A micro-nano preparation method of a high-precision microlens array structure

A micro-lens array, high-precision technology, used in lenses, instruments, optics, etc., can solve the problems of large processing size, long processing cycle, tool wear, etc., and achieve the effect of high processing precision, low processing cost, and efficient processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings.

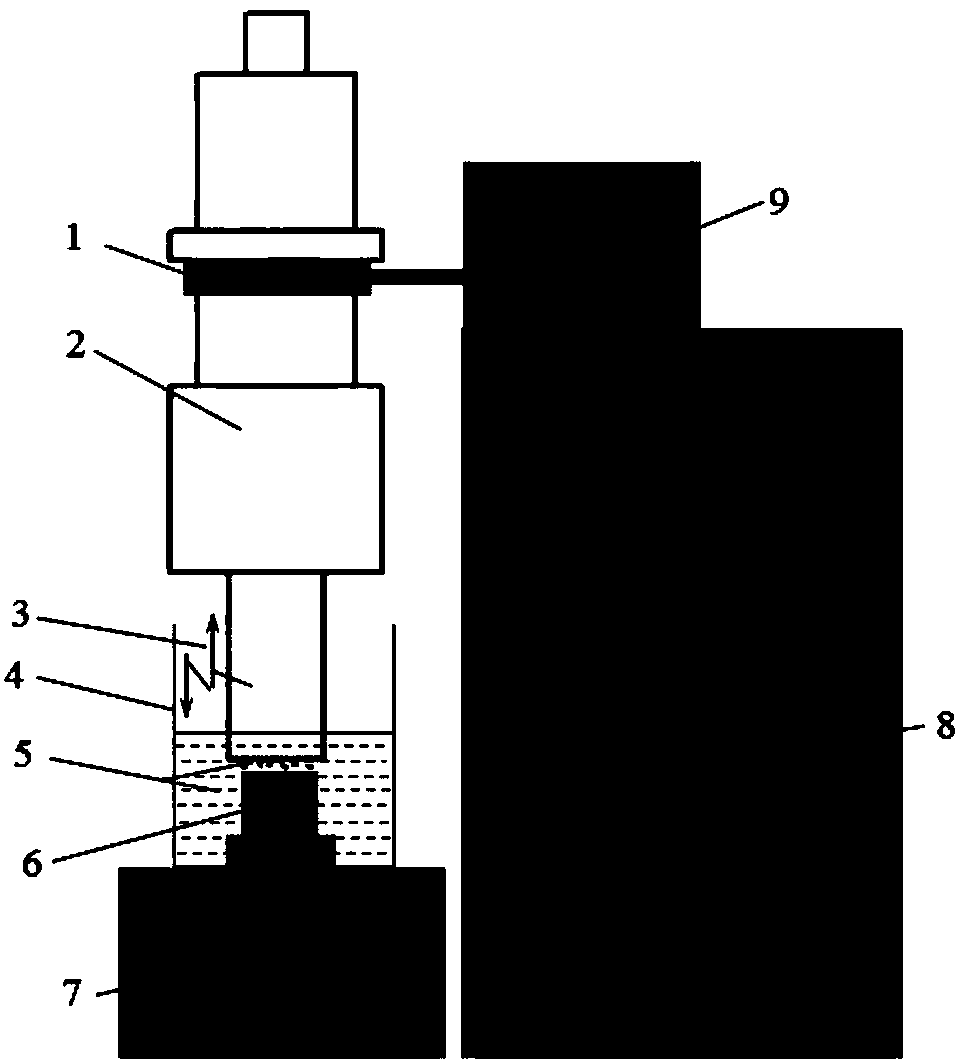

[0030] figure 1 It is a diagram of the ultrasonic vibration polishing process device involved in the present invention, wherein the transducer 2 is clamped by the fixed bracket 1, and the fixed bracket 1 is tightened and fixed by the clamp 9, and the clamp 9 is fixed on the surface of the supporting device 8, and the transducer 2 The lower end vibrates along the longitudinal direction 3 at ultrasonic frequency, and drives the diamond suspension 5 in the container 4 to vibrate rapidly, and the particles in the diamond suspension 5 impact the upper surface of the cemented carbide mold 6 at a very fast speed to polish the cemented carbide The upper surface of the mold 6 has a microlens array structure processed by a femtosecond laser, and the hard metal mold 6 is supported by a supporting structure 7 .

[0031] A micro-nano prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com