Hydraulic motor driving variable compression ratio piston

A hydraulic motor, driven technology, applied in the direction of piston, engine components, engine control, etc., can solve the problems of complex mechanism structure, poor manufacturability, and high research and development cost, and achieve the effect of simple mechanism structure, low manufacturing cost, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] specific implementation plan

[0047] The present invention is described in detail below in conjunction with accompanying drawing:

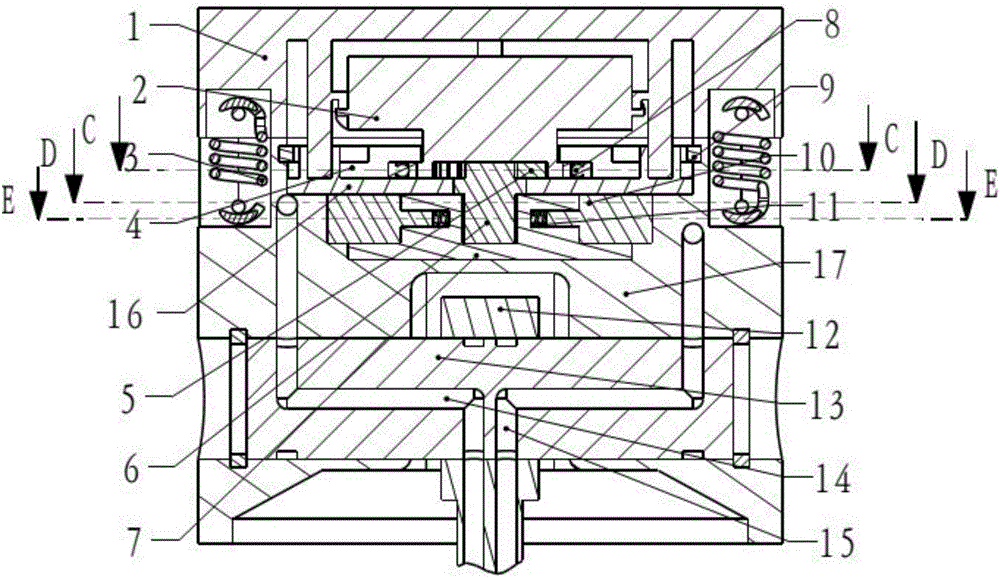

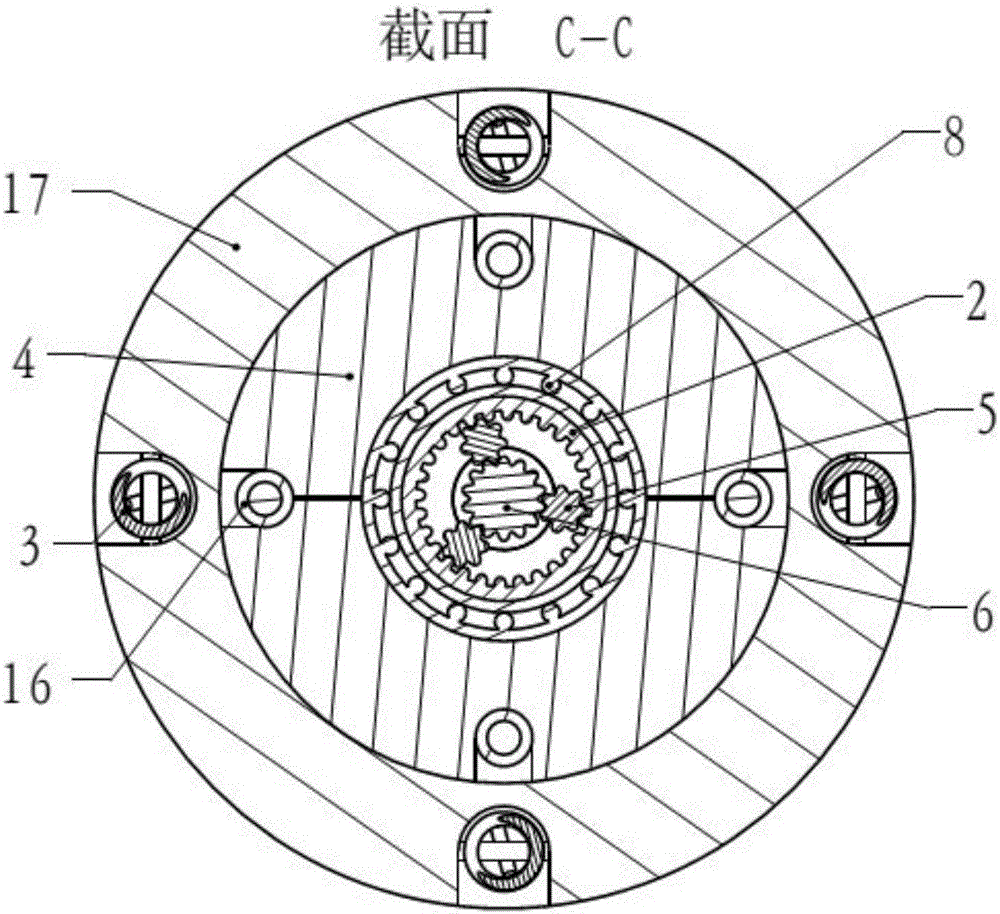

[0048] refer to figure 1 and figure 2 , the piston is divided into two parts: the top of the piston 1 and the skirt 10 of the piston along the section. A hydraulic motor and a runner 3 are installed in the cavity formed by the two parts. Two oil passages are drilled in the skirt 10 of the piston. The hydraulic motor provides an inlet and outlet oil passage, and there are connecting rods in four circular holes on the outer wall of the piston top 1 for fastening the connection of the spring 2 .

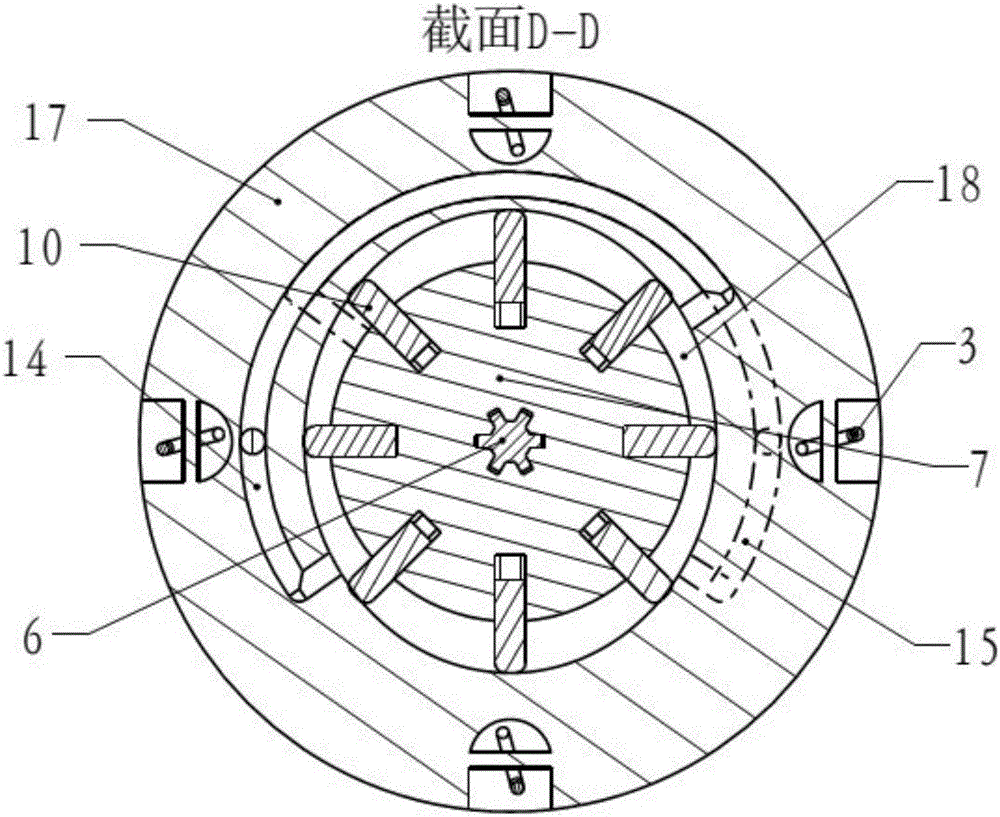

[0049] refer to Figure 8 and Figure 9 , the center of the top section of the piston is a large cavity, and four columnar rods are evenly distributed around the bottom of the cavity. The helical plates of the wheels are in line contact so that the piston crown 1 moves relative to the piston skirt 10 .

[0050] refer to Figure 14 , Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com