Radiant tube garbage incinerator

A technology of waste incinerator and radiant tube, which is applied in incinerator, combustion method, combustion type and other directions, can solve the problem of not being able to meet the needs of classified combustion and high-temperature detoxification, etc., and achieves the effect of reasonable internal structure, heat saving and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention is further described:

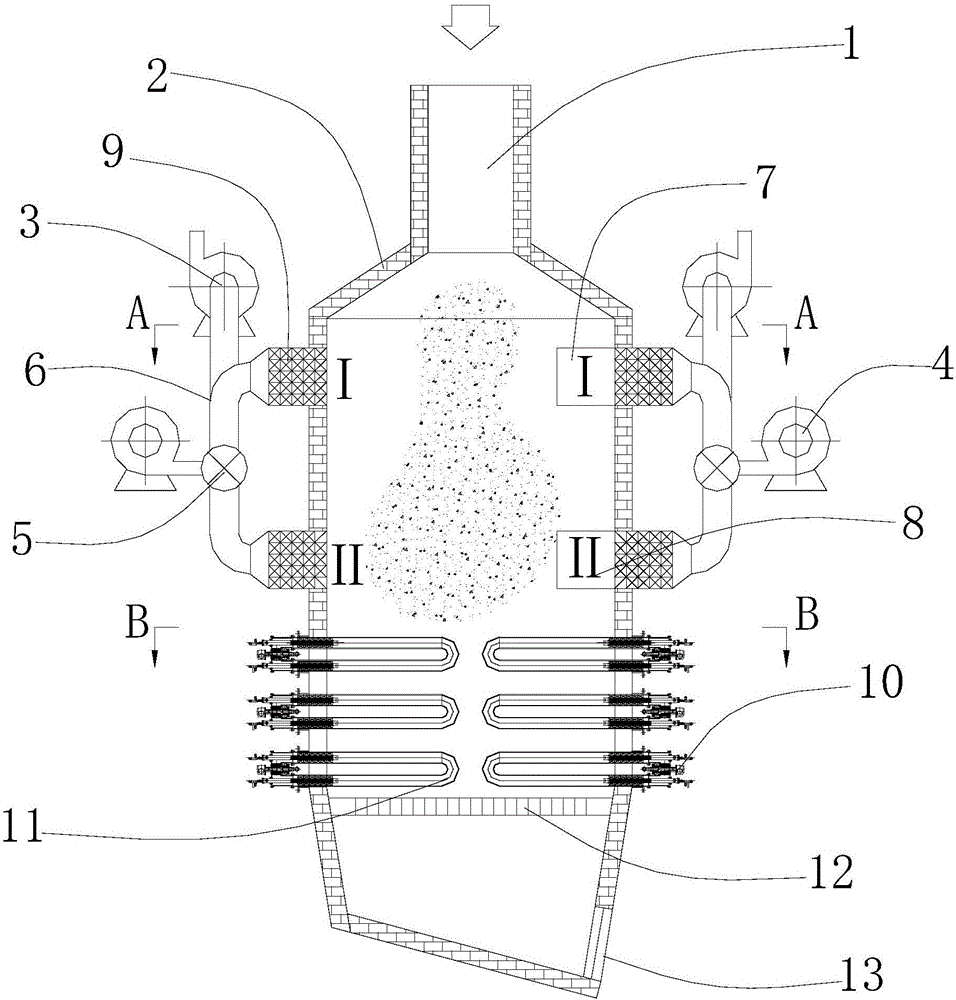

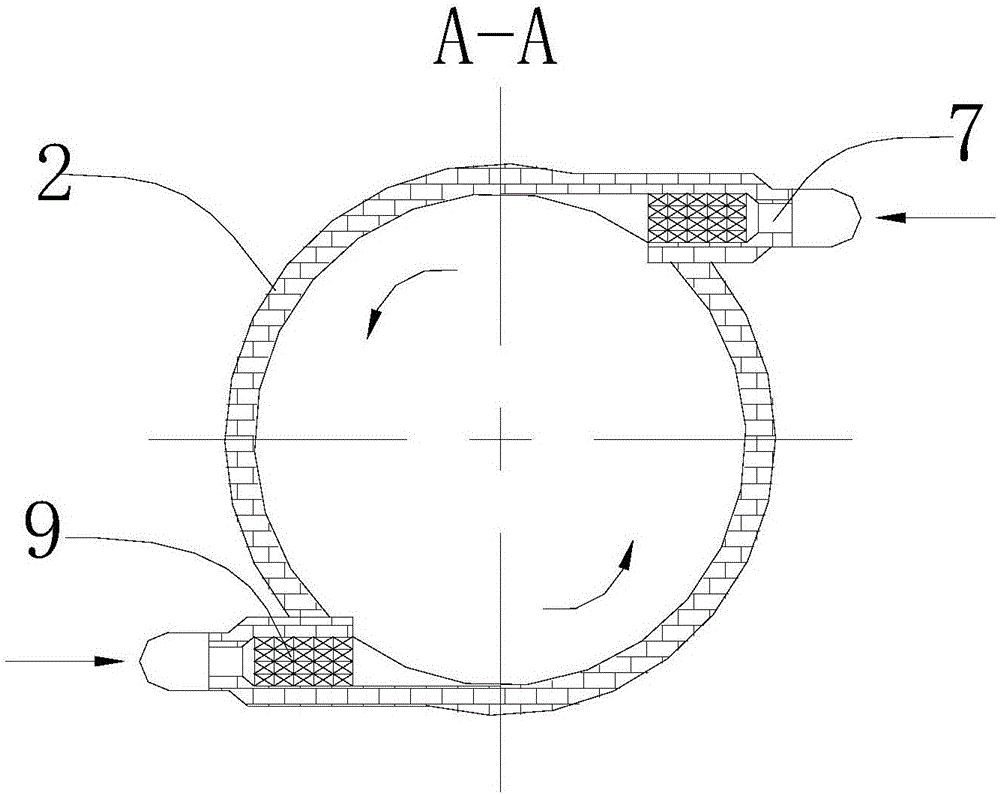

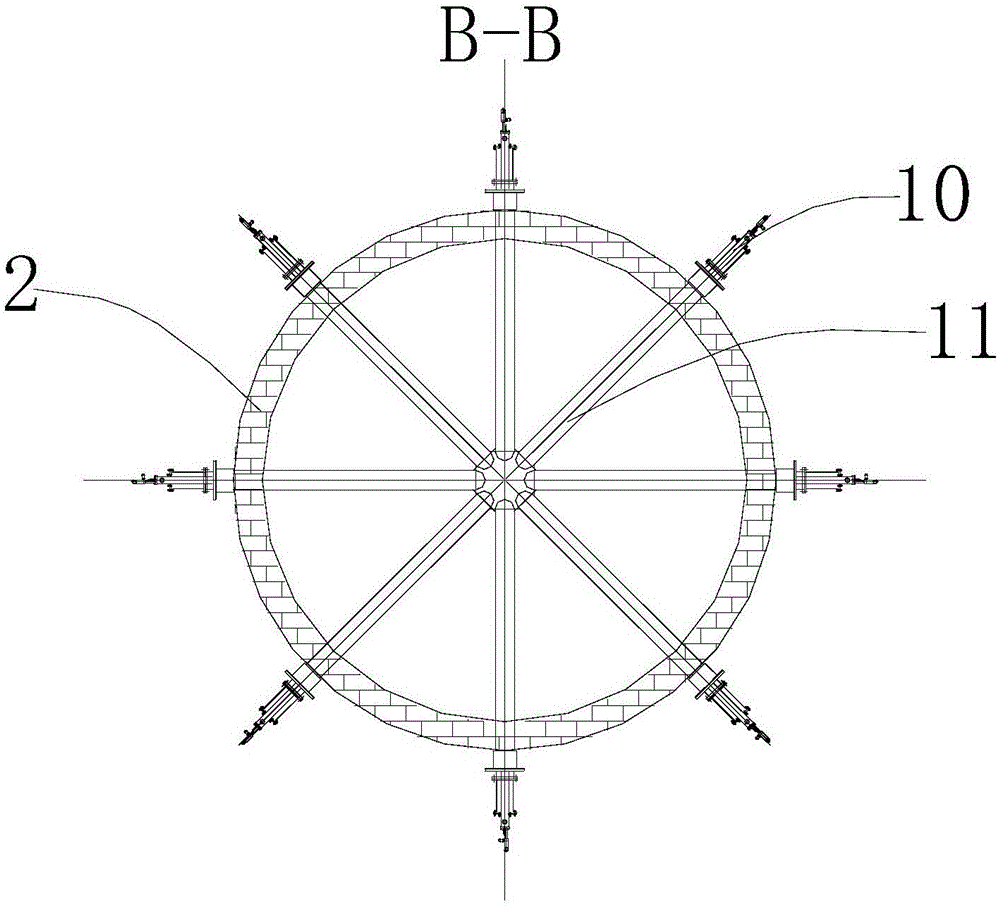

[0025] Such as figure 1 with figure 2 As shown, a radiant tube garbage incinerator includes a vertically arranged furnace body 2, the upper part of the furnace body 2 is provided with a garbage feeding port 1 for putting in garbage, and the upper part of the furnace body 2 is installed along the furnace body 2. A regenerative air supply device for generating swirling flow in the furnace. A multi-layer radiant tube burner 10 is installed at the bottom of the furnace body 2. The radiant tube 11 of the radiant tube burner 10 extends to the inside of the furnace body. The furnace body 2 A fire grate 12 is arranged below the inner radiant tube 11 , and a waste slag discharge port 13 is arranged at the bottom of the furnace body 2 .

[0026] The regenerative air supply device includes No. I tuyere 7 and No. II tuyere 8 arranged on the furnace body. No. I tuyere 1 and No. II tuyere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com