Control method based on plc in centralized control system of heat pump and washing machine

A centralized control system and control method technology, applied in the field of automatic control, can solve problems such as low degree of automation, failure to meet process requirements, and waste of energy, so as to prevent waste of water sources, improve work efficiency, and accurately detect water temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The principles and features of the present invention will be described in detail below in conjunction with the examples, which are only used to describe the present invention and are not intended to limit the scope of the present invention.

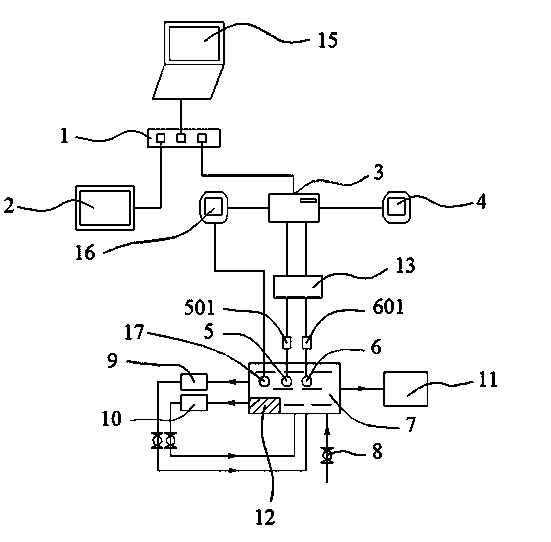

[0049] Based on the PLC control method in the heat pump and cleaning machine centralized control system, the centralized control system includes a heat pump system, an automatic control system and a cleaning machine 11; the heat pump system includes two groups of heat pump units, a pool 7, and a supplementary water pump 8; The two groups of heat pump units are the first group of heat pump units 9 and the second group of heat pump units 10. Those skilled in the art can choose how many groups of heat pump units and the number of heat pump units of each group according to the specific working conditions when implementing the present invention. The number of heat pumps; the automatic control system includes a switch 1 and a touch screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com