A rock wool cutting knife grinding device and grinding method thereof

A technology of cutting knives and rock wool, which is applied in the field of grinding processing, can solve problems such as low efficiency, achieve the effect of improving grinding efficiency, avoiding looseness and breakage, and facilitating installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

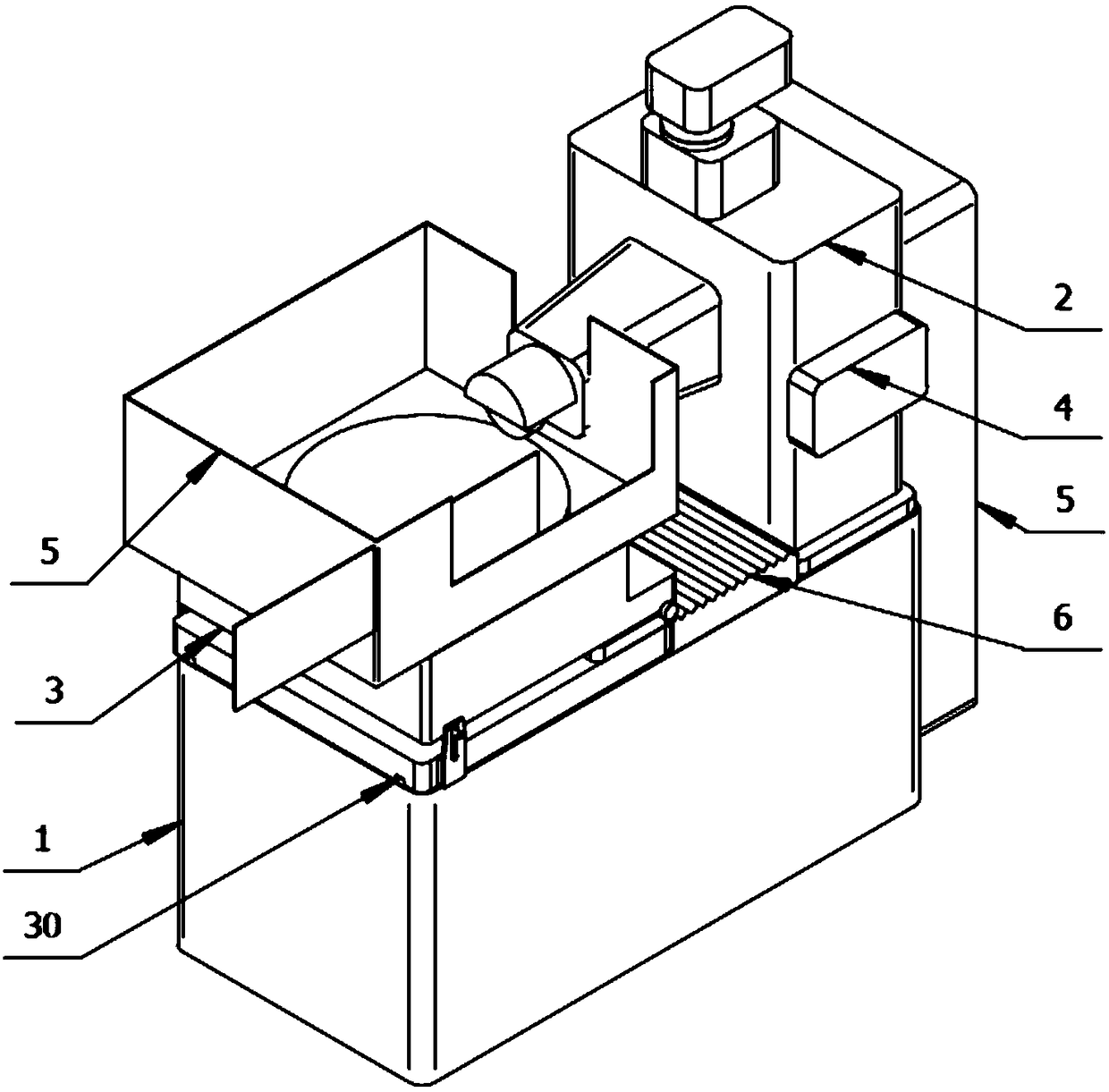

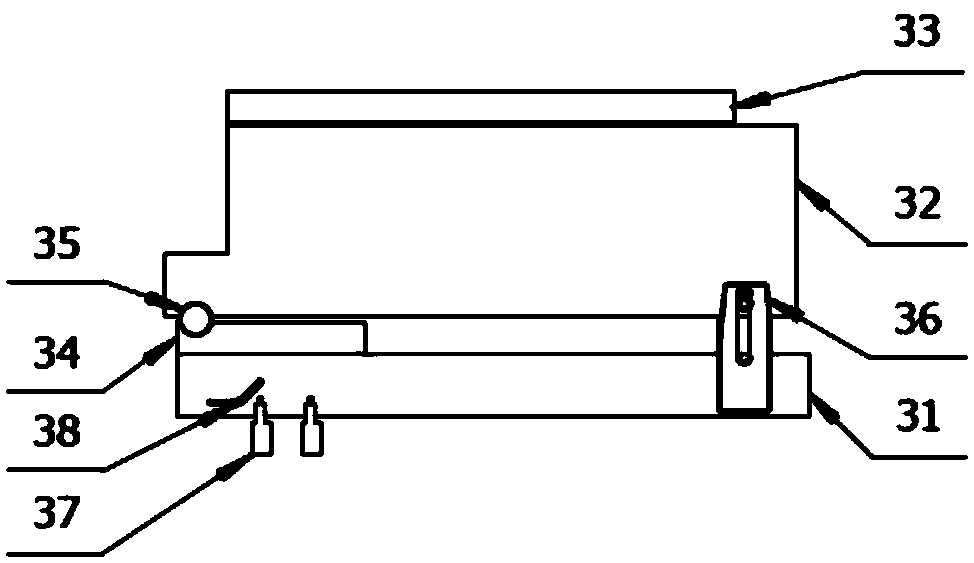

Embodiment 1

[0050] Such as Figure 1-4 As shown, a rock wool cutting knife grinding device includes a frame 1, a main shaft transmission unit 2 and a cutter head transmission unit 3, the main shaft transmission unit 2 is fixed on one end of the upper surface of the frame 1, and the frame 1 includes Guide rail 11, guide rail 11 is fixed on the other end of frame 1 upper surface, cutterhead transmission unit 3 is positioned on guide rail 11, cutterhead transmission unit 2 comprises mobile platform 31, cutterhead transmission case 32, cutterhead 33, rotating platform 34, Rotary shaft 35 and adjusting plate 36, mobile platform 31 bottoms are provided with guide groove 30, and mobile platform 31 is flexibly connected with guide rail 11 on the frame 1 by guide groove 30 at the bottom, and the bottom of rotating platform 34 is fixed on mobile platform 31 tops, rotates The shaft 35 is fixed on the top of the rotary platform 34, the bottom of the cutterhead transmission box 32 is flexibly connecte...

Embodiment 2

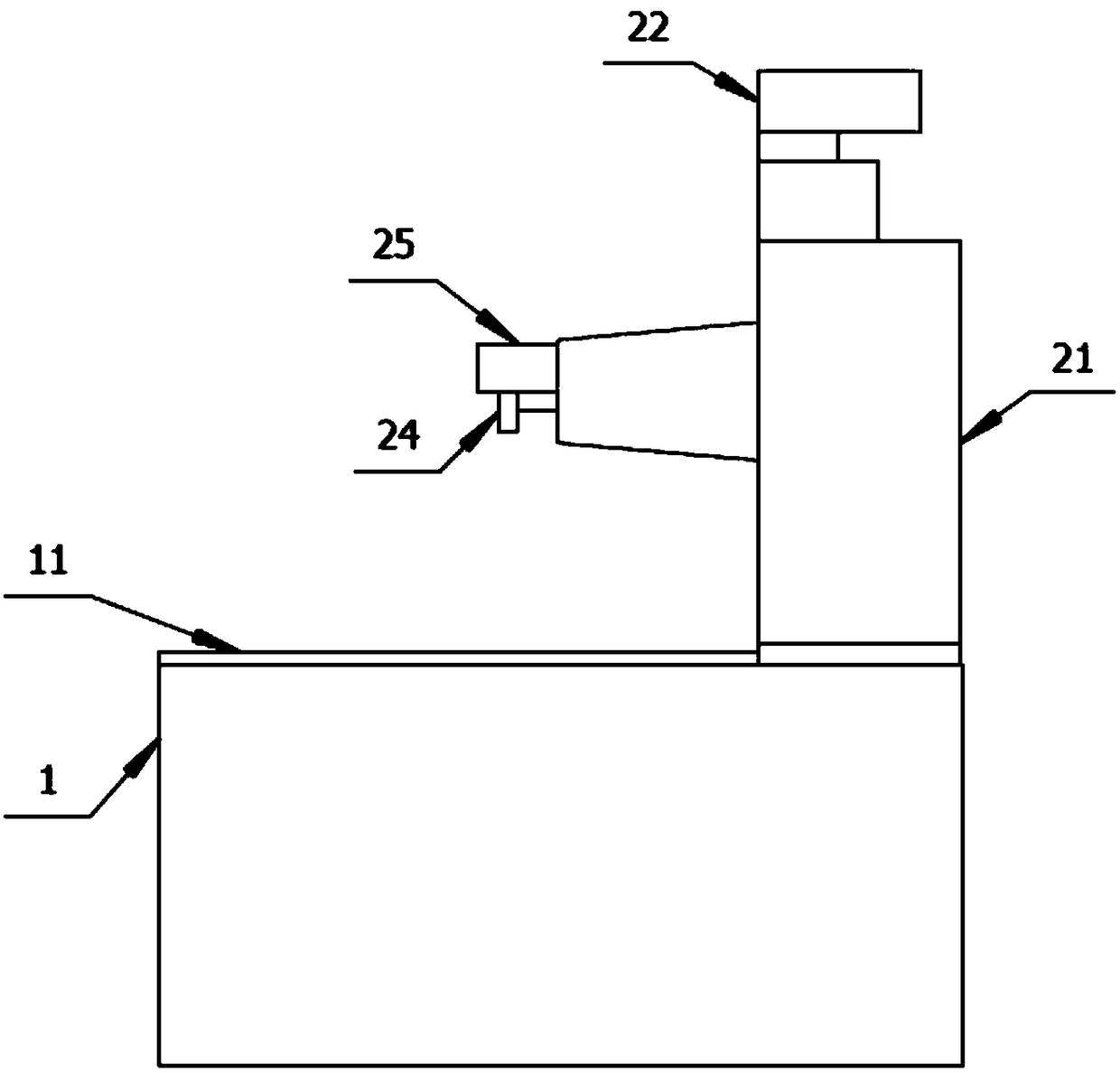

[0053] A rock wool cutting knife grinding device of this embodiment is similar to Embodiment 1, the difference is that the main shaft transmission unit 2 includes a main shaft transmission box 21, a motor 22, a grinding wheel 24 and a grinding wheel guard 25, the main shaft transmission Case 21 is fixed on the frame 1, and motor 22 links to each other with the input shaft of main shaft transmission case 21, and emery wheel 24 links to each other with the output shaft of main shaft transmission case 21, and emery wheel shield 25 is fixed on the input shaft end of main shaft transmission case 21.

[0054] In this embodiment, the main shaft transmission box 21 is provided with a gear transmission mechanism, which can transmit the torque output by the motor 22 to the grinding wheel 24 connected to the input shaft of the main shaft transmission box 21, by controlling the internal gear mechanism of the main shaft transmission box 21 and the motor The operation of 22 can reasonably co...

Embodiment 3

[0056] A kind of rock wool cutting knife grinding device of this embodiment is similar to Embodiment 2, the difference is that the cutter head transmission unit also includes a limit switch 37 and a limit plate 38, and the limit plate 38 is fixed on the moving On the platform 31, the limit switch 37 is fixed on the frame.

[0057] In this embodiment, when the cutterhead transmission unit 3 moves on the guide rail 11 of the frame 1, when the limit plate 38 fixed on the mobile platform 31 touches the limit switch 37 on the frame 1, the cutterhead transmission unit 3 will stop moving, avoiding the collision between the cutter head transmission unit 3 and the main shaft transmission unit 2.

[0058] Present embodiment also comprises electric box 7 and control unit 4, and electric box 7 is fixed on one end of fixed main shaft transmission unit 2 on the frame 1, and the motor 22 of drive motor of cutter head transmission box 32 and main shaft transmission box is all connected with c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com