Composite concrete prefabricated beam

A prefabricated assembly and concrete technology, which is applied in the direction of structural elements, building components, and long-strip structural components for load-bearing, to achieve the effects of reducing beam cross-section, good synergistic workability, and reducing beam self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

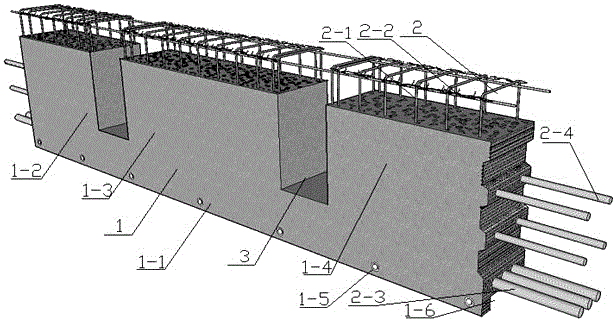

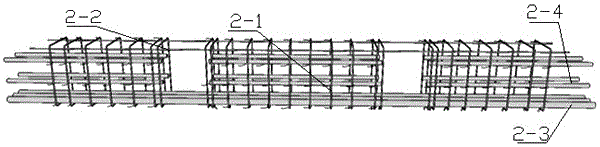

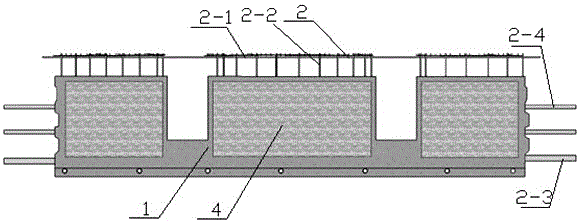

[0020] Such as figure 1 , 2 , shown in 3, the present invention comprises the beam housing 1 that is cuboid, and beam housing 1 adopts active powder concrete casting molding, and active powder concrete is made of Portland cement, silica fume, admixture, fine aggregate, high-efficiency water-reducing Among them, Portland cement has a strength grade of 42.5 and above, the SiO2 content in silica fume is more than 90%, the admixture is ultra-fine slag powder or finely ground Class I fly ash, and the fine aggregate is the largest particle size Quartz sand or washed river sand not larger than 2.5mm, high-efficiency water reducer is polycarboxylate water reducer, water reducing rate is more than 30%, compressive strength of active powder concrete is 130MPa ~ 150MPa, flexural strength is 20MPa ~ 30MPa, active powder Concrete is self-compacting and poured without vibration.

[0021] The beam shell 1 is provided with a reinforcement cage 2, and the reinforcement cage 2 protrudes upwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com