A variable compression ratio rotary engine with reciprocating arc motion

A rotary engine, circular motion technology, applied in combustion engine, engine control, machine/engine, etc., can solve the problems of serious pollution, low thermal efficiency, hindering the promotion of triangular rotary engine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

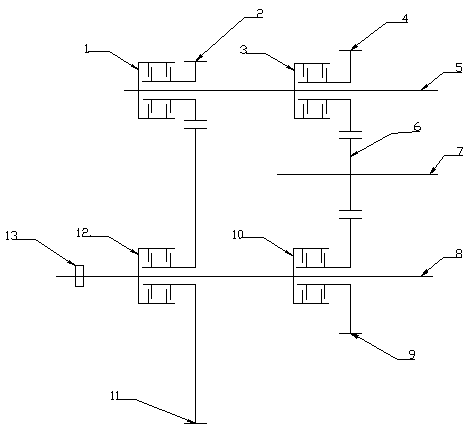

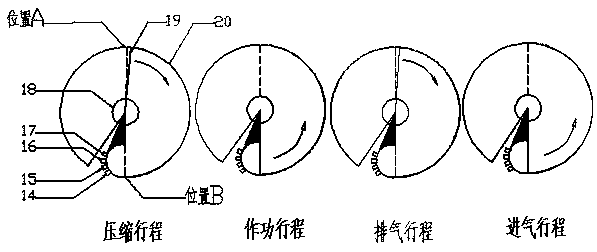

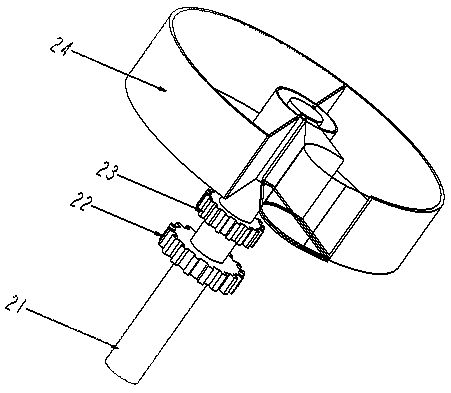

[0031] Such as figure 1 , 2 , 3, a kind of reciprocating arc motion variable compression ratio rotary engine of the present invention comprises: vehicle-mounted ECU, cylinder block 20, rotor 19, arc-shaped plate 18 rigidly connected with rotor 19, fuel injection device 17 , ignition device 16, intake valve 15, exhaust valve 14, angular displacement sensor 13, fourth clutch 12, fifth gear 11, third clutch 10, fourth gear 9, engine shaft 8, reversing shaft 7, the first Three gears 6, output shaft 5, second gear 4, second clutch 3, first gear 2, first clutch 1. Wherein the rotor 19 is rigidly connected with the engine shaft 8, the arc plate 18 can rotate together with the rotor 19, and the angular displacement sensor 13 is installed on the engine shaft 8, and the arc plate 18 has three mutual contact positions with the cylinder block 20 when rotating, each There is a sealing strip at the first position, the fifth gear 11 and the fourth gear 9 are sleeved on the engine shaft 8 w...

no. 2 example

[0038] In order to speed up the separation and coupling speed of each clutch, the first clutch 1, the second clutch 3, the third clutch 10, and the fourth clutch 12 all adopt electromagnetic rheological devices. By giving the first clutch 1, the second clutch 3, and the third Different control voltages of the clutch 10 and the fourth clutch 12 control the disengagement or engagement of the first clutch 1 , the second clutch 3 , the third clutch 10 and the fourth clutch 12 .

[0039] Finally, the method for realizing the variable compression ratio of the engine is explained:

[0040] The angular displacement sensor can continuously detect the rotation angle of the rotor relative to the position B. The vehicle-mounted ECU detects the rotation angle of the rotor 19 relative to the position B in real time through the angular displacement sensor 13. When the angle reaches the angle value set by the system, the vehicle-mounted ECU controls the hydraulic pressure. The system leads to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com