System for preparing butanol and its application

A butanol and fermenter technology, which is applied in the field of butanol preparation system, can solve the problems of fermentation system, low butanol recovery rate, environmental pollution, etc., to reduce the possibility of bacterial contamination and recover butanol The effect of high efficiency and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

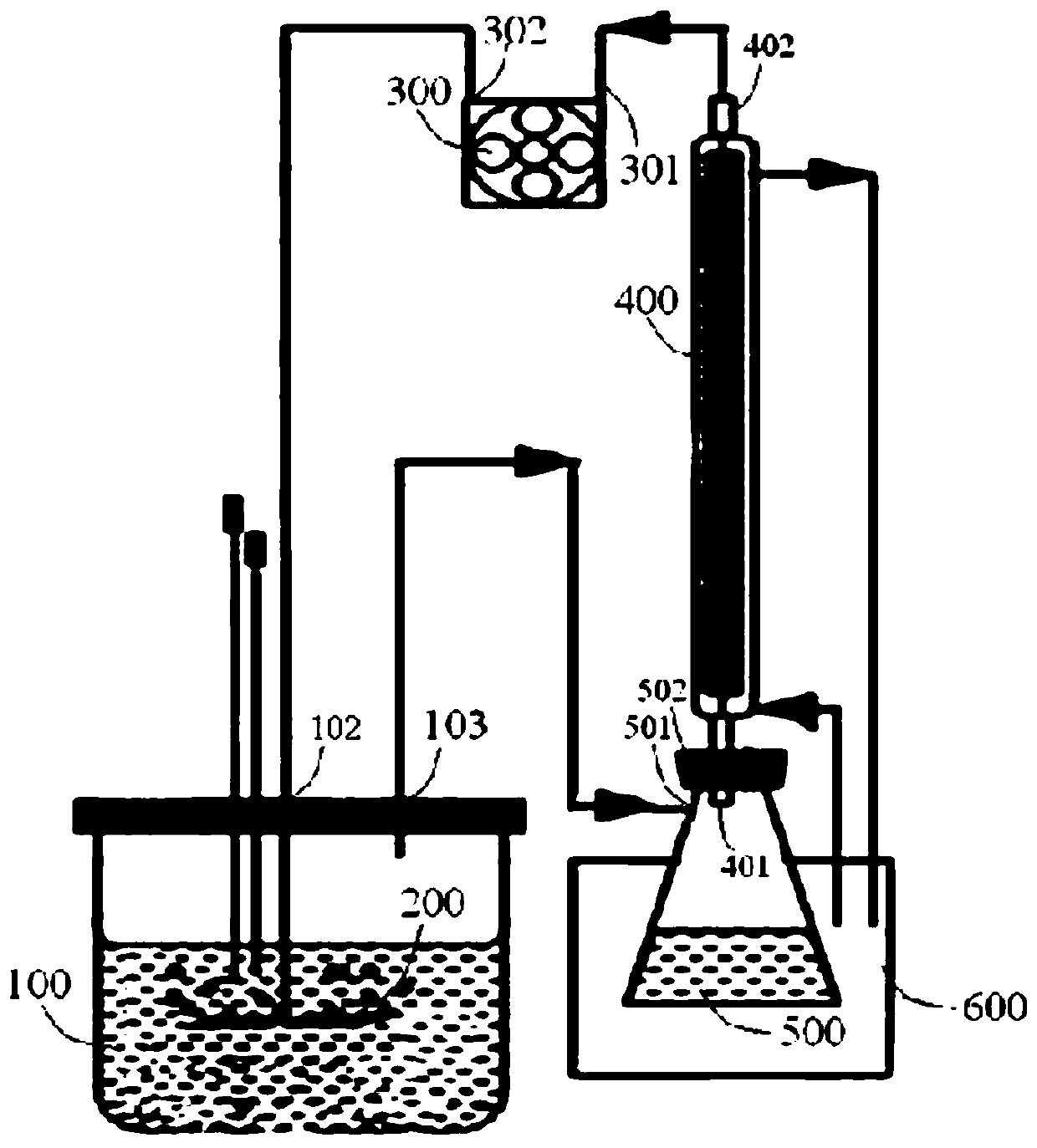

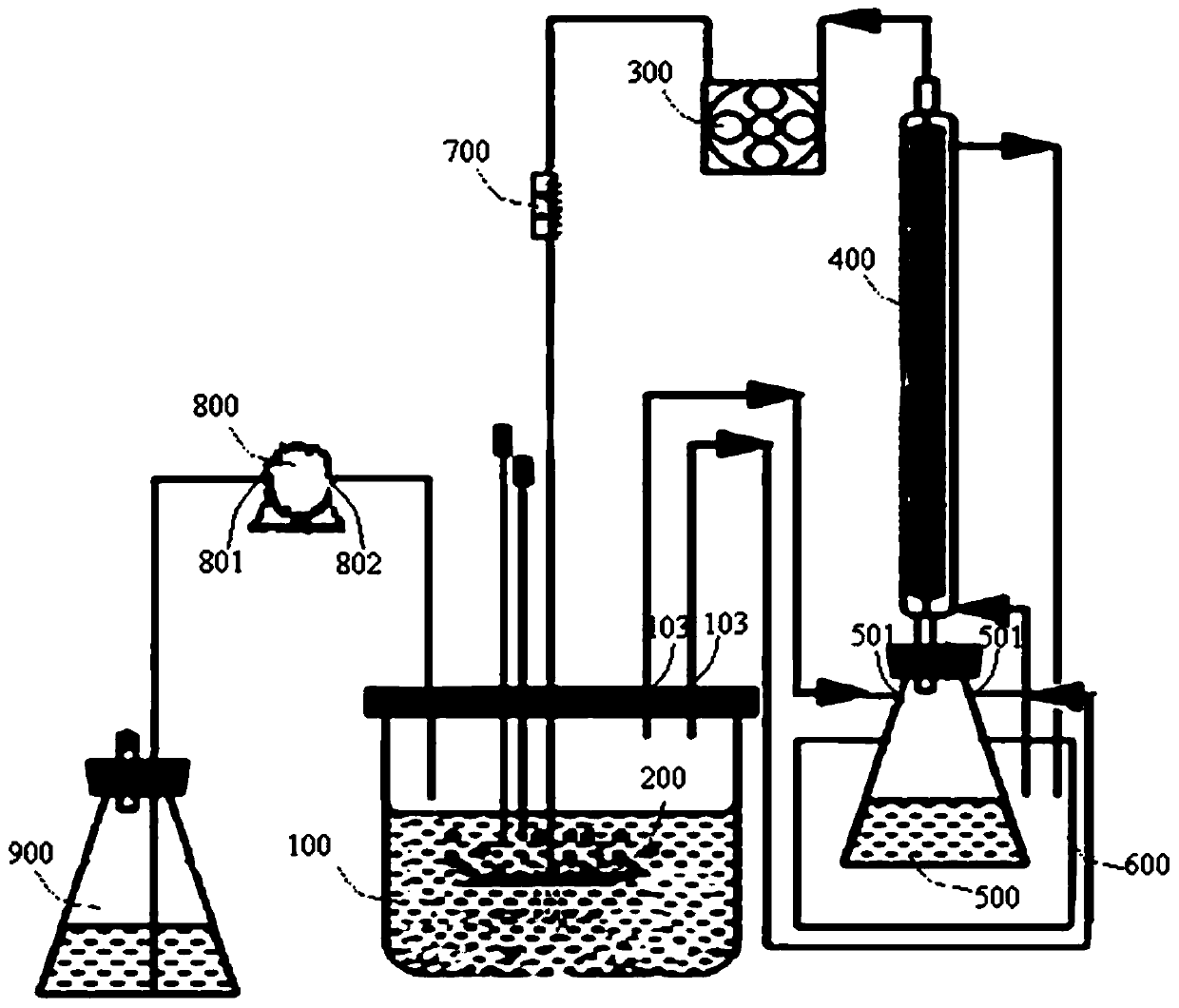

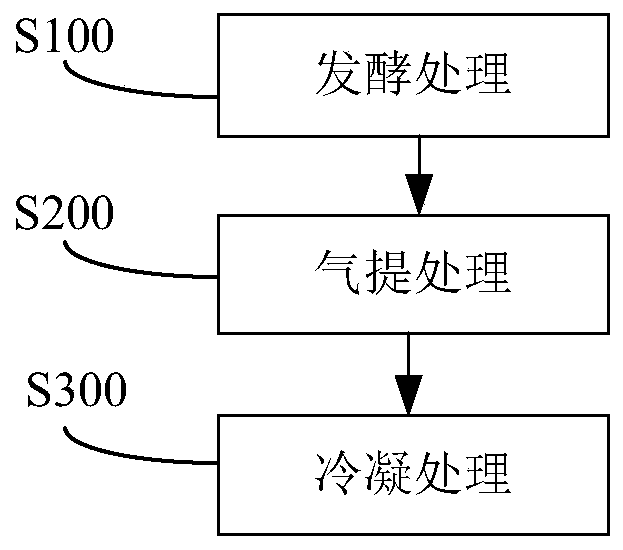

[0046] According to the system for preparing butanol according to the embodiment of the present invention, symbiotic bacteria are used for fermentation to produce butanol under non-strict anaerobic conditions, and the self-produced gas of the fermentation generates bubbles in the fermentation liquid through a gas distributor, and the bubbles intercept butanol, and then It is condensed and recovered in the condenser, and the condensed self-produced gas is re-introduced into the gas distributor through the gas circulation pump for recycling, so as to realize the self-produced gas cycle stripping, and the self-gas is used for stripping, the condensation effect is good, and the gas tail gas is avoided The generation of ABE in the middle, the environmental pollution is little. At the same time, the structure of the system is simple, and the fermenter is also an air stripping tank, so that the butanol production and butanol extraction process are carried out in the same bioreactor, a...

Embodiment 1

[0071] In this example, butanol was produced by gas stripping by using batch fermentation coupled with batch cycle self-produced gas, and the butanol-producing bacteria were cultivated and fermented according to the general method for producing butanol. When the butanol concentration in the fermenter is close to 7g / L, start the gas circulation pump and the low-temperature circulating water bath, and the condensation temperature is -5°C. The gas produced by the butanol-producing symbiotic bacteria system during the fermentation process turns into bubbles and enters through the gas distributor. In the fermenter, as a stripping gas. Air stripping treatment adopts intermittent air stripping method. Start gas stripping when the butanol concentration in the fermentation broth is greater than 7g / L, and stop the gas stripping when the butanol concentration in the fermentation broth is lower than 6g / L. The gas flow rate is 1-4vvm. The results are shown in Table 1.

Embodiment 2

[0073] In this example, butanol was prepared by gas stripping by fed-batch fermentation coupled with batch cycle self-produced gas, and the butanol-producing bacteria were cultivated and fermented according to the general method for preparing butanol. When the butanol concentration in the fermenter is close to 7g / L, start the gas circulation pump and the low-temperature circulating water bath, and the condensation temperature is -5°C. The gas produced by the butanol-producing symbiotic bacteria system during the fermentation process turns into bubbles and enters through the gas distributor. In the fermenter, as a stripping gas. The air stripping method adopts the intermittent air stripping method. Start gas stripping when the butanol concentration in the fermentation broth is greater than 7g / L, and stop the gas stripping when the butanol concentration in the fermentation broth is lower than 6g / L. The gas flow rate is 1-4vvm. When the glucose concentration is close to 10g / L, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com