Weather-resistant decorative film and preparation method thereof

A decorative film and weather-resistant technology, applied in the field of decoration, can solve the problems of high price, yellowing and graying of doors and windows, and achieve the effect of reducing production costs, improving weather resistance, and realistic patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In the first step, the constituent materials, ASA and PVC, are dried at 80-90°C for 3-5 hours for subsequent co-extrusion;

[0020] The second step is to mix the dried ASA and PVC in a certain proportion, lay a layer of PVC on the top of one layer of ASA, and then continue to spread another layer of ASA, and pass through two extruders under the environmental conditions of 185-230°C. co-extrusion;

[0021] In the third step, the co-extruded profiles are sequentially processed through calendering, casting, calendering, film blowing, etc., wherein the roller temperature is 100°C and the line speed is 20 m / min;

[0022] The fourth step is to trim the edge with a disc knife;

[0023] The fifth step, winding: 500-1000 m / roll.

Embodiment 2

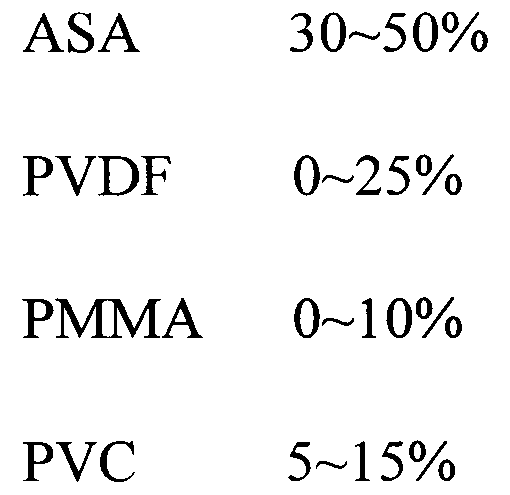

[0025] The first step is to dry the constituent materials such as ASA, PVDF, PMMA and PVC at 80-90°C for 3-5 hours;

[0026] In the second step, the dried ASA, PVDF, PMMA and PVC are mixed according to a certain ratio, specifically 3 layers of ASA, 1 layer of PVC, 1 layer of PMMA and 1 layer of PVDF, respectively, under the environmental conditions of 185-230 ℃, Co-extruded by two or three extruders;

[0027] In the third step, the co-extruded profiles are sequentially processed through calendering, casting, calendering, film blowing, etc., wherein the temperature of the roller is 110°C, and the line speed is 15 m / min;

[0028] The fourth step is to trim the edge with a disc knife;

[0029] The fifth step, winding: 500-1000 m / roll.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com