Brake-tire-ground inner rotary drum type inertia brake test bench

A brake test and brake technology, which is applied in the testing of machine/structural components, vehicle testing, instruments, etc., can solve the problems of not being able to reflect the braking process of the car, so as to improve the safety of the test, increase the stability and safety , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A specific embodiment will be described in detail below in conjunction with the accompanying drawings.

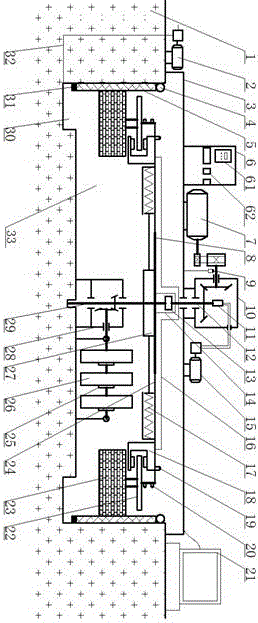

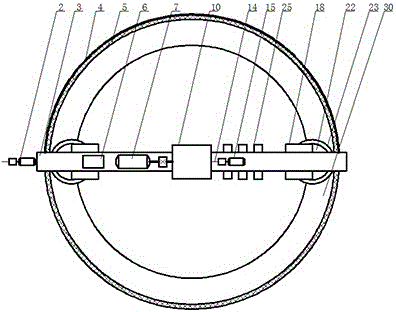

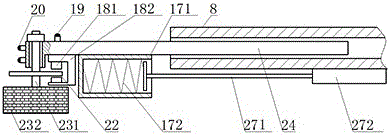

[0030] Please refer to figure 1 , figure 2 and image 3, the present invention provides an inner drum type inertia braking test bench including brake-tire-ground, including foundation 1, drainage pump 2, bracket 3, water spray pipe 4, ground material structure 5, control cabinet 6, frequency conversion 61, PLC62, frequency conversion motor 7, rotating arm 8, vehicle speed sensor 9, upper reducer 10, rotary joint 11, upper rotating shaft 12, coupling 13, telescopic oil pipe 14, hydraulic station 15, brake oil pipe 16, two Spring structure 17, two brakes 18, two braking force sensors 19, two wheel speed sensors 20, industrial computer 21, two brake discs 22, two symmetrically arranged wheels 23, telescopic half shaft 24, electromagnetic clutch 25 , inertial flywheel 26, hydraulic cylinder 27, lower reducer 28, lower rotating shaft 29, sump 30, positioning clip 31, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com