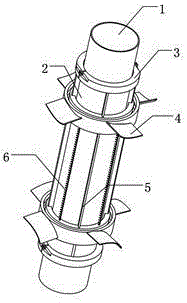

Vortex induced vibration suppression device with axial direction slip rotary impeller pair and method

A technology of vortex-induced vibration and rotating impeller, which is applied in the direction of drilling equipment, earthwork drilling, drill pipe, etc., which can solve the problems of inability to adjust independently, consumption, difficulties, etc., and achieve the best vortex-induced vibration suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

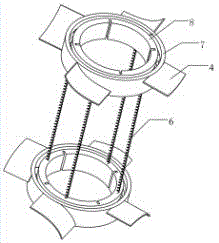

[0032] The device of the present invention can be used as a basic unit, arranged in series on the standpipe 1 according to a certain distance, so as to realize the suppression of vortex-induced vibration in different parts.

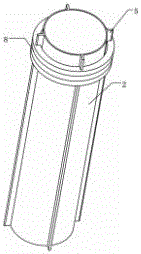

[0033]When installing on site, first install the sleeve 2, put the sleeve 2 on the outer wall of the riser 1, and then put the inner ring 8 of the upper and lower rotating parts on the sleeve 2, so that the inner wall surface of the inner ring 8 of the rotating part slides The groove matches the slide rail 5 on the outer wall of the sleeve 2, and the opening of the threaded hole 11 of the inner ring 8 of the upper rotating part faces downward, the opening of the threaded hole 11 of the inner ring 8 of the lower rotating part faces upward, and the upper and lower rotating parts The threaded holes 11 of the inner ring 8 are aligned in pairs. Next, insert the fixing hooks 10 into the four threaded holes 11 of the inner rings 8 of the upper and lower rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com