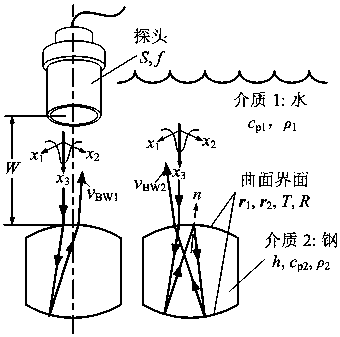

A method for evaluating the ultrasonic attenuation of metal grain size without the effect of surface diffusion

A technology of grain size and diffusion attenuation, which is applied in the direction of analyzing solids by using sound wave/ultrasonic wave/infrasonic wave, so as to improve practicability and reliability, and reduce systematic error and random error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

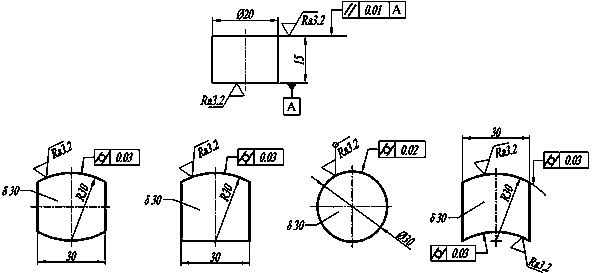

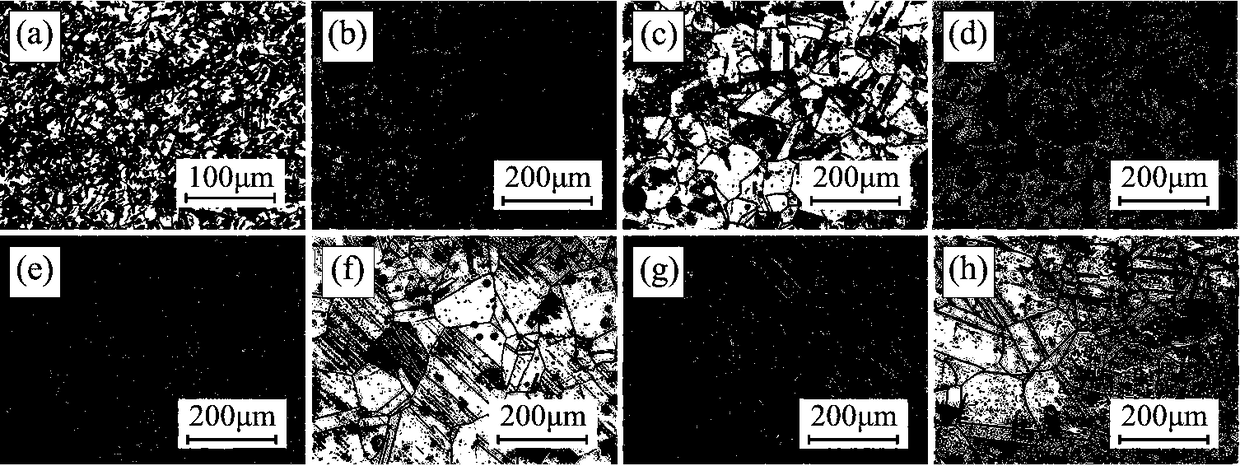

[0046] The specific implementation method is to select 304 stainless steel with the brand name of 06Cr19Ni10 to prepare the test block. In order to establish a grain size multi-frequency ultrasonic attenuation evaluation model that eliminates the influence of diffusion, it is necessary to use the test block with known grain size as a reference. Use the ultrasonic pulse signal generator / receiver to connect with the focusing probe to send and receive the pulse signal; use the motion control card and the motion platform to adjust the control probe to move up and down perpendicular to the surface to be tested, and use the high-speed data acquisition card on the computer to acquire and store the ultrasonic instrume...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com