Spunlace hydroentanglement into cloth system

A spunlace and hydraulic technology, applied in needle punching machines, non-woven fabrics, textiles and papermaking, etc., can solve problems such as the influence of fiber web quality, the larger gap between trawl curtains, and the impact on the tensile strength of woven fabrics. Adaptability, the effect of preventing safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

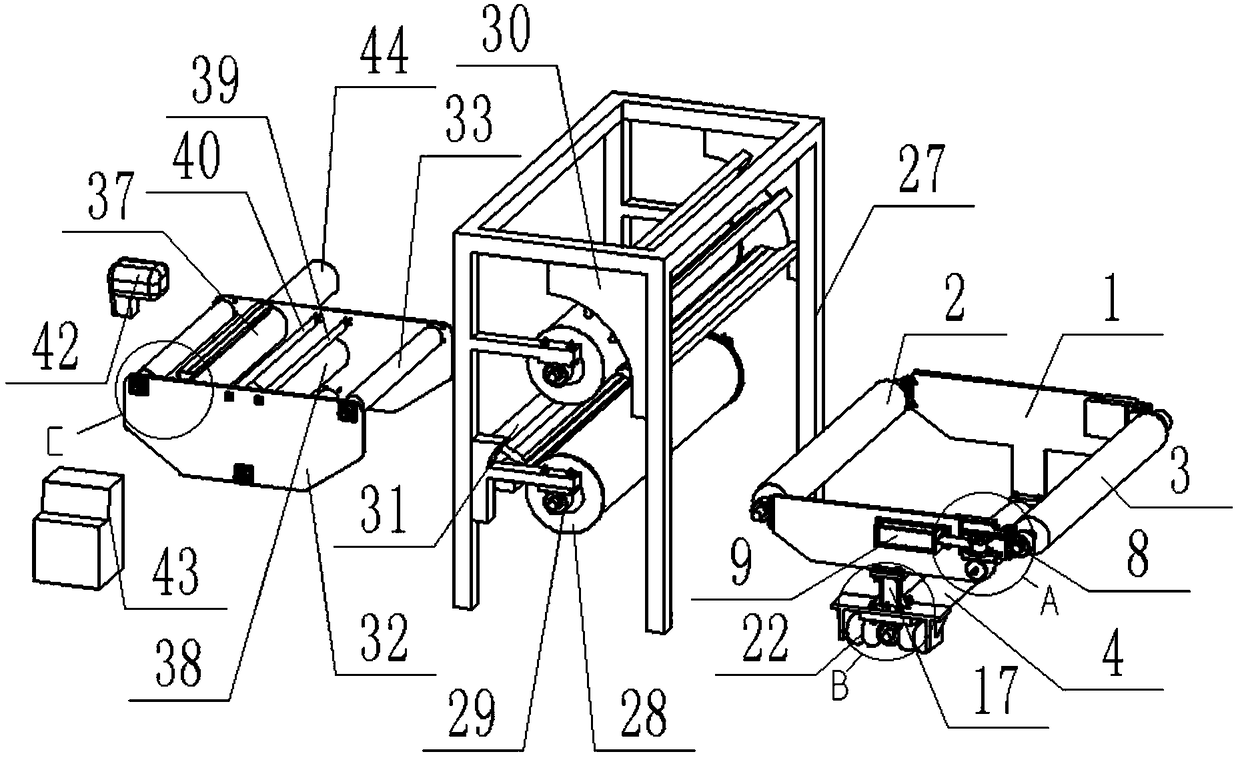

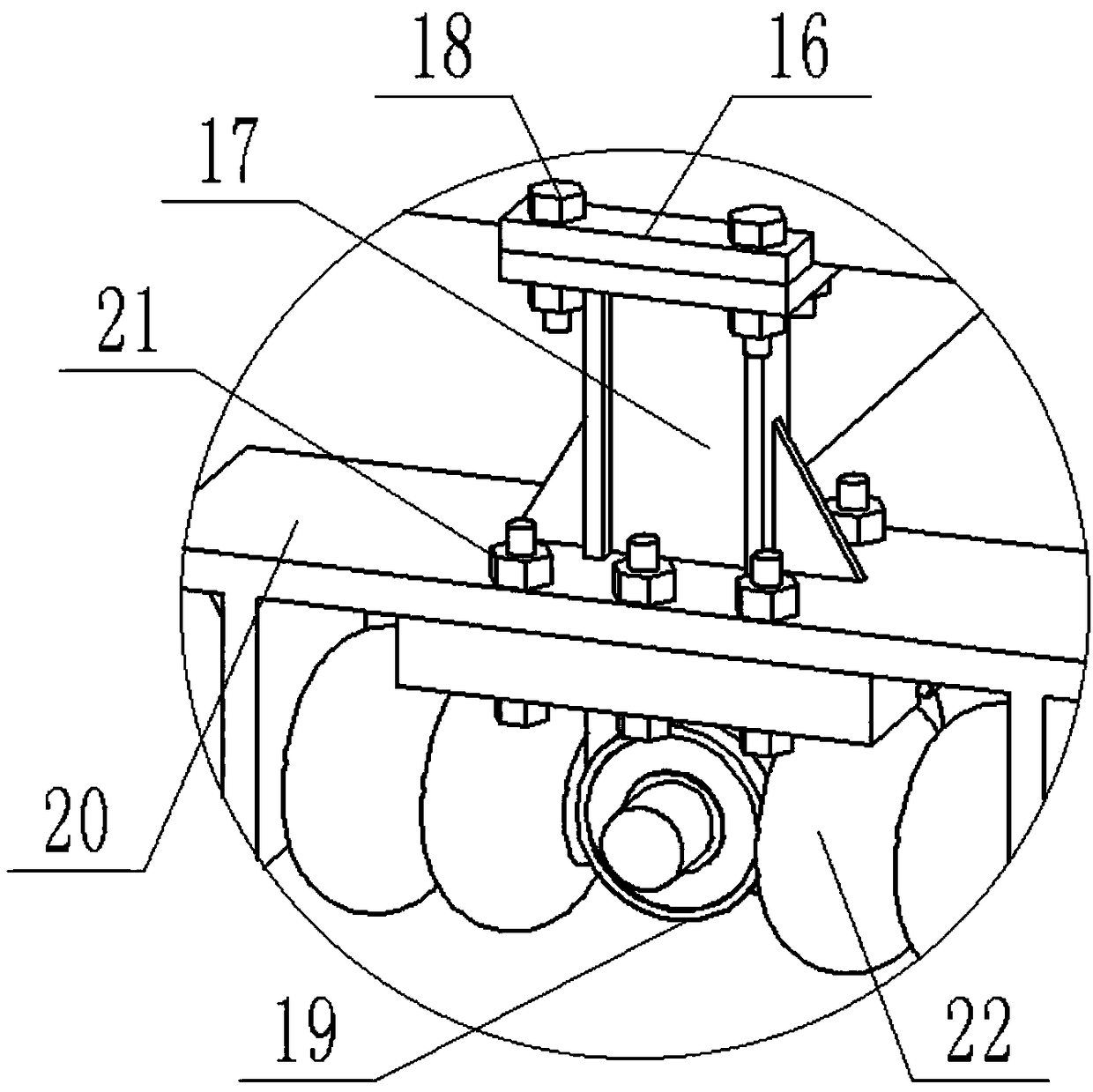

[0029] according to Figure 1 to Figure 7 As shown, a hydroentangling cloth system of a spunlace machine includes a tensioning and deviation correction device for a spunlace machine, a entanglement cloth device for a spunlace machine and a dehydration platform for a spunlace machine, and the tensioning and deviation correction devices for a spunlace machine are used for the spunlace machine. The deviation correction device is located on the right side of the entanglement device of the spunlace machine, the dehydration platform of the spunlace machine is located on the left side of the entanglement device of the spunlace machine, and an infrared moisture measuring instrument is installed on the left side of the dehydration platform of the spunlace machine.

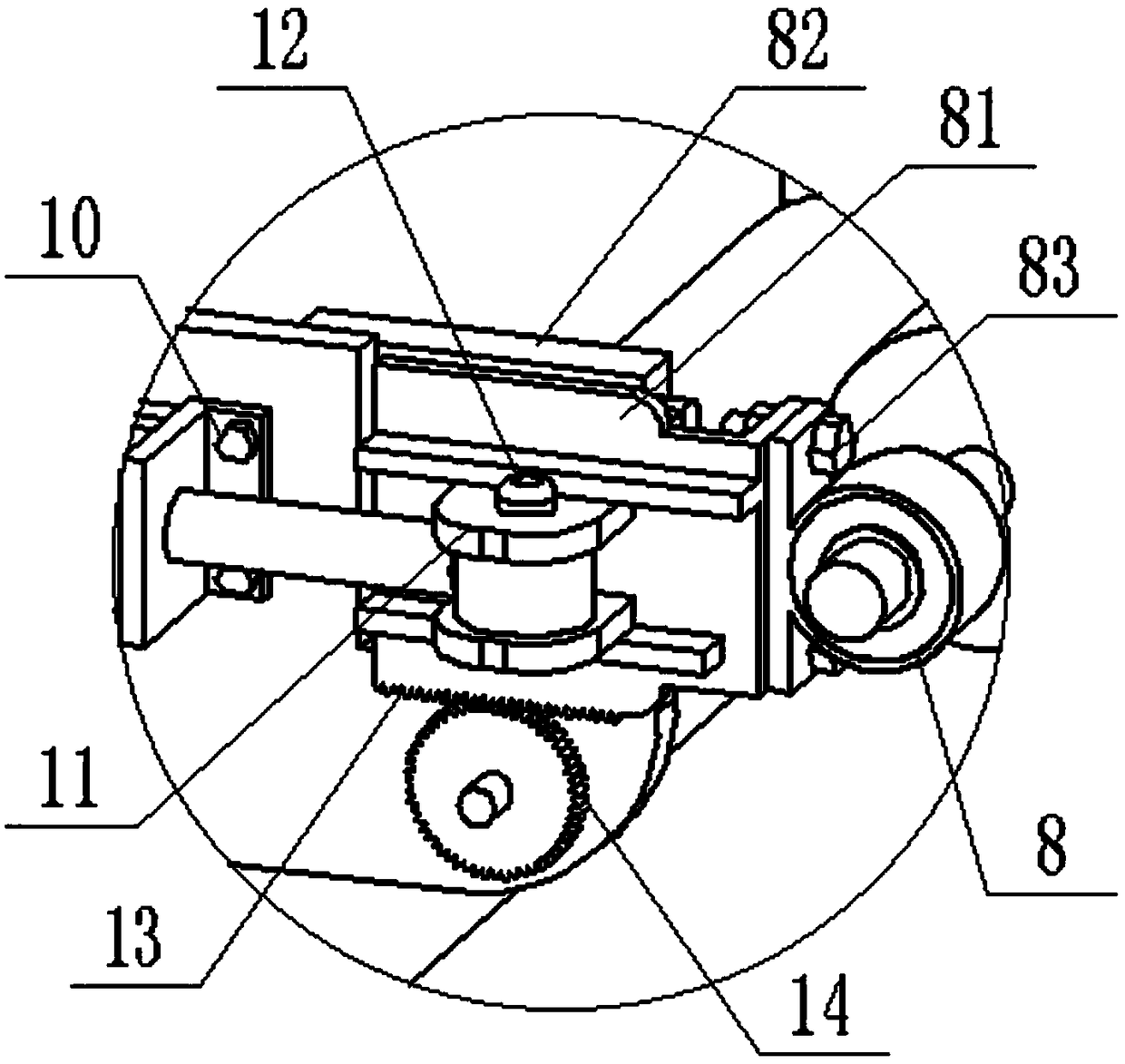

[0030] Further, the tensioning and deviation correction device for the spunlace machine includes a housing I1, a transmission roller I2, a tension roller 3 and a deviation correction roller 4, and the transmission roller I2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com