High-transparency microcrystalline glass containing scintillation nanocrystals and preparation method thereof

A glass-ceramic and nano-crystal technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of cumbersome preparation process, complicated process, not many, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Highly transparent glass-ceramics containing scintillation nanocrystals and a preparation method thereof, comprising the following steps:

[0035] 1) Preparation of raw materials: Weigh the required glass raw materials in proportion, put the weighed raw materials in a mortar and grind them thoroughly, so that the raw materials are mixed evenly.

[0036] 2) High-temperature melting: transfer the glass mixed raw material obtained in step 1) to a crucible, and then place the crucible containing the raw material in a high-temperature furnace for firing. The cover plate covers the crucible.

[0037] 3) Casting: pouring the molten glass fired in step 2) onto the preheated mold, and cooling the molten glass rapidly to obtain glass.

[0038] 4) Annealing: Put the glass prepared in step 3) into a furnace at a temperature of 400-500° C. for 180-240 minutes for annealing treatment to eliminate thermal stress in the glass, and then cool to room temperature with the furnace to obtain...

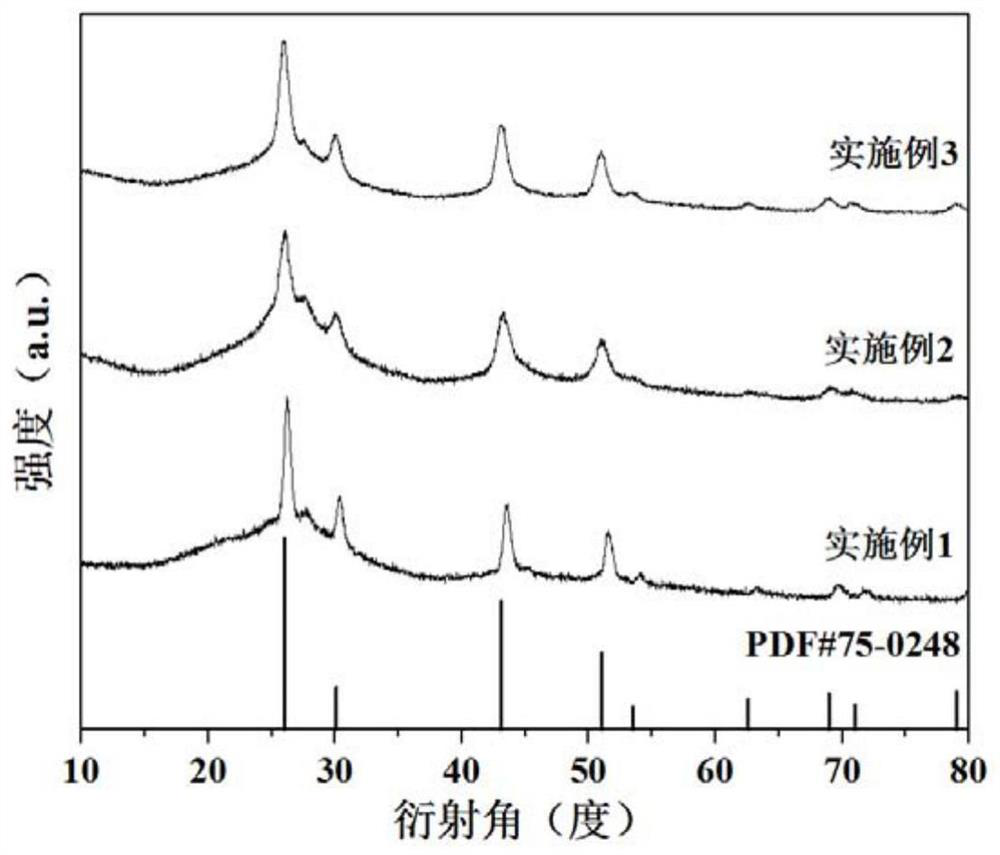

Embodiment 1

[0045] Preparation of highly transparent glass-ceramics containing scintillation nanocrystals, the specific steps are as follows:

[0046] (1) Equipped with raw materials: choose SiO 2 , KF, LaF 3 , GdF 3 , CeF 3 As a raw material, the molar ratio between each raw material is SiO 2 :KF:LaF 3 :GdF 3 : CeF 3 =70:15:5:10:0.5 Ratio Accurately weigh a total of 30g of glass raw materials, put the weighed mixed raw materials into a mortar and grind them thoroughly for 15 minutes to obtain a uniformly mixed glass mixture.

[0047] (2) High-temperature melting: transfer the mixed glass raw materials to a quartz crucible, and then put the crucible containing the raw materials into a high-temperature furnace at 1570°C for 20 minutes. The cover plate covers the crucible.

[0048] (3) Casting molding: pour the molten glass stock solution on a copper plate preheated at 100°C, press another copper plate at the same temperature to form a 2mm sheet, and rapidly cool the glass stock sol...

Embodiment 2

[0053] Preparation of highly transparent glass-ceramics containing scintillation nanocrystals, the specific steps are as follows:

[0054] (1) Equipped with raw materials: choose SiO 2 , KF, LaF 3 , CeF 3 As a raw material, the molar ratio between each raw material is SiO 2 :KF:LaF 3 : CeF 3 =80:10:10:0.6 Ratio Accurately weigh a total of 30g of glass raw materials, put the weighed mixed raw materials into a mortar and fully grind for 15 minutes to obtain a uniformly mixed glass mixture.

[0055] (2) High-temperature melting: transfer the mixed glass raw materials to a quartz crucible, and then put the crucible containing the raw materials into a high-temperature furnace at 1600 ° C for 30 minutes. The cover plate covers the crucible.

[0056] (3) Casting molding: pour the molten glass stock solution on a copper plate preheated at 200°C, press another copper plate at the same temperature to form a 2mm sheet, and rapidly cool the glass stock solution to obtain glass.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com