Hot-rolled double-layer bimetallic composite coil/plate decoiling, centering, pinching and trimming unit

A technology of bimetallic and composite rolls, which is applied in the direction of metal processing equipment, shearing devices, and attachments of shearing machines, etc., can solve problems such as difficulty in recycling and distortion of side materials, and achieve the goal of reducing space occupation and cost input effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The specific structure, working principle and technical effect of each component of the unwinding, centering, pinching and trimming unit of the present invention will be described in detail below in conjunction with the accompanying drawings. Except for the components mentioned below, the other components involved in the unit all adopt known technologies, and will not be repeated here.

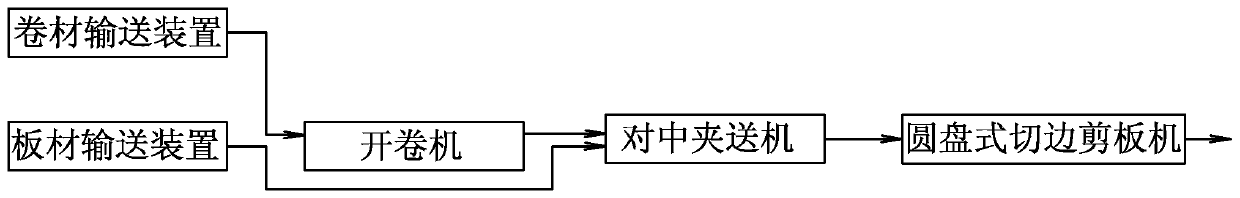

[0083] figure 1 It shows the process flow of the uncoiling, centering, pinching and trimming unit of the present invention.

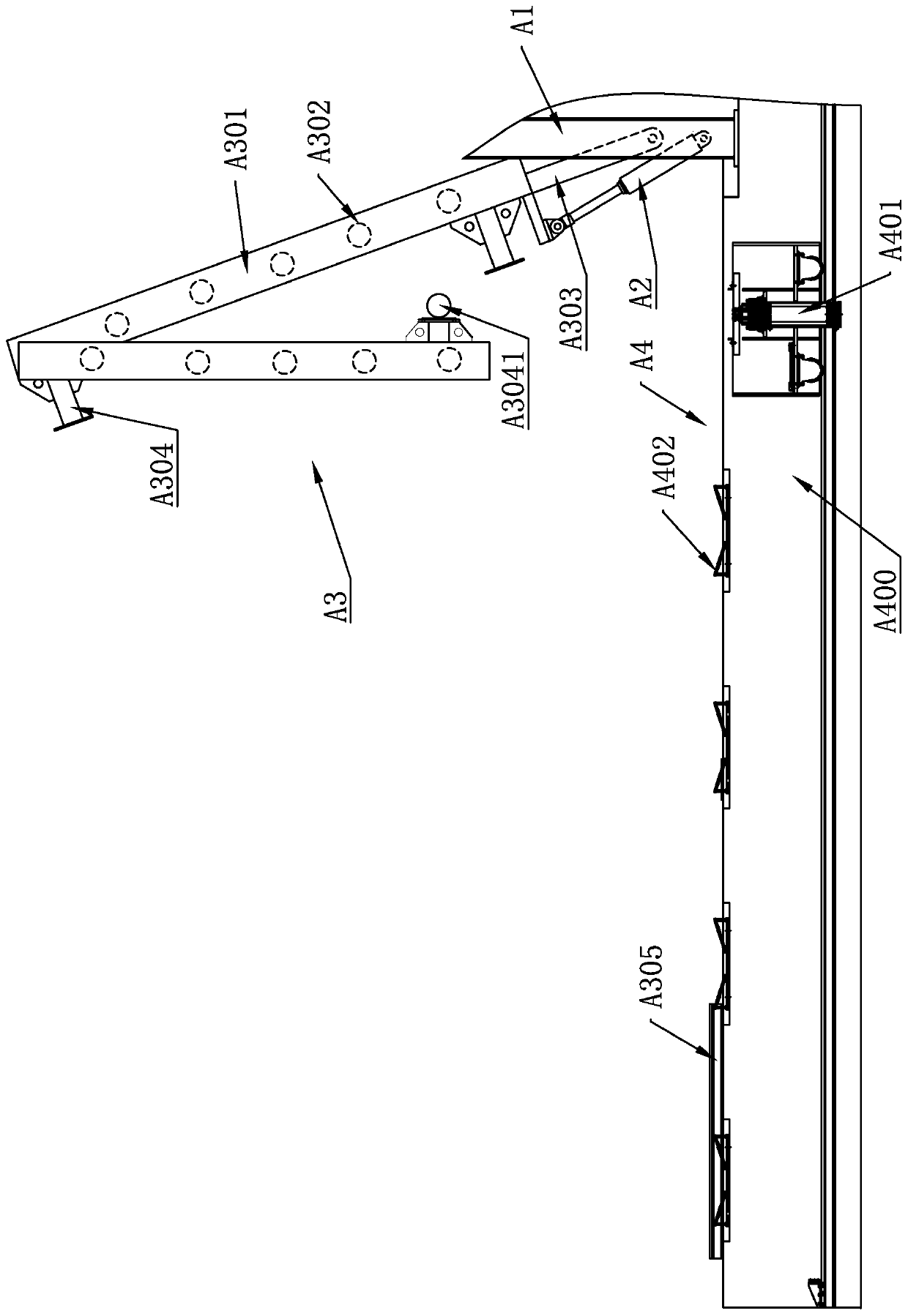

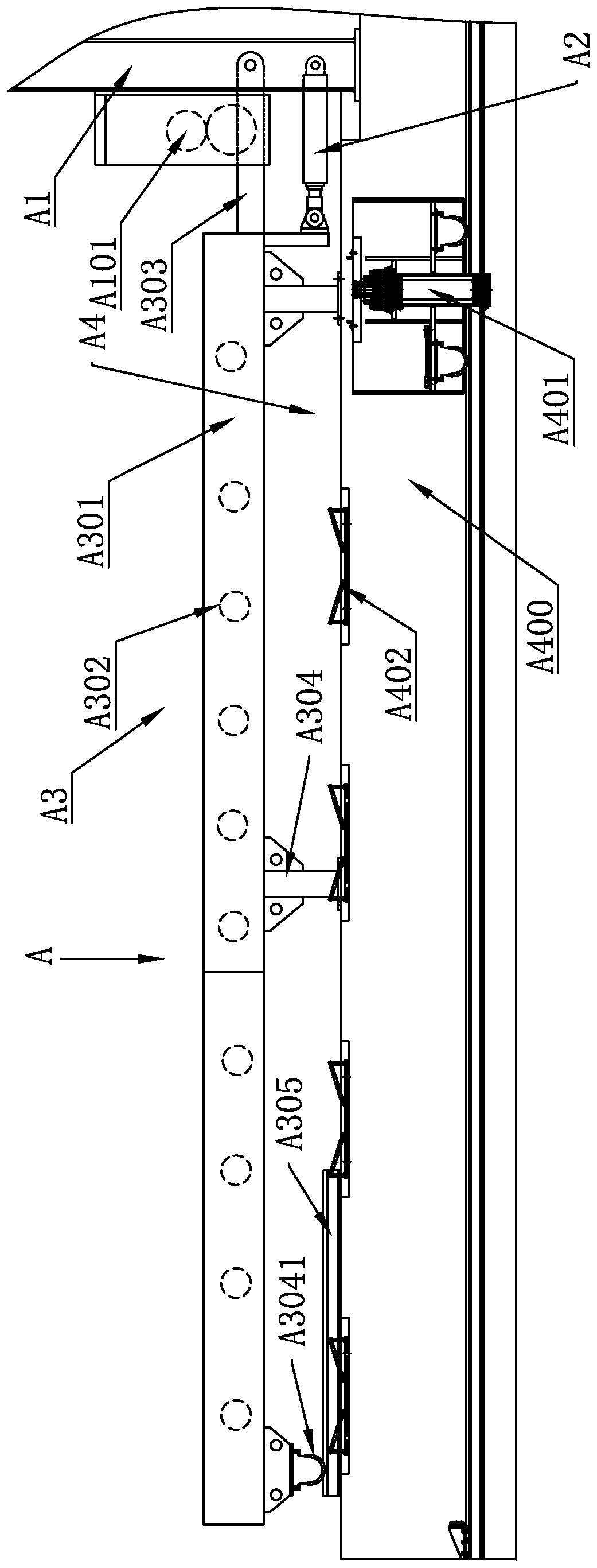

[0084] Figure 2 to Figure 5 Shown is the feeding device of the present invention.

[0085] Such as Figure 2 to Figure 5Commonly shown, the plate conveying device A3 driven by the first power device A2 is hinged on the first frame A1, and the coil conveying device A4 is also arranged upstream of the first frame A1; the plate conveying device A3 is in working condition , the plate conveying device A3 and the coil conveying device A4 are arranged correspondin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com