Hydrogenation method for producing motor fuel from biological grease

A technology for bio-oil and motor fuel, which is used in the preparation of biological raw materials, liquid hydrocarbon mixtures, and the petroleum industry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

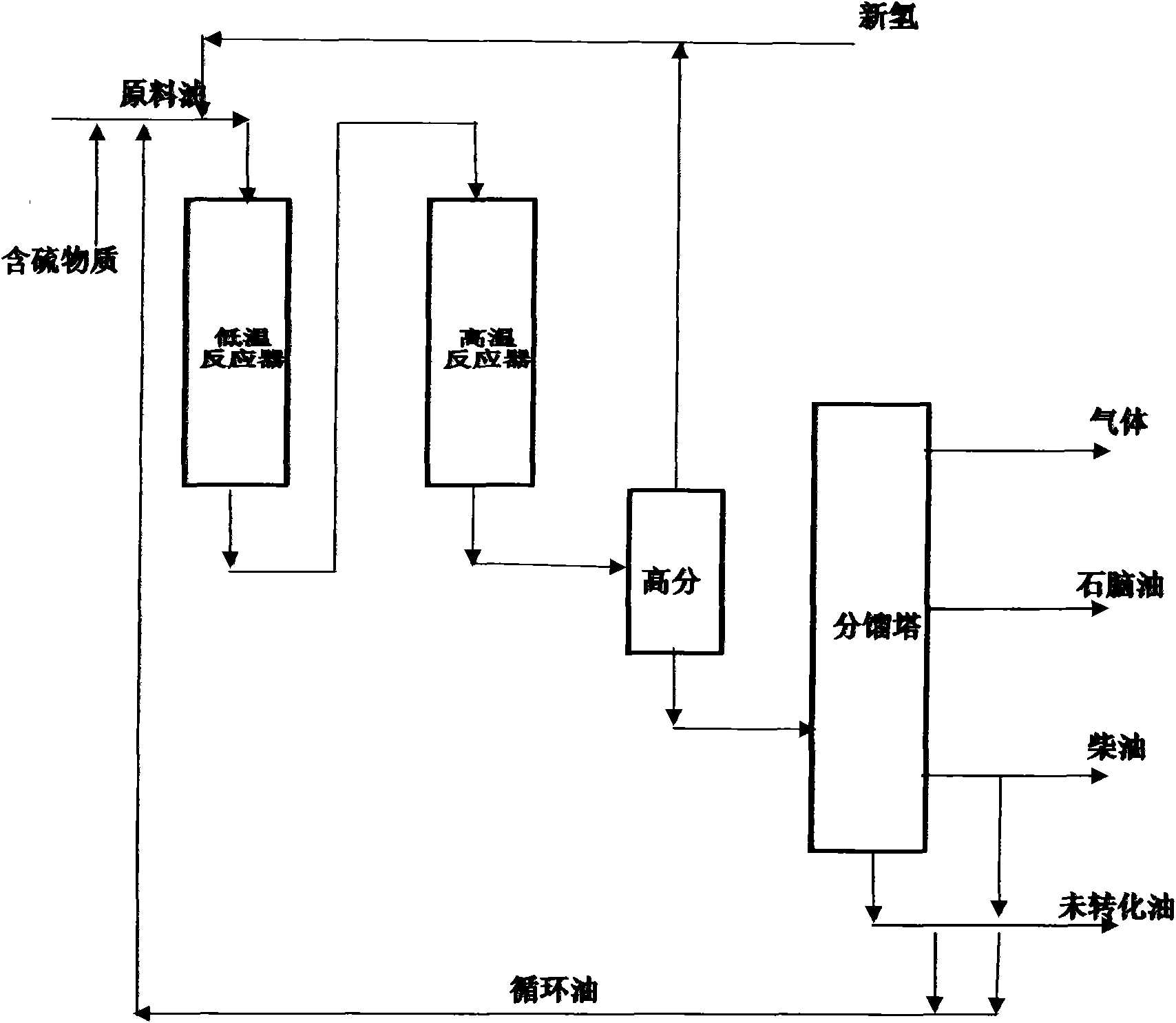

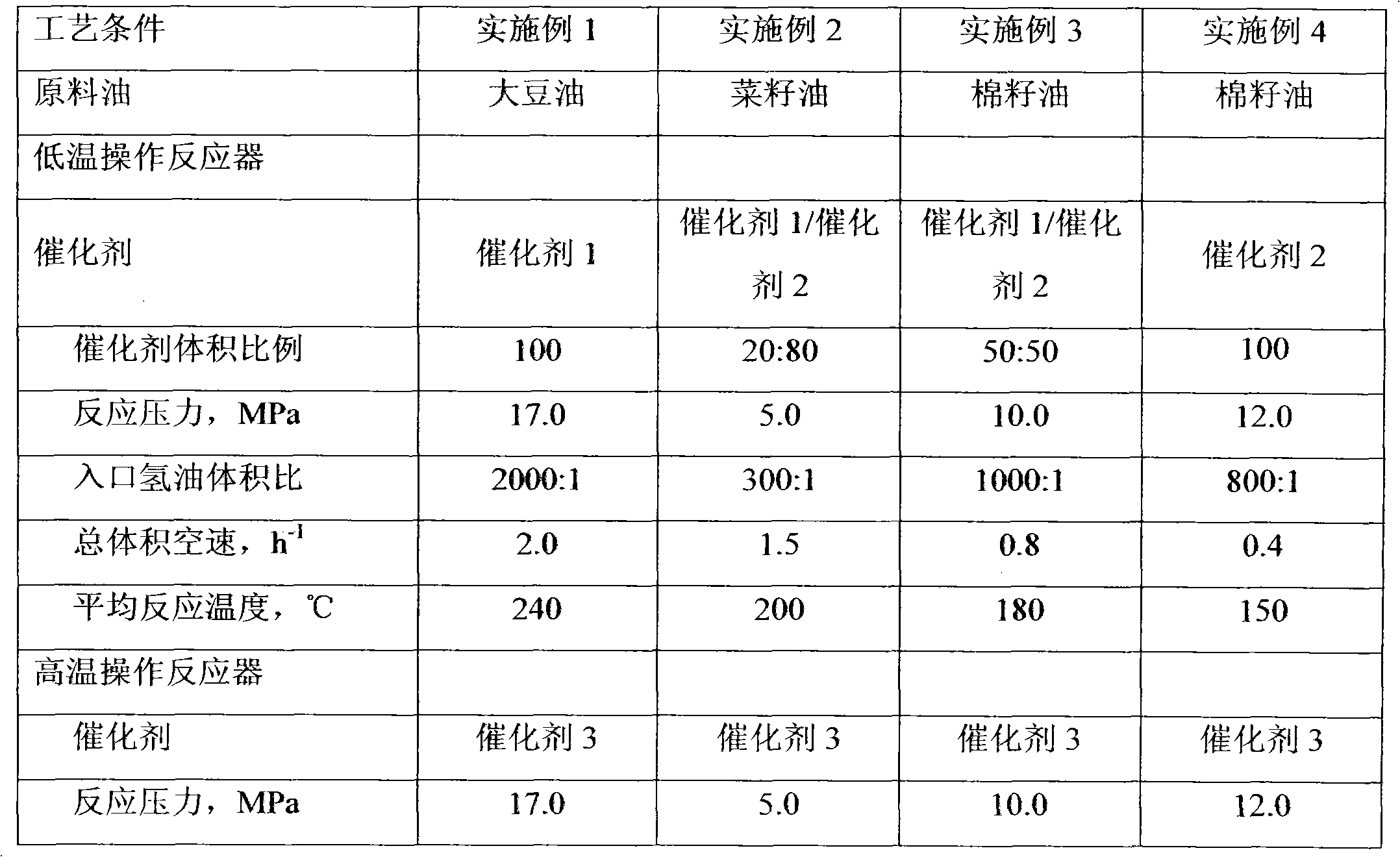

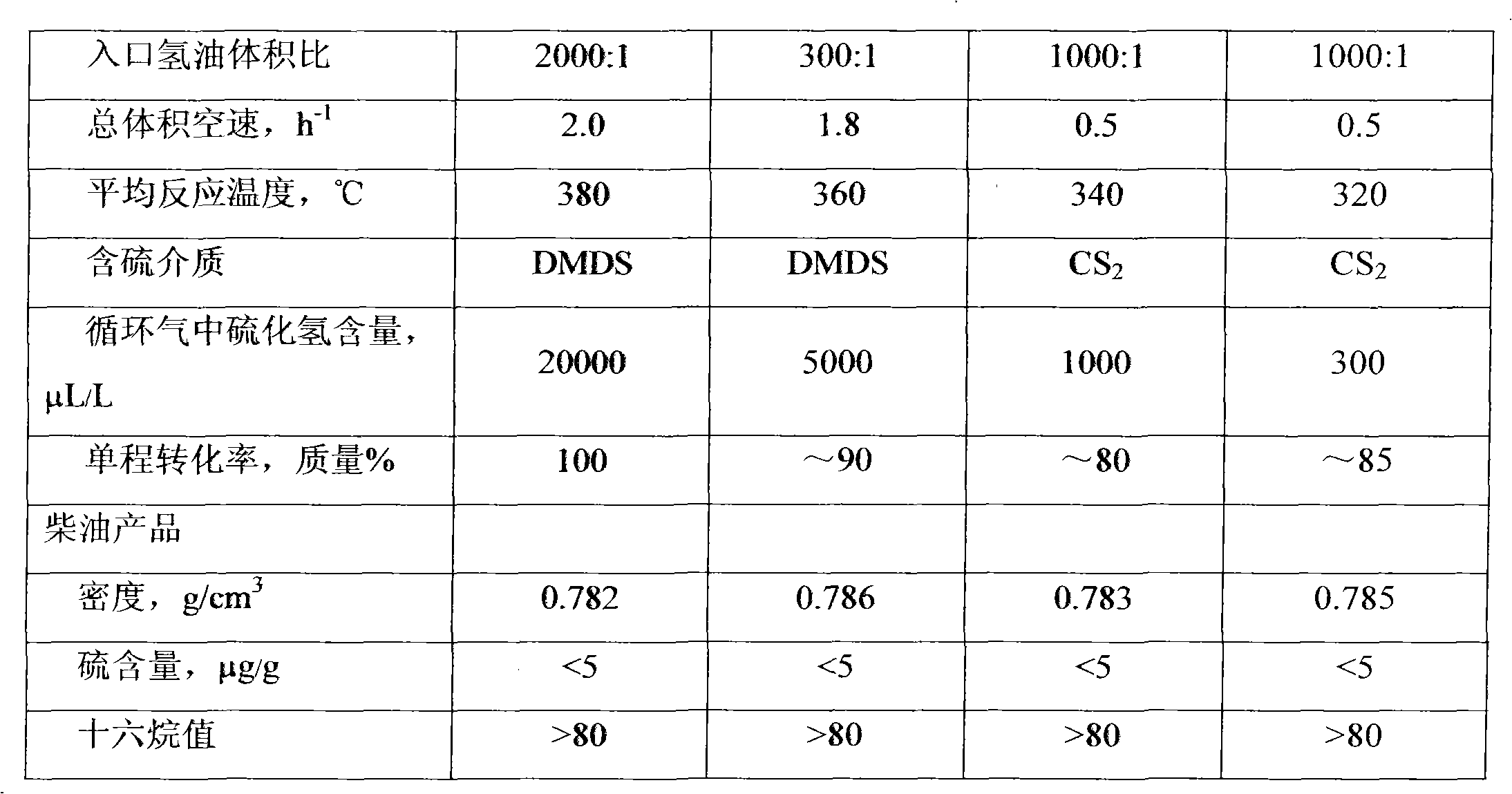

[0023] The method of the present invention is specifically as follows: using one or several mixed oils in the bio-grease as the raw material oil, under the hydrogenation operation condition, the raw material oil and hydrogen pass through the low-temperature and high-temperature hydrogenation reactors filled with catalysts, and the obtained hydrogenated The hydrogen-generated oil is recycled in the gas separated by the high-pressure separator (abbreviated as high fraction), and can also be discharged from the system, and the obtained liquid is fractionated to obtain the following products: one or more of gas, naphtha, and diesel oil. Depending on the nature of the diesel product or to extend the operating cycle, a portion of the diesel and unconverted oil is also considered to be recycled back to the reaction system. The bio-oil used in the examples is a commercially available product, and solid impurities are filtered out before use.

[0024] Further illustrate the specific si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com