Self-calibration and compensation method for framework nonorthogonal angle of triaxial rotating inertial navigation syste

An inertial navigation system, three-axis rotation technology, applied in the direction of measuring devices, instruments, etc., can solve the research on non-orthogonal angle calibration of the rotating inertial navigation frame is rare, reduce the attitude output accuracy of the rotating inertial navigation system, and the attitude output of the rotating inertial navigation system Accuracy drop and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention will be further described below in conjunction with the accompanying drawings.

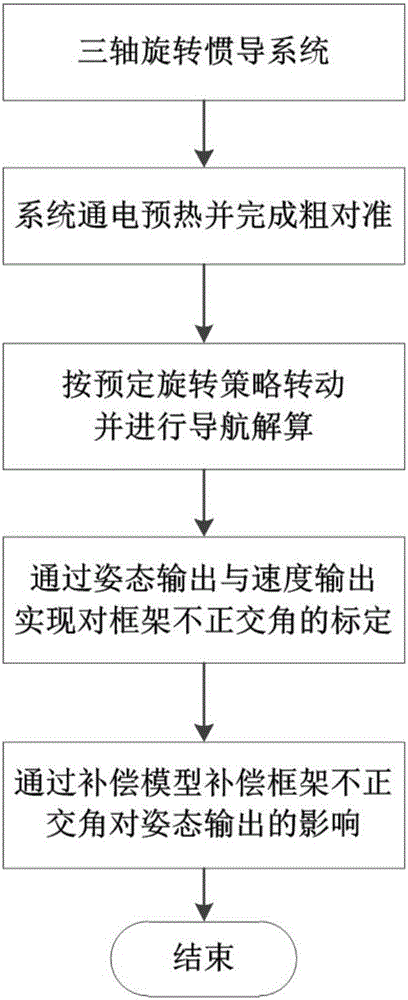

[0080] figure 1 The flow chart of the implementation of the non-orthogonal angle self-calibration and compensation method for the frame of the three-axis rotary inertial navigation system of the present invention is given. The main steps of the method are: the three-axis rotary inertial navigation system is powered on for preheating and rough alignment is completed; the three-axis rotary inertial navigation system controls the rotation of the frame according to a predetermined selection strategy and performs navigation calculation at the same time; records the attitude output during the navigation process With the speed output, the calibration of the non-orthogonal angle of the three-axis rotary inertial navigation system frame is realized through the recursive least square algorithm; the influence of the non-orthogonal angle of the frame on the attitude output of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com