Compound processing method of hemarthria sibirica

A bullwhip and microwave drying technology, which is applied to medical preparations containing active ingredients, drug combinations, and pharmaceutical formulas, etc., can solve problems such as difficult combination of nutritional raw materials, uneven heating of materials, and restrictions on application and development, and shorten the drying process. Improvement of time and production efficiency and shortening of drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

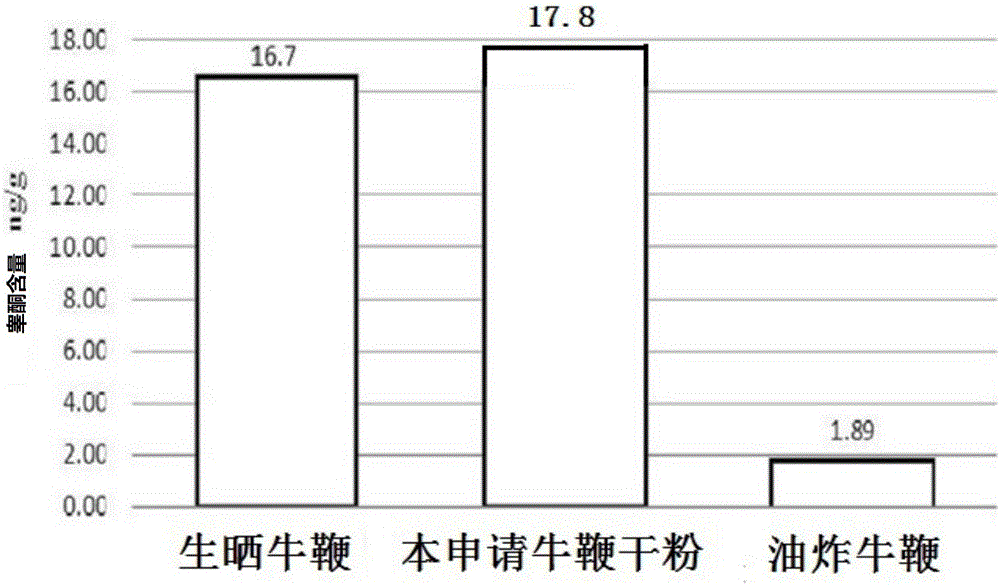

Image

Examples

Embodiment 1

[0058] A compound processing method of bullwhip, said method comprising the steps of:

[0059] Step 1, raw material pretreatment;

[0060] Step two, ultrasonic vacuum impregnation;

[0061] Step three, freezing;

[0062] Step 4, low temperature vacuum microwave drying;

[0063] Step five, crushing;

[0064] Step 6, hot air-infrared-microwave drying;

[0065] Step seven, packing.

[0066] Wherein, said step one includes the following steps:

[0067] Step 1), cut open the bullwhip, remove the surrounding fascia and fat, remove sundries, and wash with water;

[0068] Step 2), put the bullwhip after cleaning in step 1) into a container, add citric acid 12ml / kg, white wine 17ml / kg and ice water 3kg / kg respectively, soak for 4 hours, wash and drain for later use;

[0069] Step 3), put the bullwhip obtained in step 2) into another container, then add 4g / kg of baking soda, 3g / kg of salt and 3kg / kg of purified water, and soak for 4 hours at a water temperature of 26°C. Wash and...

Embodiment 2

[0090] A compound processing method of bullwhip, said method comprising the steps of:

[0091] Step 1, raw material pretreatment;

[0092] Step two, ultrasonic vacuum impregnation;

[0093] Step three, freezing;

[0094] Step 4, low temperature vacuum microwave drying;

[0095] Step five, crushing;

[0096] Step 6, hot air-infrared-microwave drying;

[0097] Step seven, packing.

[0098] Wherein, said step one includes the following steps:

[0099] Step 1), cut open the bullwhip, remove the surrounding fascia and fat, remove sundries, and wash with water;

[0100] Step 2), put the bullwhip after cleaning in step 1) into a container, add citric acid 15ml / kg, white wine 20ml / kg and ice water 3kg / kg respectively, soak for 5 hours, wash and drain for later use;

[0101] Step 3), put the bullwhip obtained in step 2) into another container, then add 5g / kg of baking soda, 5g / kg of salt and 5kg / kg of purified water, and soak for 4 hours at a water temperature of 27°C. Wash and...

Embodiment 3

[0122] A compound processing method of bullwhip, said method comprising the steps of:

[0123] Step 1, raw material pretreatment;

[0124] Step two, ultrasonic vacuum impregnation;

[0125] Step three, freezing;

[0126] Step 4, low temperature vacuum microwave drying;

[0127] Step five, crushing;

[0128] Step 6, hot air-infrared-microwave drying;

[0129] Step seven, packing.

[0130] Wherein, said step one includes the following steps:

[0131] Step 1), cut open the bullwhip, remove the surrounding fascia and fat, remove sundries, and wash with water;

[0132] Step 2), put the bullwhip after cleaning in step 1) into a container, add citric acid 10ml / kg, white wine 15ml / kg and ice water 2kg / kg respectively, soak for 4 hours, wash and drain for later use;

[0133] Step 3), put the bullwhip obtained in step 2) into another container, then add 1g / kg of baking soda, 1g / kg of salt and 2kg / kg of purified water, and soak for 3 hours at a water temperature of 25°C. Wash and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com