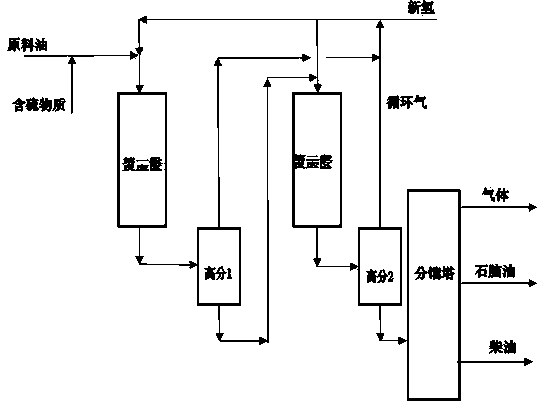

The invention relates to a hydrogenation method for producing a motor fuel from biological grease. The method comprises the following steps: 1, allowing hydrogen and raw oil which comprises one or more of biological grease to go through at least two hydrogenation reactors under hydrogenation operation conditions: allowing the raw oil and hydrogen to firstly go through a low temperature operation hydrogenation reactor and then go through a high temperature operation hydrogenation reactor, wherein the active component of a hydrogenation catalyst in a reaction state comprises one or several of W, Mo, Ni and Co; 2, separating a hydrogenation effluent into a gas phase which is circularly used and a liquid phase which enters a fractionating tower; and 3, supplying a sulfur-containing substance to reaction materials to maintain the content of hydrogen sulfide in the circulation gas. Compared with the prior art, the method of the invention can effectively improve the storage stability of the biological grease as fuel oil and also can effectively prolong the stability of a hydrogenation device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation method for producing high-quality kerosene

ActiveCN103374401AReduce the use effectSolve the problem of not being able to operate stably for a long period of timeTreatment with hydrotreatment processesIsomerizationNaphtha

The invention relates to a hydrogenation combination method for producing high-quality kerosene. The hydrogenation combination method comprises the steps that firstly, under the condition of hydrogenation, biolipid and recycle hydrogen are mixed and pass through a hydrotreating reaction zone, the gas obtained by separating a hydrotreating generated material flow is recycled, the liquid obtained by separation, the raw kerosene and the recycle hydrogen are mixed and pass through a hydrofining reaction zone and then enter a hydro-upgrading reaction zone at least comprising hydrogenation catalysts with isomerization performance, and the liquid obtained by separating a hydro-upgrading generated material flow is continuously fractionated, thus obtaining naphtha and high-quality kerosene products, wherein in the reaction state, the hydrogenation active components of the hydrogenation catalysts used in the hydrotreating reaction zone are one or more of W, Mo, Ni and Co in the reduction state. Compared with the prior art, the method has the advantages that not only can the storage stability of the biolipid as fuel oil be effectively improved but also the high-quality jet fuel product can be directly produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

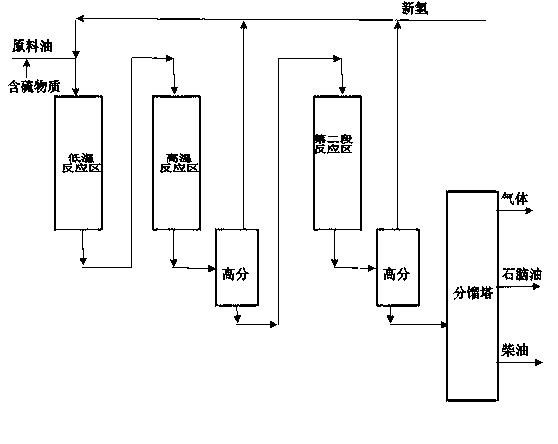

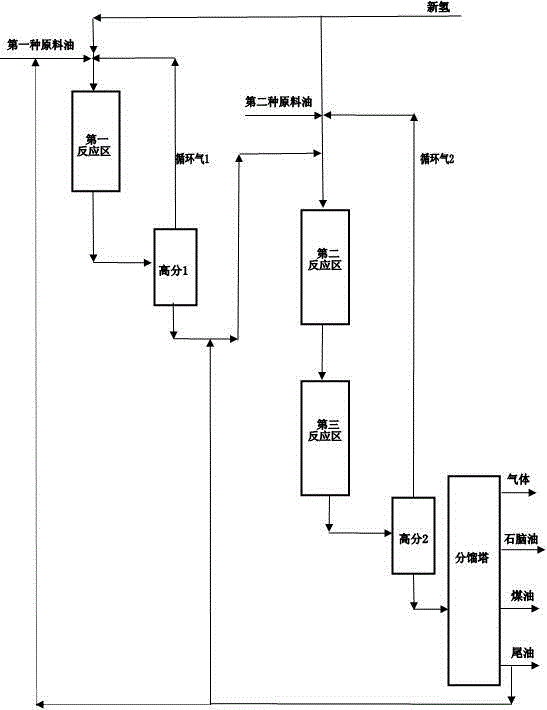

A hydrogenation combined method for producing high-quality low-condensation-point diesel oil from bio-oil

ActiveCN103374405BReduce the use effectSolve the problem of not being able to operate stably for a long period of timeTreatment with hydrotreatment processesOil and greaseIsomerization

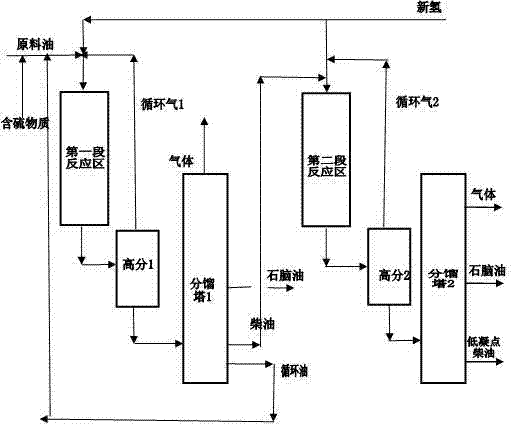

The invention relates to a hydrogenation combination method for producing high-quality low-condensation-point diesel oil. The hydrogenation combination method comprises the steps that firstly, under the condition of hydrogenation, biolipid and recycle hydrogen are mixed and pass through a hydrotreating reaction zone, the raw diesel oil and the recycle hydrogen are mixed and pass through a hydrofining reaction zone, the liquid obtained by separating a hydrotreating generated material flow and the liquid obtained by separating a hydrofining product are mixed and then enter a hydro-upgrading reaction zone at least comprising hydrogenation catalysts with isomerization performance, and the liquid obtained by separating a hydro-upgrading generated material flow is continuously fractionated, thus obtaining naphtha and high-quality low-condensation-point diesel oil products, wherein in the reaction state, the hydrogenation active components of the hydrogenation catalysts used in the hydrotreating reaction zone are one or more of W, Mo, Ni and Co in the sulfuration state. Compared with the prior art, the method has the advantages that not only can the storage stability of the biolipid as fuel oil be effectively improved but also the high-quality low-condensation-point clean diesel oil can be directly produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

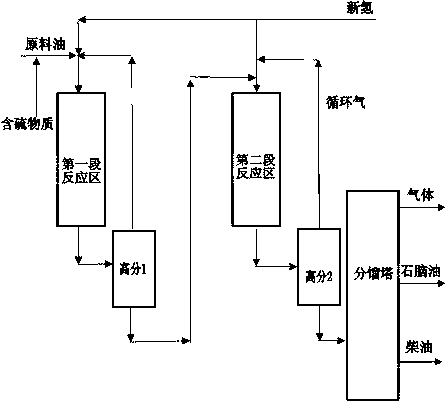

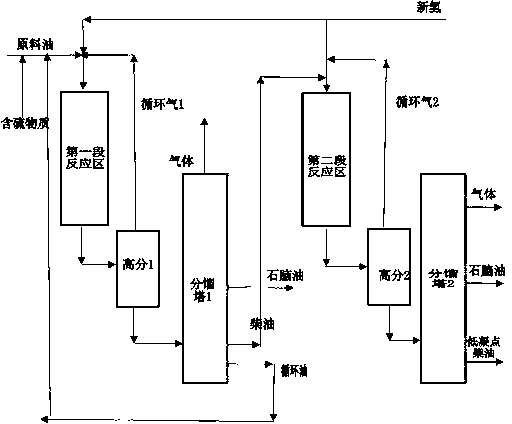

Two-stage hydrogenation method for producing low freezing point motor fuel

ActiveCN103102916ASolve the problem of not being able to operate stably for a long period of timeLowering the freezing pointLiquid hydrocarbon mixture productionBio-feedstockLiquid productOil and grease

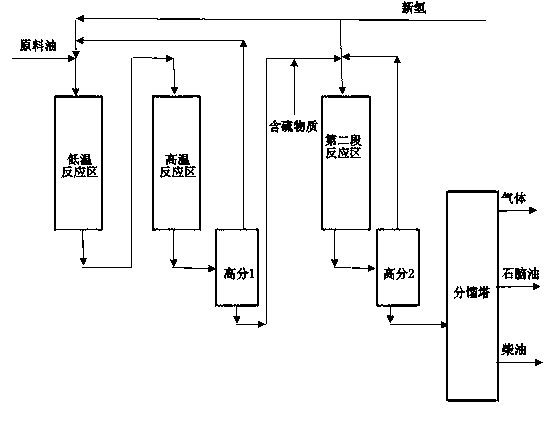

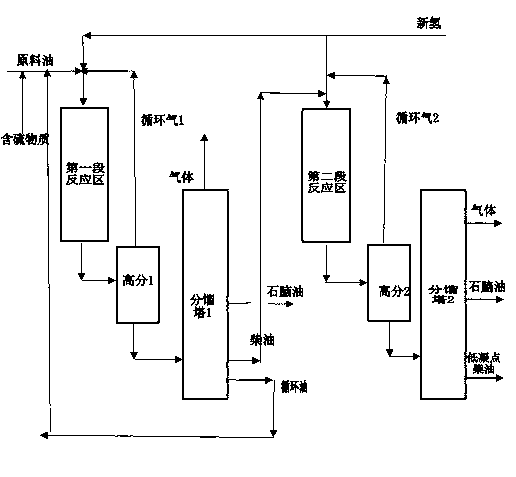

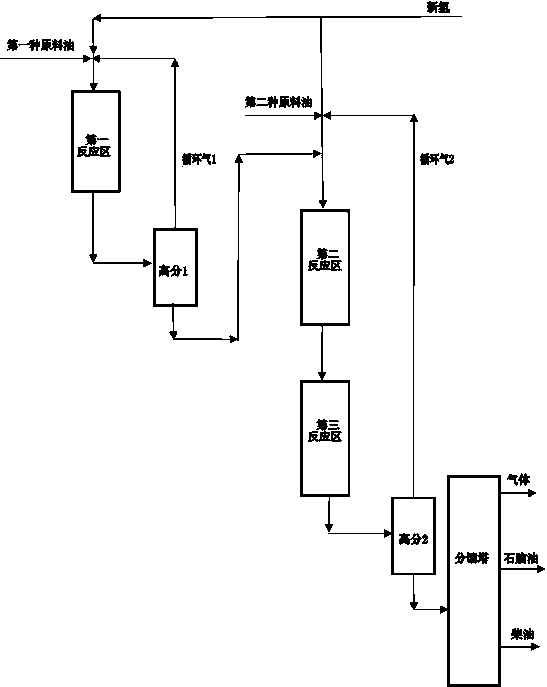

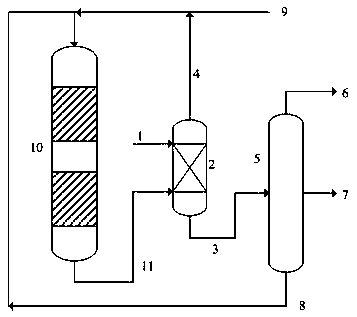

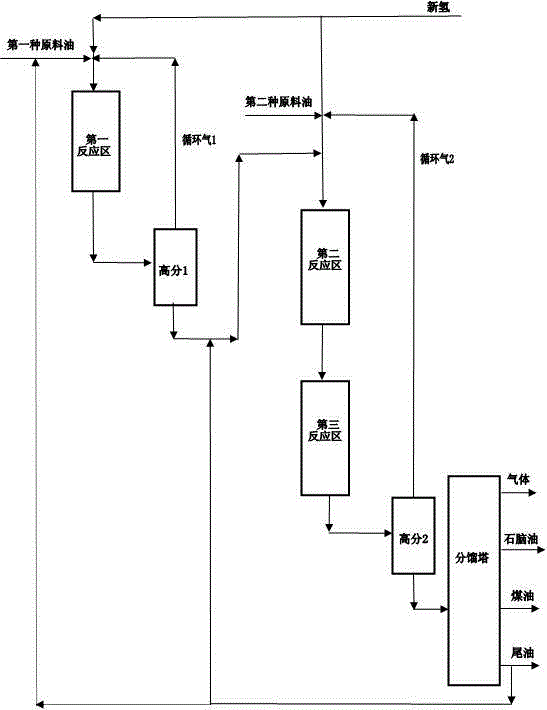

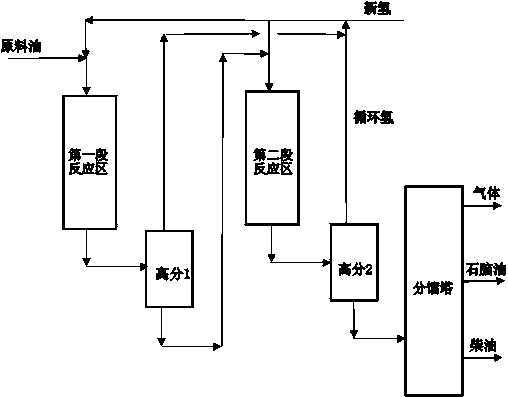

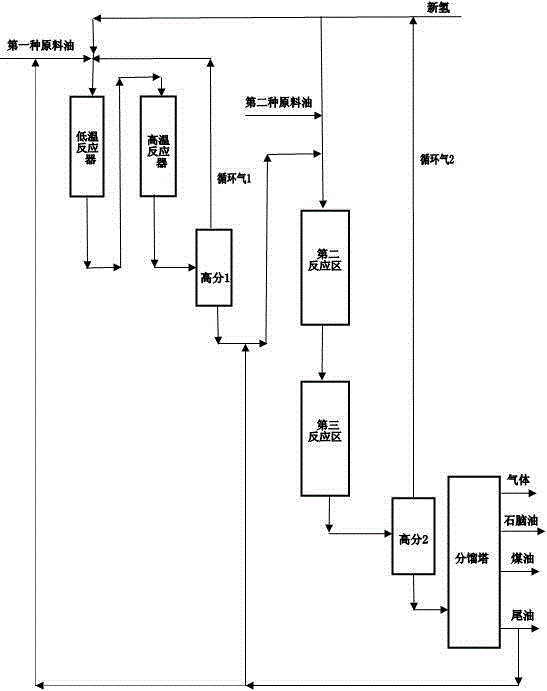

The present invention relates to a two-stage hydrogenation method for producing a low freezing point motor fuel. The method is characterized in that a biological oil is adopted as a raw material oil; under a hydrogenation condition, the raw material oil and hydrogen are mixed, and pass through a first stage hydrogenation reaction zone; the stream generated from hydrogenation is separated to obtain hydrogen-rich gas; the hydrogen-rich gas is recycled at the first stage; the separated liquid enters a second stage hydrogenation modification reaction zone; the sub-hydrogen gas separated from the oil generated through second stage hydrogenation is recycled at the second stage circulation; and the separated liquid product is subjected to fractionation to obtain naphtha and low freezing point diesel oil, wherein hydrogenation activity components of the hydrogenation catalyst used at the first stage are one or a plurality of materials selected from sulfurization state W, Mo, Ni and Co and hydrogenation activity components of the hydrogenation catalyst used at the second stage are one or a plurality of materials selected from reduction state W, Mo, Ni and Co under a reaction state. Compared to the method in the prior art, the two-stage hydrogenation method of the present invention has the following characteristics that: the low freezing point motor fuel can be produced, activity stability of the catalyst can be ensured, and stable and long period device operation can be ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation method for producing high-quality low-condensation-point diesel oil

ActiveCN103374398AReduce the use effectSolve the problem of not being able to operate stably for a long period of timeTreatment with hydrotreatment processesOil and greaseIsomerization

The invention relates to a hydrogenation method for producing high-quality low-condensation-point diesel oil. The hydrogenation method comprises the steps that firstly, under the condition of hydrogenation, biolipid and recycle hydrogen are mixed and pass through a hydrotreating reaction zone, the gas obtained by separating a hydrotreating generated material flow is recycled, the liquid obtained by separation, the raw diesel oil and the recycle hydrogen are mixed and pass through a hydrofining reaction zone and then enter a hydro-upgrading reaction zone at least comprising hydrogenation catalysts with isomerization performance, and the liquid obtained by separating a hydro-upgrading generated material flow is continuously fractionated, thus obtaining naphtha and low-condensation-point diesel oil products, wherein in the reaction state, the hydrogenation active components of the hydrogenation catalysts used in the hydrotreating reaction zone are one or more of W, Mo, Ni and Co in the sulfuration state. Compared with the prior art, the method has the advantages that not only can the storage stability of the biolipid as fuel oil be effectively improved but also the high-quality low-condensation-point clean diesel oil can be directly produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrotreating method for producing motor fuels with biological oil and fat

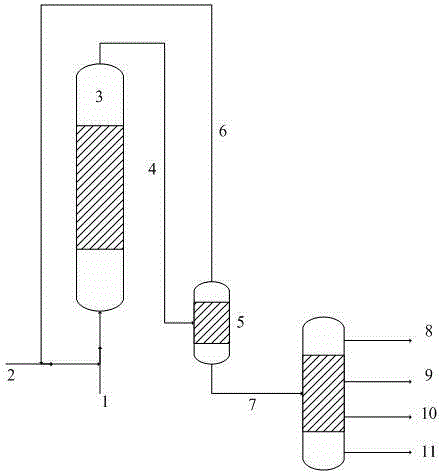

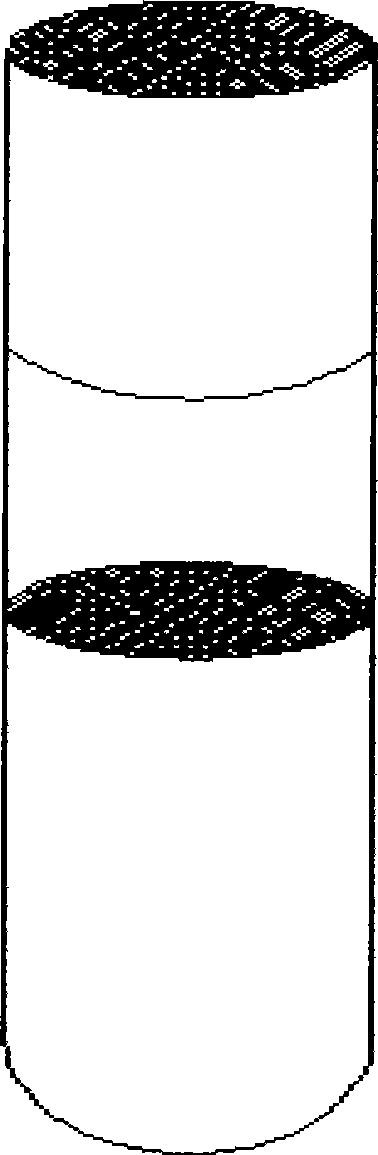

ActiveCN102911696BSmall pressure dropSolve the problem of not being able to operate stably for a long period of timeLiquid hydrocarbon mixture productionBio-feedstockOil and greaseNaphtha

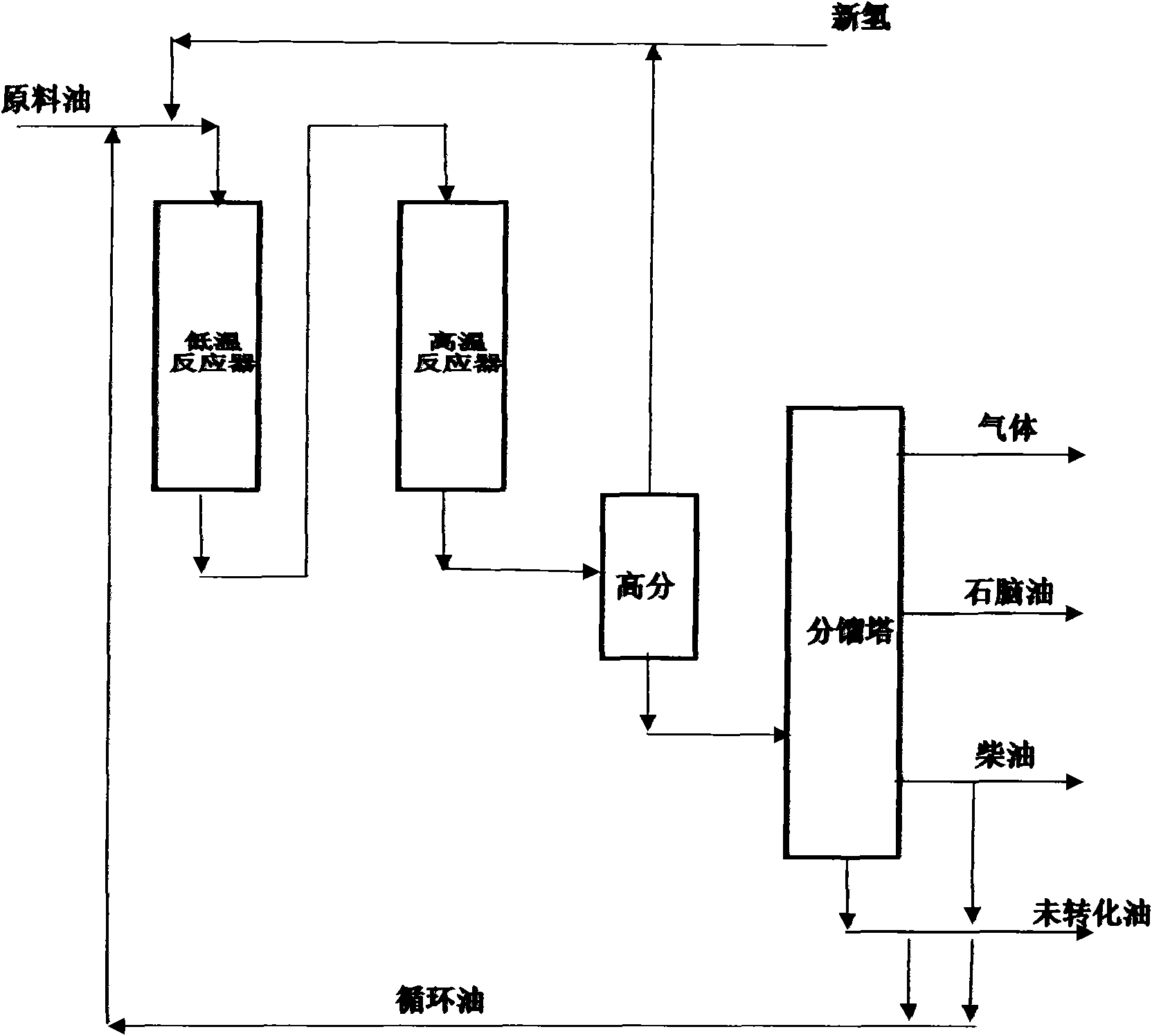

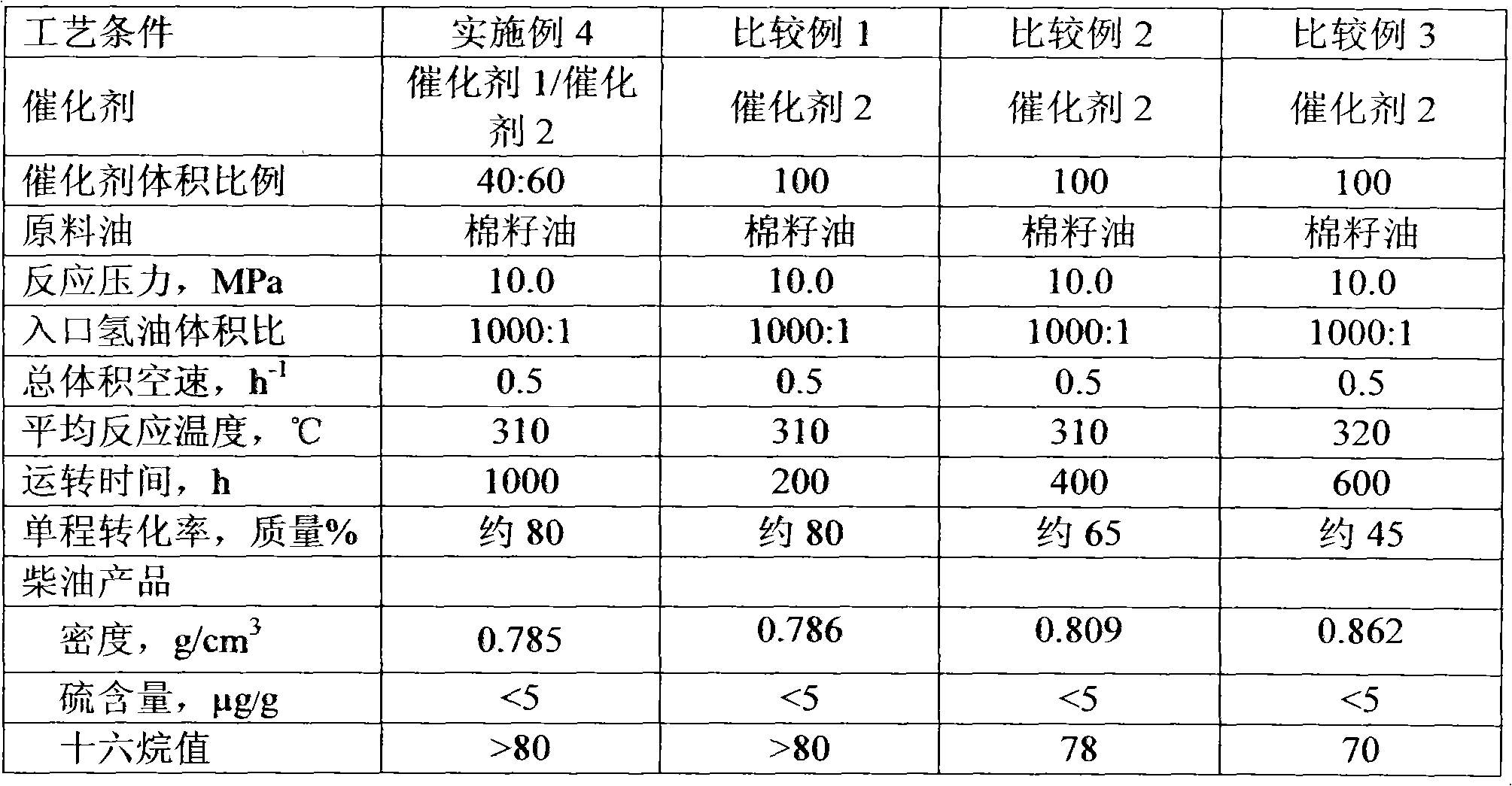

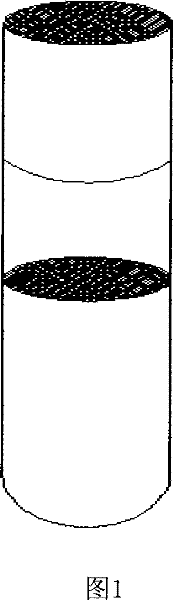

The invention discloses a hydrotreating method for producing motor fuels by hydrogenation of biological oil and fat. The method comprises the steps of (a) selecting one or more of the biological oil and fat as raw oil; (b) passing the raw oil and hydrogen successively through at least two reduced hydrogenation catalyst layers which has increased content of a hydrogenation active component in sequence, wherein the raw oil and hydrogen are introduced in from the bottom of the reactor, firstly passes through the reduced hydrogenation catalyst layer with low content of the hydrogenation active component, and then asses through the reduced hydrogenation catalyst layer with high content of the hydrogenation active component; (c) discharging effluent after the reaction from the top of the reactor, separating the effluent after the reaction into a gas phase and a liquid phase, wherein the gas phase is used circularly, and the liquid phase is introduced into a fractionating tower; and (d) fractionating in the fractionating tower to obtain naphtha, diesel oil and unconverted oil, wherein partial of the diesel oil and / or partial of the unconverted oil can be returned to the reaction system. The method provided by the invention can guarantee that a hydrogenation apparatus of the biological oil and fat runs stably in a long period.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation method for production of low-condensation point motor fuel from biolipid

ActiveCN103102897ASolve the problem of not being able to operate stably for a long period of timeLowering the freezing pointBiofuelsLiquid hydrocarbon mixture productionLiquid productOil and grease

The invention relates to a hydrogenation method for production of a low-condensation point motor fuel from biolipid. The method comprises the following steps that: biolipid is used as raw oil, and the raw oil and hydrogen pass through a first-stage hydrogenation reaction zone under hydrogenation operation conditions, wherein the first-stage hydrogenation reaction zone comprises at least two hydrogenation reactors, and the raw oil and hydrogen pass through one reactor operated at a low temperature at first and then pass through the other reactor operated at a high temperature; a material flow generated in hydrogenation is separated, obtained hydrogen-rich gas is recycled, and obtained liquid enters into a second-stage hydro-upgrading reaction zone; and a material flow generated in hydro-upgrading is separated, obtained side hydrogen is recycled, and an obtained liquid product is subjected to fractionation so as to obtain naphtha and low-condensation point diesel oil, wherein a sulfur-containing substance is supplemented to reaction materials so as to maintain the content of hydrogen sulfide in circulation gas. Compared with the prior art, the method provided by the invention can produce the low-condensation point motor fuel while guaranteeing activity stability of a catalyst and long-period stable running of an apparatus.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation method for producing high quality motor fuel by biolipid

InactiveCN102464992ASolve the problem of not being able to operate stably for a long period of timeHas industrial application valueBiofuelsLiquid hydrocarbon mixture productionChemistryFuel oil

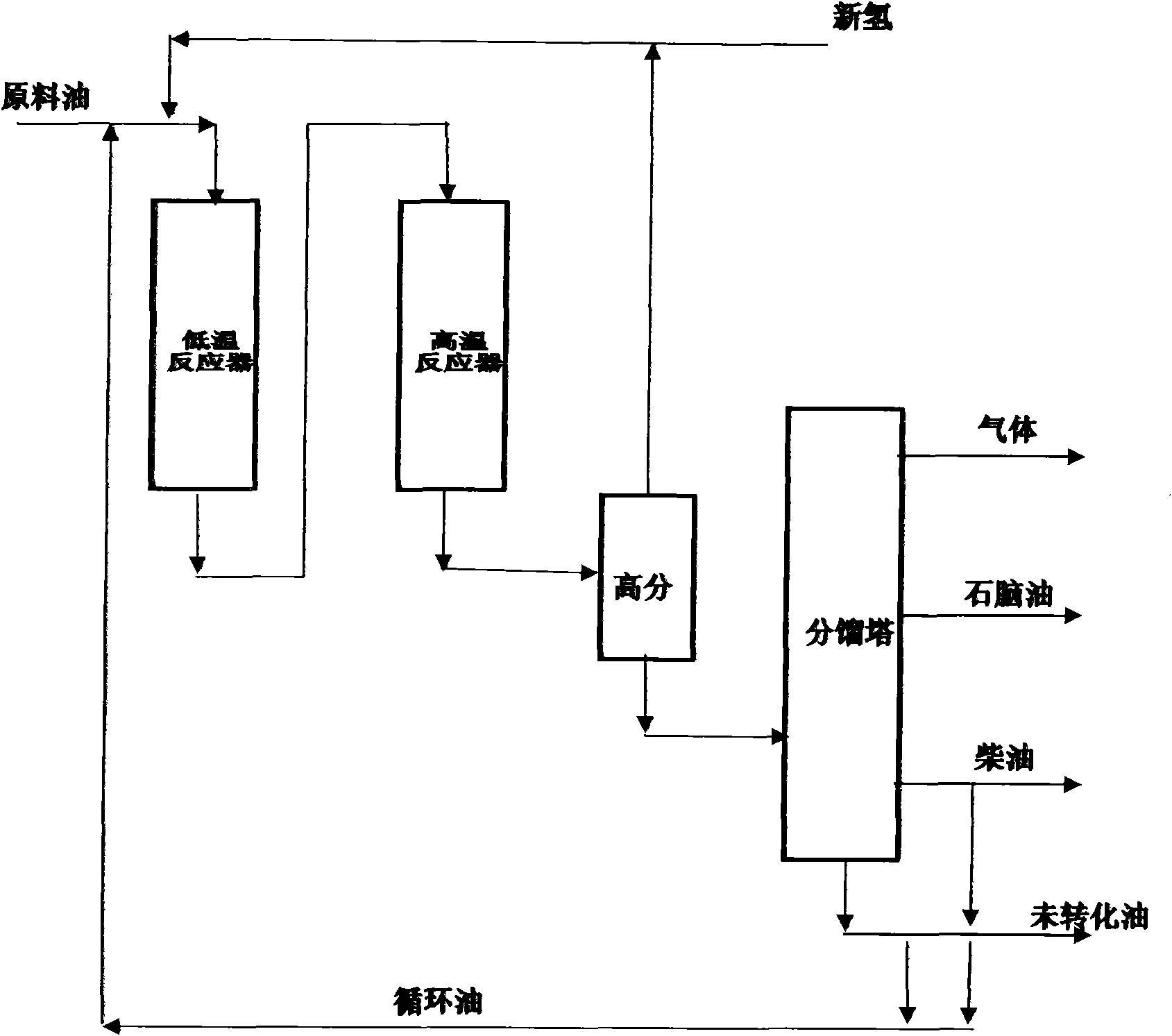

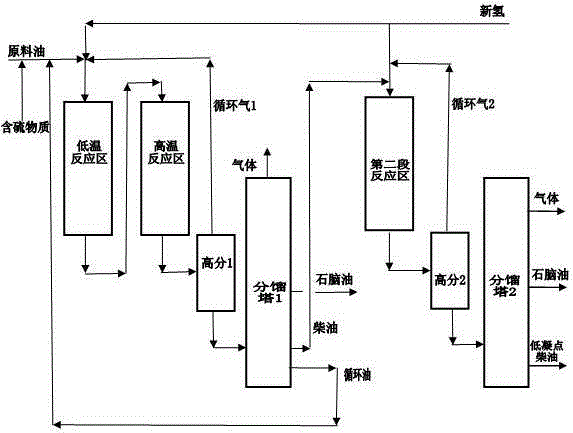

The present invention relates to a hydrogenation method for producing a high quality motor fuel by biolipid. The method comprises that: one or a plurality of materials in the biolipid are adopted as raw material oil; under a hydrogenation operating condition, the raw material oil and hydrogen gas pass through at least two hydrogenation reactors, wherein the raw material oil and the hydrogen gas firstly pass through the low temperature operation hydrogenation reactor, and then pass through the high temperature operation hydrogenation reactor; under the reaction state, the active component of a hydrogenation catalyst is reduced into the reduced-state Pt and / or the reduced-state Pd; the hydrogenated effluent is separated into a gas phase and a liquid phase, wherein the gas phase is recycled, and the liquid phase enters a fractionating tower; the liquid phase is fractionated in the fractionating tower to obtain naphtha, diesel oil and unconverted oil, wherein the partial diesel oil and / or the partial unconverted oil circularly returns to the reaction system. Compared to the prior art, with the method of the present invention, the storage stability of the biolipid can be effectively improved when the biolipid is adopted as the fuel oil, the stability of the hydrogenation device can be effectively prolonged, and the industrial application value of the biolipid hydrogenation technology can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Two-stage hydrogenation method for producing high quality low freezing point motor fuel from biological oil

ActiveCN103102905ASolve the problem of not being able to operate stably for a long period of timeLowering the freezing pointBiofuelsLiquid hydrocarbon mixture productionLiquid productOil and grease

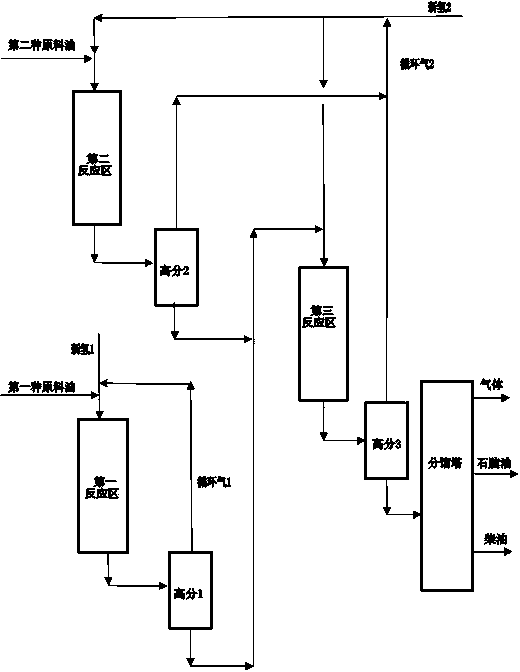

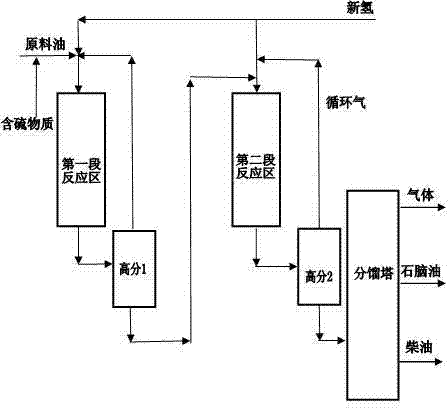

The invention relates to a two-stage hydrogenation method for producing a high quality low freezing point motor fuel from a biological oil. The method is characterized in that a biological oil raw material and hydrogen pass through a first stage hydrogenation reaction zone containing at least two hydrogenation reactors, wherein the mixture passes through a low temperature operation reactor, and then passes through a high temperature operation reactor; the hydrogen-rich gas is recycled at the first stage; the liquid enters a second stage hydrogenation modification reaction zone; the sub-hydrogen gas after hydrogenation modification is recycled at the second stage; the liquid product is subjected to fractionation to obtain naphtha and a low freezing point diesel oil; and under a reaction state, active components of the hydrogenation catalyst used at the first stage are reduction state Pt and / or Pd, and active components of the hydrogenation catalyst used at the second stage are one or a plurality of materials selected from sulfurization state W, Mo, Ni and Co. Compared to the method in the prior art, the method of the present invention has the following advantages that: a low freezing point motor fuel can be produced, activity stability of the catalyst can be ensured, and stable and long period device operation can be ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation combination method for producing high-quality diesel oil

ActiveCN103374404AReduce the use effectSolve the problem of not being able to operate stably for a long period of timeTreatment with hydrotreatment processesOil and greaseIsomerization

The invention relates to a hydrogenation combination method for producing high-quality diesel oil. The hydrogenation combination method comprises the steps that firstly, under the condition of hydrogenation, biolipid and recycle hydrogen are mixed and pass through a hydrotreating reaction zone, the raw diesel oil and the recycle hydrogen are mixed and pass through a hydrofining reaction zone, the liquid obtained by separating a hydrotreating generated material flow and the liquid obtained by separating a hydrofining product are mixed and then enter a hydro-upgrading reaction zone at least comprising hydrogenation catalysts with isomerization performance, and the liquid obtained by separating a hydro-upgrading generated material flow is continuously fractionated, thus obtaining naphtha and high-quality low-condensation-point diesel oil products, wherein in the reaction state, the hydrogenation active components of the hydrogenation catalysts used in the hydrotreating reaction zone are Pt and / or Pd in the reduction state. Compared with the prior art, the method has the advantages that not only can the storage stability of the biolipid as fuel oil be effectively improved but also the high-quality low-condensation-point clean diesel oil can be directly produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation method for producing motor fuel from biological oil

ActiveCN102464994ASolve the problem of not being able to operate stably for a long period of timeEasy to operateLiquid hydrocarbon mixture productionBio-feedstockOil and greaseGas phase

The invention relates to a hydrogenation method for producing motor fuel from biological oil. The hydrogenation method for producing motor fuel from biological oil is characterized in that at least one biological oil is utilized as raw oil; the raw oil and hydrogen orderly pass through a hydrotreatment reactor running at a low temperature and a hydrotreatment reactor running at a high temperature at least under hydrogenation operation conditions; under reaction conditions, active ingredients of a hydrotreatment catalyst comprise one or more of reduced W, Mo, Ni and Co; hydrogenated effluent is separated into a gas phase and a liquid phase; the gas phase is recycled and the liquid phase is fed into a fractionating tower; naphtha, diesel oil and unconverted oil are obtained in the fractionating tower; and a part of the diesel oil and / or a part of the unconverted oil are circulated to a reaction system. Compared with the prior art, the hydrogenation method for producing motor fuel from biological oil can effectively improve storage stability of biological oil as fuel oil and effectively prolong hydrogenation device stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Two-stage hydrogenation method for producing low freezing point motor fuel

ActiveCN103102917ALower freezing pointLowering the freezing pointBiofuelsLiquid hydrocarbon mixture productionNaphthaDiesel fuel

The present invention relates to a two-stage hydrogenation method for producing a low freezing point motor fuel. The method is characterized in that a biological oil raw material and hydrogen pass through a first stage hydrogenation reaction zone containing at least two hydrogenation reactors, wherein the mixture passes through a low temperature operation reactor, and then passes through a high temperature operation reactor; the hydrogen-rich gas is recycled at the first stage; the liquid enters a second stage hydrogenation modification reaction zone; the sub-hydrogen gas after hydrogenation modification is recycled at the second stage; the liquid product is subjected to fractionation to obtain naphtha and a low freezing point diesel oil; and under a reaction state, active components of the hydrogenation catalyst used at the first stage are one or a plurality of materials selected from sulfurization state W, Mo, Ni and Co, and active components of the hydrogenation catalyst used at the second stage are one or a plurality of materials selected from reduction state W, Mo, Ni and Co. Compared to the method in the prior art, the method of the present invention has the following advantages that: a low freezing point motor fuel can be produced, activity stability of the catalyst can be ensured, and stable and long period device operation can be ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

Two-stage hydrogenation method for producing high quality low freezing point motor fuel

ActiveCN103102912ASolve the problem of not being able to operate stably for a long period of timeLowering the freezing pointLiquid hydrocarbon mixture productionBio-feedstockOil and greaseLiquid product

The present invention relates to a two-stage hydrogenation method for producing a high quality low freezing point motor fuel. The method is characterized in that a biological oil is adopted as a raw material oil; under a hydrogenation condition, the raw material oil and hydrogen are mixed, and pass through a first stage hydrogenation reaction zone; the stream generated from hydrogenation is separated to obtain hydrogen-rich gas; the hydrogen-rich gas is recycled at the first stage; the separated liquid enters a second stage hydrogenation modification reaction zone; the sub-hydrogen gas separated from the oil generated through second stage hydrogenation is recycled at the second stage; and the separated liquid product is subjected to fractionation to obtain naphtha and a low freezing point diesel oil, wherein hydrogenation activity components of the hydrogenation catalyst used at the first stage are one or a plurality of materials selected from sulfurization state W, Mo, Ni and Co and hydrogenation activity components of the hydrogenation catalyst used at the second stage are reduction state Pt and / or Pd under a reaction state. Compared to the method in the prior art, the two-stage hydrogenation method of the present invention has the following characteristics that: the low freezing point motor fuel can be produced, activity stability of the catalyst can be ensured, and stable and long period device operation can be ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

Conversion method for hydrogenation of heavy and residual oil suspension bed

The invention discloses a conversion method of heavy and residual oil suspension bed hydrogenation. The method comprises the steps as follows: a feeding flow containing hydrogen and heavy and residual oil passes through a honeycomb-shaped or similar structure integrated reactor of a hydrogenation catalyst; the linear speed of liquid and gas in a hollow tower is controlled and a taylor flow is formed in the structural integrated reactor; and as the gas and the liquid are uniformly distributed in each passage, better gas-liquid distribution can be formed, the catalytic efficiency of the reactor can be greatly improved, and the running period can be effectively prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation method for production of low-condensation point motor fuel from biolipid

ActiveCN103102897BSolve the problem of not being able to operate stably for a long period of timeLowering the freezing pointBiofuelsLiquid hydrocarbon mixture productionLiquid productOil and grease

The invention relates to a hydrogenation method for production of a low-condensation point motor fuel from biolipid. The method comprises the following steps that: biolipid is used as raw oil, and the raw oil and hydrogen pass through a first-stage hydrogenation reaction zone under hydrogenation operation conditions, wherein the first-stage hydrogenation reaction zone comprises at least two hydrogenation reactors, and the raw oil and hydrogen pass through one reactor operated at a low temperature at first and then pass through the other reactor operated at a high temperature; a material flow generated in hydrogenation is separated, obtained hydrogen-rich gas is recycled, and obtained liquid enters into a second-stage hydro-upgrading reaction zone; and a material flow generated in hydro-upgrading is separated, obtained side hydrogen is recycled, and an obtained liquid product is subjected to fractionation so as to obtain naphtha and low-condensation point diesel oil, wherein a sulfur-containing substance is supplemented to reaction materials so as to maintain the content of hydrogen sulfide in circulation gas. Compared with the prior art, the method provided by the invention can produce the low-condensation point motor fuel while guaranteeing activity stability of a catalyst and long-period stable running of an apparatus.

Owner:CHINA PETROLEUM & CHEM CORP +1

Two-stage hydrogenation method for producing low freezing point motor fuel

ActiveCN103102917BLowering the freezing pointSolve the problem of not being able to operate stably for a long period of timeBiofuelsLiquid hydrocarbon mixture productionLiquid productOil and grease

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation method for producing high-quality diesel oil

ActiveCN103374406AReduce the use effectSolve the problem of not being able to operate stably for a long period of timeTreatment with hydrotreatment processesOil and greaseIsomerization

The invention relates to a hydrogenation method for producing high-quality diesel oil. The hydrogenation method comprises the steps that firstly, under the condition of hydrogenation, biolipid and recycle hydrogen are mixed and pass through a hydrotreating reaction zone, the gas obtained by separating a hydrotreating generated material flow is recycled, the liquid obtained by separation, the raw diesel oil and the recycle hydrogen are mixed and pass through a hydrofining reaction zone and then enter a hydro-upgrading reaction zone at least comprising hydrogenation catalysts with isomerization performance, and the liquid obtained by separating a hydro-upgrading generated material flow is continuously fractionated, thus obtaining naphtha and low-condensation-point diesel oil products, wherein in the reaction state, the hydrogenation active components of the hydrogenation catalysts used in the hydrotreating reaction zone are Pt and / or Pd in the reduction state. Compared with the prior art, the method has the advantages that not only can the storage stability of the biolipid as fuel oil be effectively improved but also the high-quality low-condensation-point clean diesel oil can be directly produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for hydrodeoxygenation of biological oil

PendingCN111100703AEasy to separateImprove responseTreatment with hydrotreatment processesHydrocarbon oils treatment productsOil and greasePtru catalyst

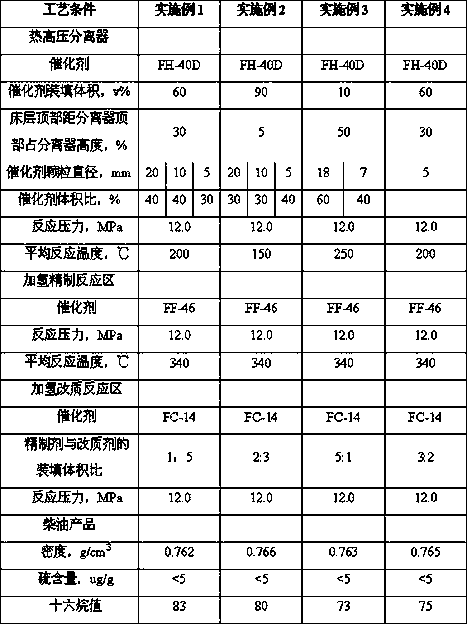

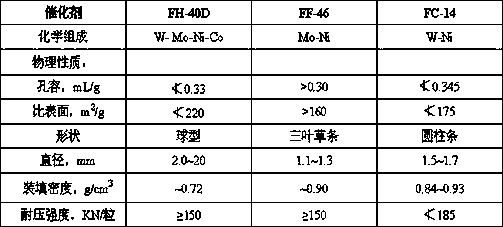

The invention discloses a method for hydrodeoxygenation of biological oil. The method comprises the following steps: (1) the biological oil enters a thermal high-pressure separator to be in contact with a catalyst 1 filled in the thermal high-pressure separator to perform olefin saturation and shallow hydrodeoxygenation reaction; (2) a gas-phase effluent at the top of the thermal high-pressure separator can be recycled as supplementary hydrogen, a liquid-phase effluent enters a fractionating tower, and gasoline, diesel oil and unconverted oil are obtained through separation; and (3) the unconverted oil enters a hydrofining reactor to be subjected to a deep hydrodeoxygenation reaction under the action of a catalyst 2, and an effluent enters the thermal high-pressure separator. The method can ensure the activity stability of the catalyst and the long-period stable operation of the device while producing the low-condensation-point diesel oil blending component, and has the advantages of low production cost and simple operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Vegetable oil hydro-upgrading method

PendingCN111100704AResolve separabilityAddress reactivityTreatment with hydrotreatment processesHydrocarbon oils treatment productsOil and greaseVegetable oil

The invention discloses a method for hydrodeoxygenation of vegetable oil. The method comprises the following steps: (1) biological oil enters a thermal high-pressure separator to be in contact with acatalyst 1 filled in the thermal high-pressure separator to perform olefin saturation and shallow hydrodeoxygenation reaction; (2) a gas-phase effluent at the top of the thermal high-pressure separator can be recycled as supplementary hydrogen, a liquid-phase effluent enters a fractionating tower, and gasoline, diesel oil and unconverted oil are obtained through separation; and (3) the unconvertedoil and hydrogen are mixed to enter a hydro-upgrading reactor to carry out deep hydrodeoxygenation reaction and isomery pour point depression, and an effluent enters the thermal high-pressure separator. The method can ensure the activity stability of the catalyst and the long-period stable operation of the device while producing the low-condensation-point diesel oil blending component, and has the advantages of low production cost and simple operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

A hydrogenation method for producing high-quality kerosene

ActiveCN103374401BReduce the use effectSolve the problem of not being able to operate stably for a long period of timeTreatment with hydrotreatment processesIsomerizationNaphtha

The invention relates to a hydrogenation combination method for producing high-quality kerosene. The hydrogenation combination method comprises the steps that firstly, under the condition of hydrogenation, biolipid and recycle hydrogen are mixed and pass through a hydrotreating reaction zone, the gas obtained by separating a hydrotreating generated material flow is recycled, the liquid obtained by separation, the raw kerosene and the recycle hydrogen are mixed and pass through a hydrofining reaction zone and then enter a hydro-upgrading reaction zone at least comprising hydrogenation catalysts with isomerization performance, and the liquid obtained by separating a hydro-upgrading generated material flow is continuously fractionated, thus obtaining naphtha and high-quality kerosene products, wherein in the reaction state, the hydrogenation active components of the hydrogenation catalysts used in the hydrotreating reaction zone are one or more of W, Mo, Ni and Co in the reduction state. Compared with the prior art, the method has the advantages that not only can the storage stability of the biolipid as fuel oil be effectively improved but also the high-quality jet fuel product can be directly produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Two-stage hydrogenation method for producing low freezing point motor fuel from biological oil

ActiveCN103102910BSolve the problem of not being able to operate stably for a long period of timeLowering the freezing pointLiquid hydrocarbon mixture productionBio-feedstockOil and greaseLiquid product

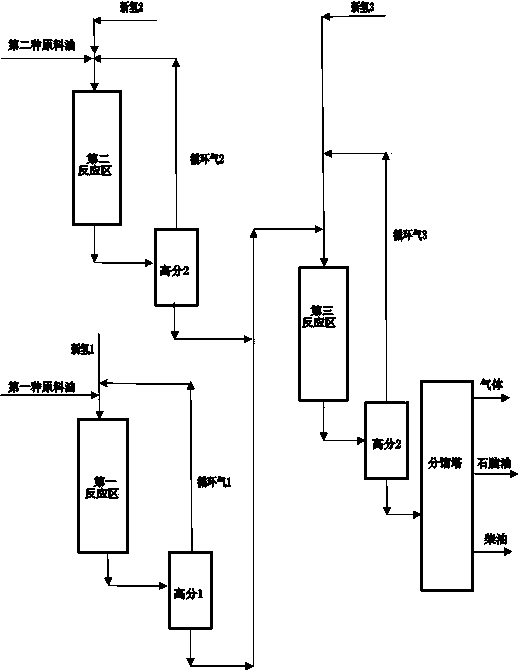

The present invention relates to a two-stage hydrogenation method for producing a low freezing point motor fuel from a biological oil. The method is characterized in that a biological oil is adopted as a raw material oil; under a hydrogenation condition, the raw material oil and hydrogen are mixed, and pass through a first stage hydrogenation reaction zone; hydrogen-rich gas separated from a stream generated through hydrogenation is recycled at the first stage; the separated liquid enters a second stage hydrogenation modification reaction zone; and sub-hydrogen gas separated from the oil generated through second stage hydrogenation is recycled at the second stage, and the separated liquid product is subjected to fractionation to obtain naphtha and a low freezing point motor fuel, wherein hydrogenation activity components of the hydrogenation catalyst used at the first stage are one or a plurality of materials selected from reduction state W, Mo, Ni and Co, and hydrogenation activity components of the hydrogenation catalyst used at the second stage are one or a plurality of materials selected from sulfurization state W, Mo, Ni and Co under a reaction state. Compared with the method in the prior art, the method of the present invention has the following advantages that: a low freezing point motor fuel can be produced, activity stability of the catalyst can be ensured, and stable and long period device operation can be ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

Combination method for producing high-quality kerosene through hydrogenation

ActiveCN103374412BReduce the use effectSolve the problem of not being able to operate stably for a long period of timeTreatment with hydrotreatment processesIsomerizationKerosene

The invention relates to a combination method for producing high-quality kerosene through hydrogenation. The combination method comprises the steps that firstly, under the condition of hydrogenation, biolipid and recycle hydrogen are mixed and pass through a hydrotreating reaction zone, the gas obtained by separating a hydrotreating generated material flow is recycled, the liquid obtained by separation, raw kerosene and the recycle hydrogen are mixed and pass through a hydrofining reaction zone and then enter a hydro-upgrading reaction zone at least comprising hydrogenation catalysts with isomerization performance, and the liquid obtained by separating a hydro-upgrading generated material flow is continuously fractionated, thus obtaining naphtha and high-quality kerosene products, wherein in the reaction state, the hydrogenation active components of the hydrogenation catalysts used in the hydrotreating reaction zone are Pt and / or Pd in the reduction state. Compared with the prior art, the method has the advantages that not only can the storage stability of the biolipid as fuel oil be effectively improved but also high-quality jet fuel products can be directly produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation method for producing high quality low freezing point motor fuel from biological oil

ActiveCN103102925BSolve the problem of not being able to operate stably for a long period of timeLowering the freezing pointLiquid hydrocarbon mixture productionBio-feedstockOil and greaseLiquid product

The present invention relates to a hydrogenation method for producing a high quality low freezing point motor fuel from a biological oil. The method is characterized in that a biological oil is adopted as a raw material oil; under a hydrogenation operation condition, the raw material oil and hydrogen gas pass through a first stage hydrogenation reaction zone containing at least two hydrogenation reactors, wherein the raw material oil and the hydrogen gas sequentially pass through a low temperature operation reactor and a high temperature operation reactor; hydrogen-rich gas separated from the stream generated from hydrogenation is recycled, and the separated liquid enters a second stage hydrogenation modification reaction zone; sub-hydrogen gas separated from the stream generated from hydrogenation modification is recycled, and the separated liquid product is subjected to fractionation to obtain naphtha and a low freezing point diesel oil; and under a reaction state, active components of the hydrogenation catalysts used at the first stage and the second stage are sulfurization state Pt and / or Pd. Compared to the method in the prior art, the method of the present invention has the following advantages that: storage stability can be effectively improved when the biological oil is adopted as a fuel oil, and hydrogenation device stability can be effectively prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydro-upgrading method for production of low-condensation point motor fuel from biolipid

ActiveCN103102896BSolve the problem of not being able to operate stably for a long period of timeLowering the freezing pointBiofuelsLiquid hydrocarbon mixture productionOil and greaseLiquid product

The invention relates to a hydro-upgrading method for production of a low-condensation point motor fuel from biolipid. The method comprises the following steps that: biolipid is used as raw oil, and the raw oil and hydrogen pass through a first-stage hydrogenation reaction zone, wherein the first-stage hydrogenation reaction zone comprises at least two hydrogenation catalyst beds in which the content of a hydrogenation active component successively increases; a material flow generated in first-stage hydrogenation is separated, obtained hydrogen-rich gas is recycled, and obtained liquid enters into a second-stage hydro-upgrading reaction zone; and a material flow generated in second-stage hydrogenation is separated, obtained side hydrogen is recycled, and an obtained liquid product is subjected to fractionation so as to obtain naphtha and low-condensation point diesel oil; wherein in a reaction state, the active component of all the hydrogenation catalysts is one or more selected from the group consisting of W, Mo, Ni and Co in a reduction state. Compared with the prior art, the method provided by the invention can produce the low-condensation point motor fuel while guaranteeing activity stability of the catalysts and long-period stable running of an apparatus.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation combined method for producing high-quality kerosene

ActiveCN103374409BReduce the use effectSolve the problem of not being able to operate stably for a long period of timeTreatment with hydrotreatment processesIsomerizationNaphtha

The invention relates to a hydrogenation combination method for producing high-quality kerosene. The hydrogenation combination method comprises the steps that firstly, under the condition of hydrogenation, biolipid and recycle hydrogen are mixed and pass through a hydrotreating reaction zone, the gas obtained by separating a hydrotreating generated material flow is recycled, the liquid obtained by separation, the raw kerosene and the recycle hydrogen are mixed and pass through a hydrofining reaction zone and then enter a hydro-upgrading reaction zone at least comprising hydrogenation catalysts with isomerization performance, and the liquid obtained by separating a hydro-upgrading generated material flow is continuously fractionated, thus obtaining naphtha and kerosene products, wherein in the reaction state, the hydrogenation active components of the hydrogenation catalysts used in the hydrotreating reaction zone are one or more of W, Mo, Ni and Co in the sulfuration state. Compared with the prior art, the method has the advantages that not only can the storage stability of the biolipid as fuel oil be effectively improved but also the high-quality kerosene can be directly produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Two-stage hydrogenation method for producing low freezing point motor fuel

ActiveCN103102916BSolve the problem of not being able to operate stably for a long period of timeLowering the freezing pointLiquid hydrocarbon mixture productionBio-feedstockOil and greaseLiquid product

The present invention relates to a two-stage hydrogenation method for producing a low freezing point motor fuel. The method is characterized in that a biological oil is adopted as a raw material oil; under a hydrogenation condition, the raw material oil and hydrogen are mixed, and pass through a first stage hydrogenation reaction zone; the stream generated from hydrogenation is separated to obtain hydrogen-rich gas; the hydrogen-rich gas is recycled at the first stage; the separated liquid enters a second stage hydrogenation modification reaction zone; the sub-hydrogen gas separated from the oil generated through second stage hydrogenation is recycled at the second stage circulation; and the separated liquid product is subjected to fractionation to obtain naphtha and low freezing point diesel oil, wherein hydrogenation activity components of the hydrogenation catalyst used at the first stage are one or a plurality of materials selected from sulfurization state W, Mo, Ni and Co and hydrogenation activity components of the hydrogenation catalyst used at the second stage are one or a plurality of materials selected from reduction state W, Mo, Ni and Co under a reaction state. Compared to the method in the prior art, the two-stage hydrogenation method of the present invention has the following characteristics that: the low freezing point motor fuel can be produced, activity stability of the catalyst can be ensured, and stable and long period device operation can be ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

A hydrogenation method for producing high-quality motor fuel from bio-oil

ActiveCN102464993BSolve the problem of not being able to operate stably for a long period of timeBiofuelsLiquid hydrocarbon mixture productionOil and greaseGas phase

The invention relates to a hydrogenation method for producing a high-quality motor fuel with biological grease. The method comprises: taking one or several kinds of biological grease as raw oil; passing the raw oil and hydrogen through at least two precious metal hydrogenation catalyst beds, the hydrogenation active component contents of which increase in order, leaving the raw oil and hydrogen first to pass through a catalyst bed with low hydrogenation active component content and then to pass through a catalyst bed with high hydrogenation active component content, with reduced Pt and / or Pd adopted as the hydrogenation active component under a reaction state; separating a hydrogenation effluent into a gas phase and a liquid phase, recycling the gas phase and leaving the liquid phase to enter a fractionating tower; conducting fractionation in the fractionating tower so as to obtain naphtha, diesel oil and unconverted oil, circulating part of the diesel oil and / or part of the unconverted oil back to a reaction system. Compared with prior art, the method of the invention not only can effectively improve the storage stability of biological grease taken as fuel oil, and simultaneously can realize long-period stable operation of a device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Conversion method for hydrogenation of heavy and residual oil suspension bed

The invention discloses a conversion method of heavy and residual oil suspension bed hydrogenation. The method comprises the steps as follows: a feeding flow containing hydrogen and heavy and residual oil passes through a honeycomb-shaped or similar structure integrated reactor of a hydrogenation catalyst; the linear speed of liquid and gas in a hollow tower is controlled and a taylor flow is formed in the structural integrated reactor; and as the gas and the liquid are uniformly distributed in each passage, better gas-liquid distribution can be formed, the catalytic efficiency of the reactorcan be greatly improved, and the running period can be effectively prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation method for producing low freezing point motor fuel from biological oil

ActiveCN103102924BSolve the problem of not being able to operate stably for a long period of timeLowering the freezing pointLiquid hydrocarbon mixture productionBio-feedstockLiquid productOil and grease

The present invention relates to a hydrogenation method for producing a low freezing point motor fuel from a biological oil. The method is characterized in that a biological oil is adopted as a raw material oil; under a hydrogenation condition, the raw material oil and hydrogen are mixed, and pass through a first stage hydrogenation reaction zone; hydrogen-rich gas separated from a stream generated through hydrogenation is recycled; the separated liquid enters a second stage hydrogenation modification reaction zone; and sub-hydrogen gas separated from the oil generated through second stage hydrogenation is recycled, and the separated liquid product is subjected to fractionation to obtain naphtha and a low freezing point motor fuel. Compared with the method in the prior art, the method of the present invention has the following advantages that: a low freezing point motor fuel can be produced, activity stability of the catalyst can be ensured, and stable and long period device operation can be ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com