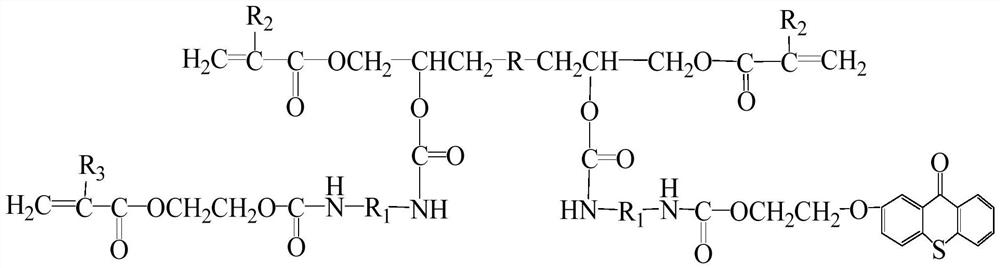

Thioxanthone polyurethane modified epoxy acrylate LED light-cured resin

A technology of thioxanthone polyurethane and epoxy acrylate, applied in polyurea/polyurethane coatings, applications, coatings, etc., can solve problems such as poor solubility, and achieve easy reaction, excellent adhesion, and excellent system compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

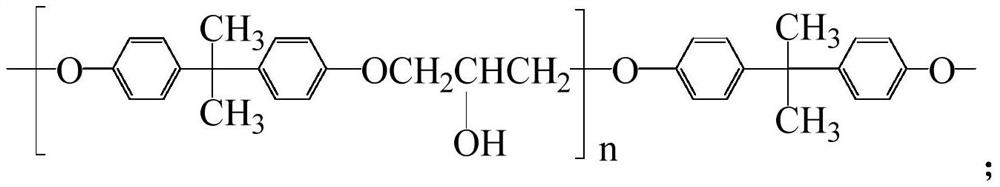

[0042] A thioxanthone polyurethane modified epoxy acrylate LED photocurable resin A:

[0043] a) Preparation of epoxy acrylate E44A: Add 136.3 parts of bisphenol A epoxy resin E-44 into a four-necked flask equipped with a reflux condenser, thermometer, dropping funnel and stirrer, and wait until the temperature rises to 80°C Slowly add dropwise a mixture of 43.2 parts of acrylic acid, 4.5 parts of N,N-dimethylaniline and 0.5 part of p-hydroxyanisole, after the addition is complete, slowly raise the temperature to 85-90°C, keep the temperature for 3 hours, and then take samples every 40 minutes Detect the acid value of the system, stop the reaction when the detected acid value is lower than 5mgKOH / g, and prepare epoxy acrylate E44A;

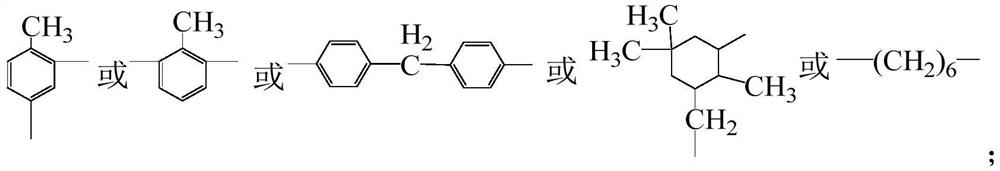

[0044] b), preparation of isocyanate-acrylic acid functional monomer TDI-HEMA: add 52.0 parts of TDI-80 and 0.03 part of DBTDL in a four-necked flask equipped with a reflux condenser, a thermometer, a dropping funnel and a stirrer, stir and heat u...

Embodiment 2

[0050] A thioxanthone polyurethane modified epoxy acrylate LED photocurable resin B:

[0051] a) Preparation of epoxy acrylate E51A: Add 78.4 parts of bisphenol A epoxy resin E-51 into a four-necked flask equipped with a reflux condenser, thermometer, dropping funnel and stirrer, and wait until the temperature rises to 80°C Slowly add dropwise a mixture of 34.4 parts of methacrylic acid, 2.8 parts of catalyst (the mass ratio of N,N-dimethylaniline to tetrabutylammonium bromide is 1:1) and 0.34 parts of p-hydroxyanisole, dropwise After completion, slowly raise the temperature to 85-90°C, keep it warm for 3 hours, then take samples every 30 minutes to detect the acid value of the system, stop the reaction when the detected acid value is lower than 5mgKOH / g, and prepare epoxy acrylate E51A;

[0052] b) Preparation of isocyanate-acrylic acid functional monomer IPDI-HEA: Add 44.5 parts of IPDI and 0.03 parts of DBTDL into a four-neck flask equipped with a reflux condenser, thermome...

Embodiment 3

[0058] A thioxanthone polyurethane modified epoxy acrylate LED photocurable resin C:

[0059] a) Preparation of epoxy acrylate E51A: Add 78.4 parts of bisphenol A epoxy resin E-51 into a four-necked flask equipped with a reflux condenser, thermometer, dropping funnel and stirrer, and wait until the temperature rises to 80°C Slowly add dropwise a mixture of 34.4 parts of methacrylic acid, 2.8 parts of catalyst (the mass ratio of N,N-dimethylaniline to tetrabutylammonium bromide is 1:1) and 0.34 parts of p-hydroxyanisole, dropwise After completion, slowly raise the temperature to 85-90°C, keep it warm for 3 hours, then take samples every 30 minutes to detect the acid value of the system, stop the reaction when the detected acid value is lower than 5mgKOH / g, and prepare epoxy acrylate E51A;

[0060] b) Preparation of isocyanate-acrylic acid functional monomer HDI-HEA: Add 33.6 parts of HDI and 0.02 parts of DBTDL into a four-necked flask equipped with a reflux condenser, a thermo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com