Coal bed gas directional well injection/fall-off well testing device and method thereof

A testing device and directional well technology, which is applied in the direction of wellbore/well valve device, wellbore/well components, measurement, etc., to achieve the effect of convenient operation, wide application and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

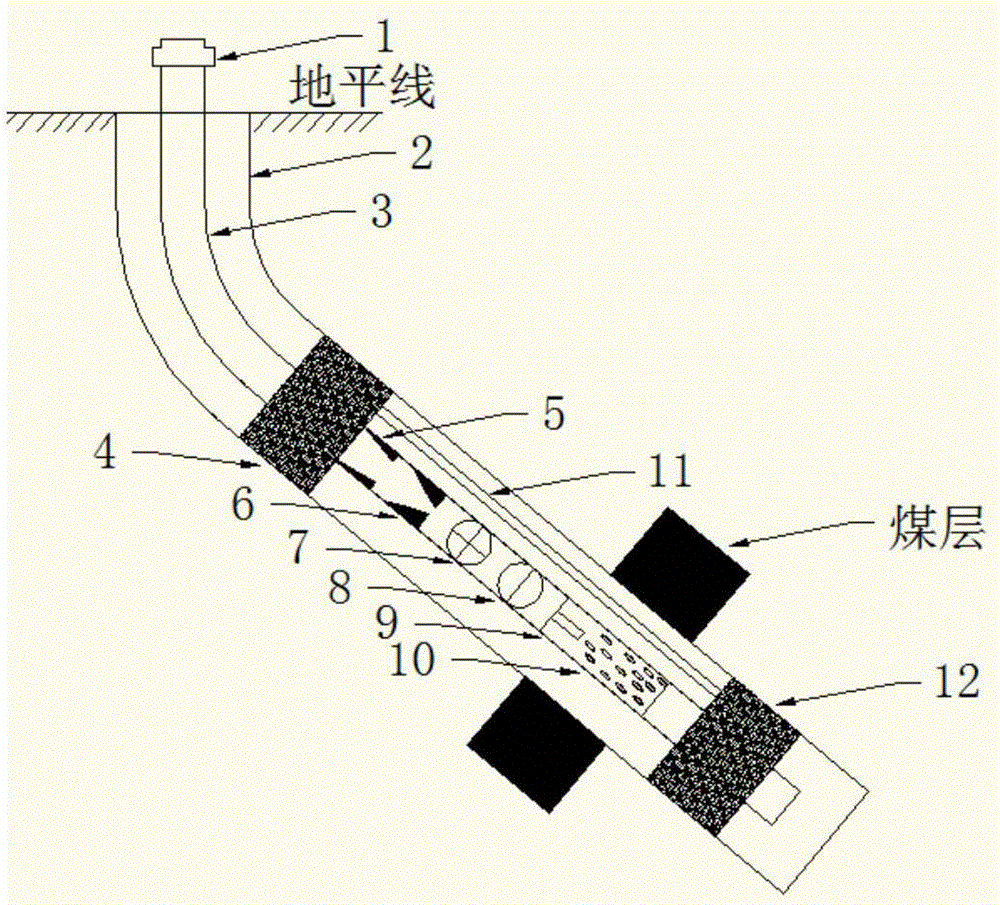

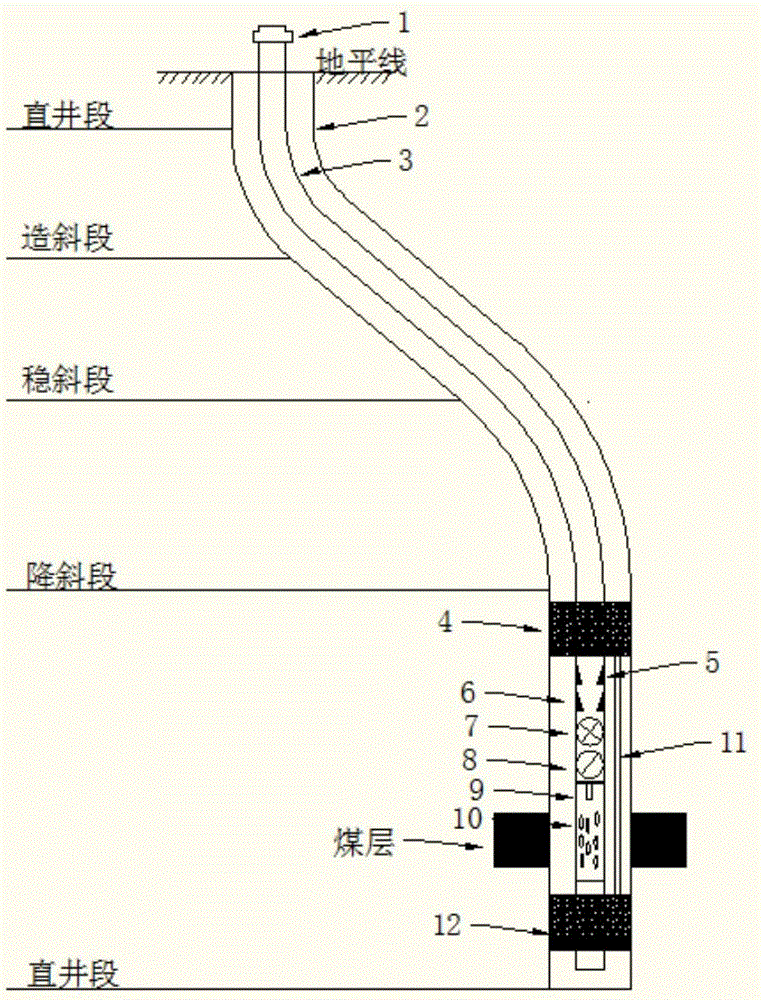

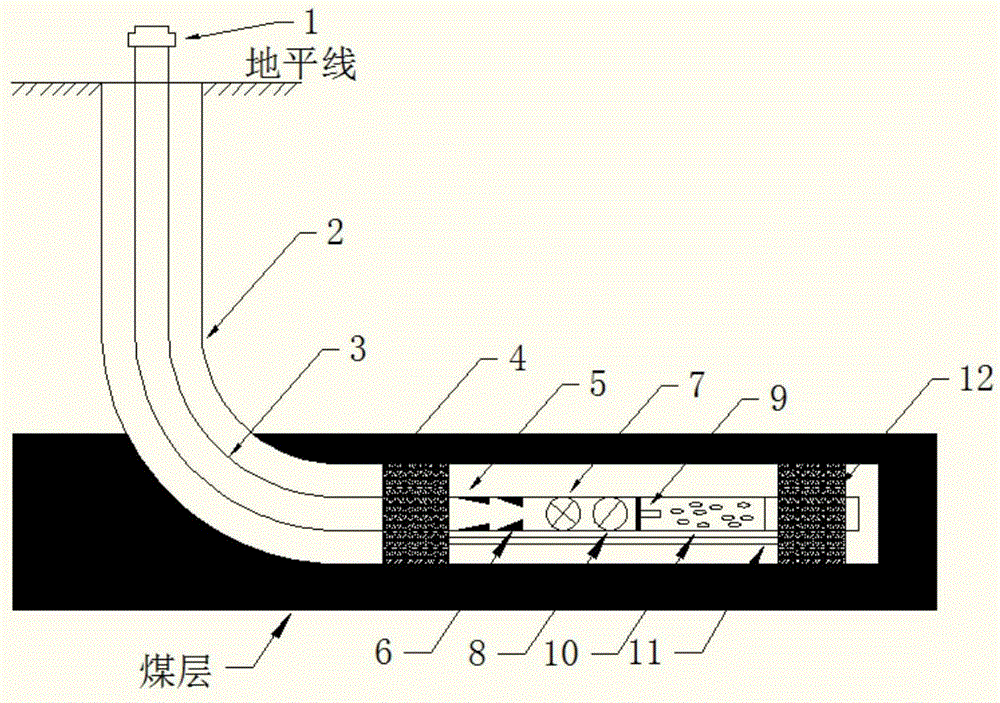

[0083] Well SL01 is located in a certain place. It is a coalbed methane directional well. The wellbore is perpendicular to the coal seam. The full angle change rate of 3 consecutive points in the inclined section is ≤3° / 30m. The secondary wellbore structure is adopted. The production casing is φ139.7mm. The perforation position of No. 41 coal seam is 668.20-675.30m, and the thickness of the coal seam is 7.10m.

[0084] Injection / pressure drop test adopts φ105mm lower packer, φ73.0mm screen pipe, φ6.35mm expansion pipeline, φ60.3mm electronic pressure gauge holder, φ82mm downhole switch valve, φ73.0mm ball seat tray, φ60.3mm small Ball seat, φ73.0mm large ball seat, φ105mm upper packer, φ73.0mm tubing, φ73.0mm wellhead device, φ1 / 2in, P=35MPa wellhead high pressure valve, φ19.00mm, P=35MPa high pressure manifold, Q =123L / min, P=25MPa high pressure pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com