Centralized control system for intelligent heat pump cleaning machine

A centralized control system, intelligent heat pump technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as the inability to meet the heat demand for production, the inability of the heat pump system to obtain real-time, and the impact of cleaning product quality, etc. The effect of reducing inventory difficulty, increasing energy utilization, and facilitating management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principles and features of the present invention will be described in detail below in conjunction with the examples, which are only used to describe the present invention and are not intended to limit the scope of the present invention.

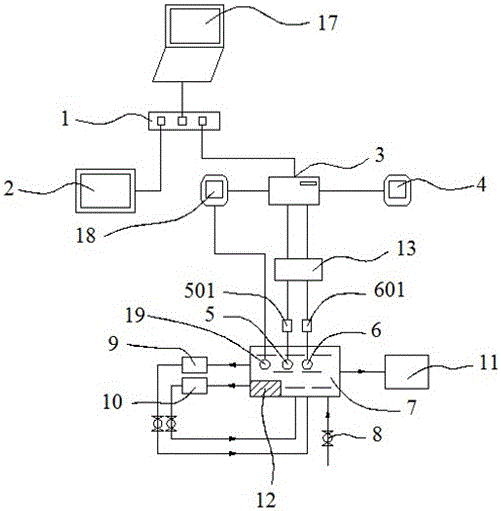

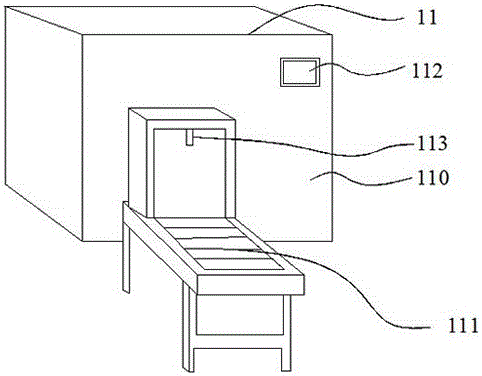

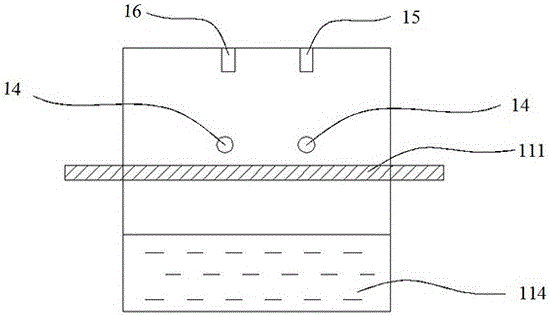

[0030] A centralized control system for an intelligent heat pump cleaning machine. The automatic control system includes a switch 1, a touch screen 2 connected to the switch, and a PLC module 3. The switch is also connected to a host computer 17 through a network cable. The host computer can monitor the heat pump and the The running state of the cleaning machine can be timely and effectively managed for information interaction and centralized control between the two systems; the PLC module 3 is connected to the smart meter 4 through the RS485 serial port to obtain the real-time power consumption, cumulative power consumption, and distribution of the system. segment electricity consumption, etc., and transmit the data to the touch sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com