Impeller optimization design method for preventing targeted energy transfer phenomenon during vibration of impeller

A technology of energy transmission and impeller vibration, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems affecting the safe and reliable operation of fans, aggravate impeller vibration, and weaken the rigidity of impeller structure, so as to achieve safe and reliable long-term operation, The effect of reducing the failure rate and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Frequency pass band and forbidden band of embodiment 1 ideal impeller

[0089] A centrifugal impeller

[0090] Fault phenomenon: Cracks appear at the inlet ring of the impeller cover

[0091] Elimination method: adjust the number of blades of the inlet reflux to Z=14

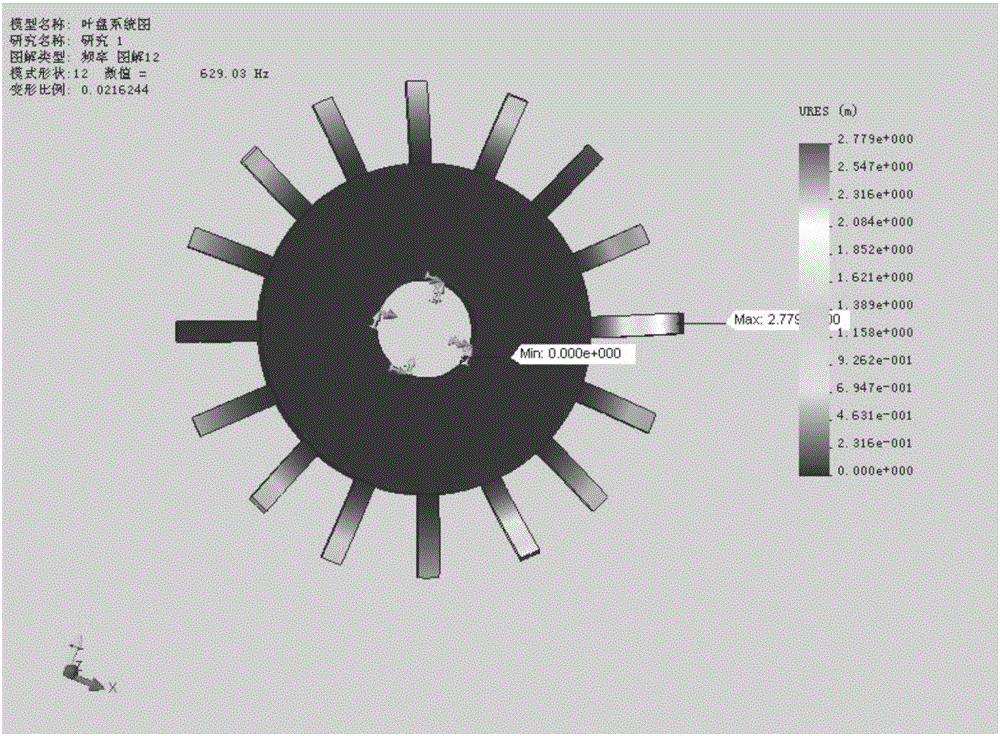

[0092] The main dimensions and technical parameters of the impeller: diameter D = Φ1020mm, blade number Z = 19, blade thickness δ = 8mm, working speed n = 5545r / min, material: alloy steel.

[0093] Relevant parameters of the compressor unit: the total number of stages: 3 stages, the stage number of the impeller: the third stage, the number of blades of the inlet blade reflux device Z 1 =18.

[0094] Excitation source: the frequency of the excitation force caused by the imported reflux The frequency of the exciting force caused by the blades at the exit of the impeller

[0095] Finite element model of the impeller: 10-node tetrahedral solid elements are used to discretize the entire impeller, with ...

Embodiment 2

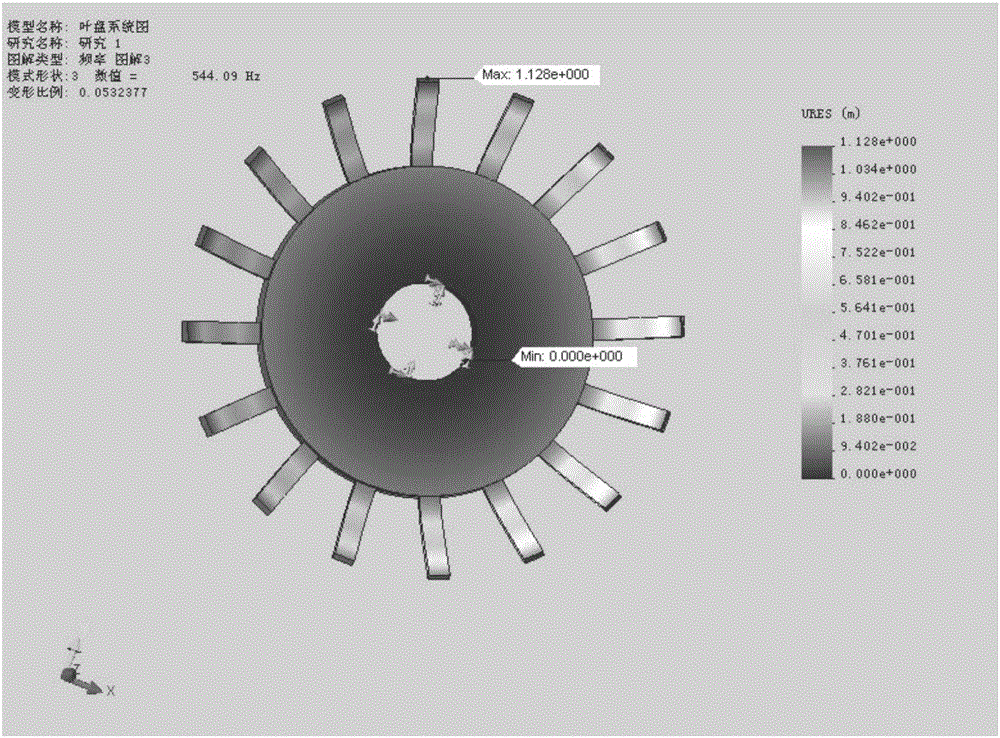

[0098] Example 2 The effect of detuning on targeted energy transfer

[0099] The influence of different detuning forms and different detuning amounts of the impeller on the impeller mode localization that occurs during the targeted energy transfer process is analyzed.

[0100] The impeller modes are very sensitive to some detuning, and while the modal frequency values do not change much, the mode shapes change considerably. In the case of causing detuning, the frequency band gap value is very close to the excitation force frequency value 1663.5Hz caused by the reflux prerotator blade. The small change in the impeller structure caused by detuning results in a large difference from the ideal impeller frequency band gap, which is manifested by the fact that some frequencies that would ideally fall in the frequency pass band become frequency band gaps in the case of detuning. From the point of view of the mode shape, the parts where the mode localization of the mode shape of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com