Diesel engine tail gas filter

A technology of exhaust filter and diesel engine, which is applied in the direction of machines/engines, exhaust devices, mechanical equipment, etc. It can solve the problems of a large amount of black smoke, inability to effectively filter soot particles, and low emissions, so as to eliminate acidic components and improve The effect of exhaust gas purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

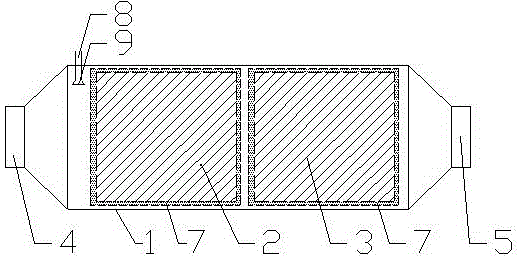

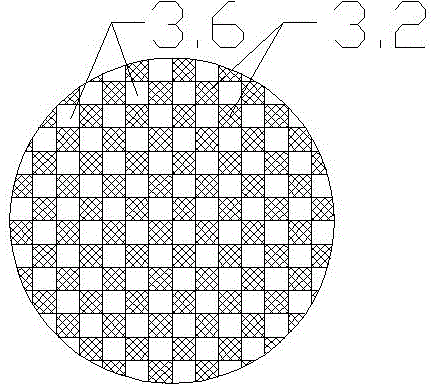

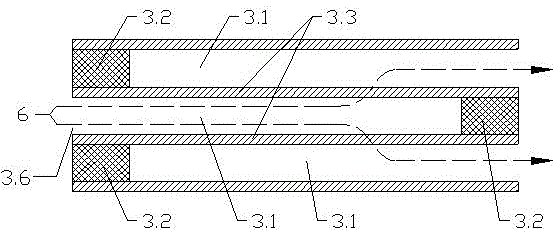

[0032] see Figure 1-4 , the present invention relates to a diesel engine exhaust filter, which includes a filter box 1, an oxidation catalyst 2 and a ceramic honeycomb carrier 3, the left end of the filter box 1 is an exhaust gas inlet 4, and the right end is an exhaust gas outlet 5, the oxidation catalyst 2 and the ceramic honeycomb carrier 3 are arranged in the filter box 1, the ceramic honeycomb carrier 3 is close to the tail gas inlet 4, and the oxidation catalyst 2 is close to the tail gas outlet 5, the filter box 1 is in the shape of a circular tube, and the ceramic honeycomb carrier 3 Corresponding to the inner wall of the filter box 1, and the ceramic honeycomb carrier 3 is densely covered with air holes 3.1 along the axial direction, one end of the air holes 3.1 is an opening 3.6, and the other end is provided with a sealing surface 3.2, the sealing surface 3.2 and the opening 3.6 Arranged at intervals, the two adjacent air holes 3.1 are provided with a partition wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com