Aqueous cleaning agent composition and cleaning agent for printed circuit board and its preparation method and application

A technology for printed circuit boards and water-based cleaning agents, applied in the direction of non-surface active detergent compositions, detergent compositions, organic non-surface active detergent compositions, etc., which can solve the problems of fast volatilization, huge ozone layer destruction, and high VOC emissions. problems, to achieve the effect of safe and reliable use, avoiding silicon residue problems, and no VOC emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

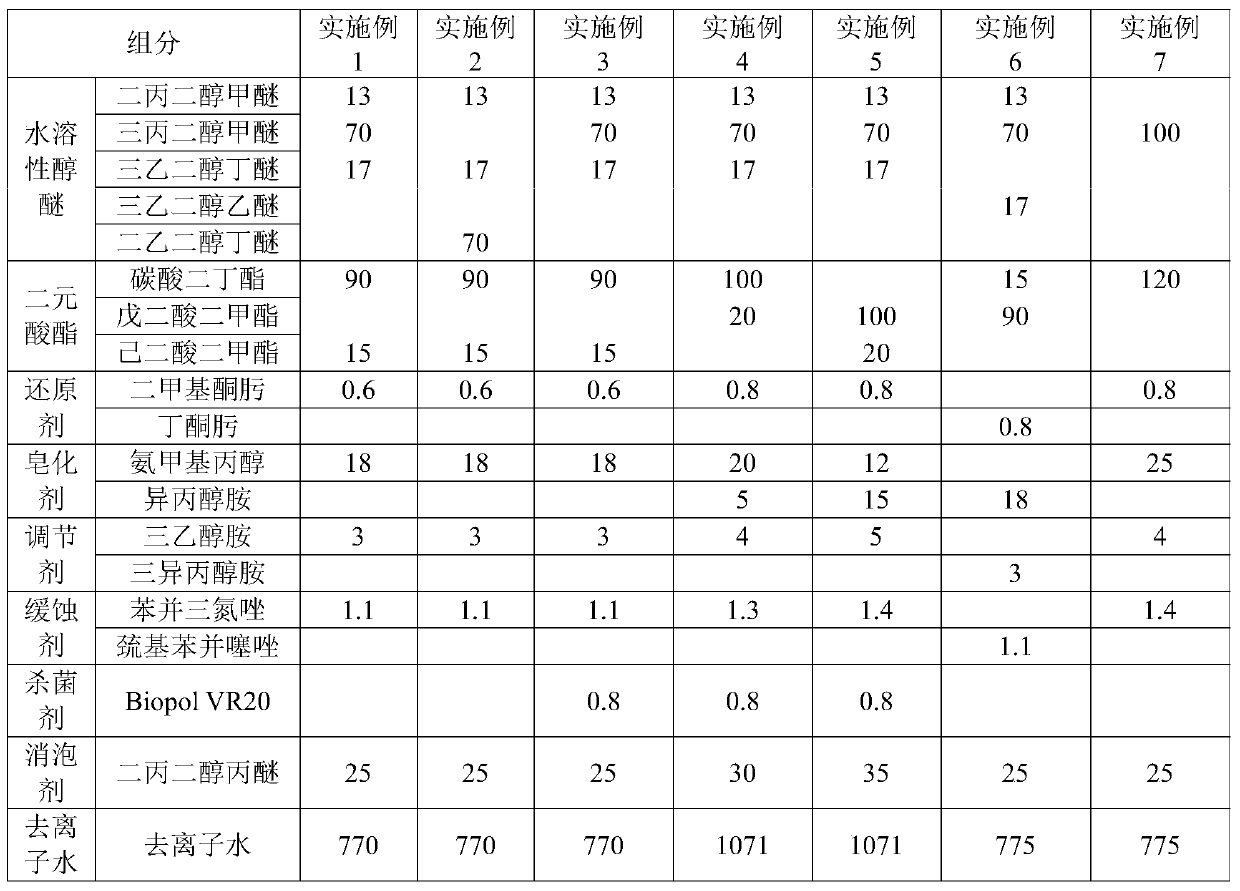

[0050] Cleaning agents A1-A7 were prepared according to the composition formulation in Table 1 below. Its preparation method specifically is: dissolving the nonionic organic reducing agent (abbreviated as reducing agent in Table 1) in deionized water (wherein the concentration of the nonionic organic reducing agent is 25% by weight), stirring evenly; then, deionized Put the components other than water into the stirring tank, stir at high speed for 20 minutes, then add the remaining deionized water and stir for 5 minutes.

[0051] Table 1

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com