Aluminum foil coating process of high-frequency and high-speed cable and corresponding production structure of aluminum foil coating process

An aluminum foil-coated, high-frequency technology, used in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of pitch, uneven outer surface, uneven coating, etc., to ensure uniformity, outer surface Smooth and universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

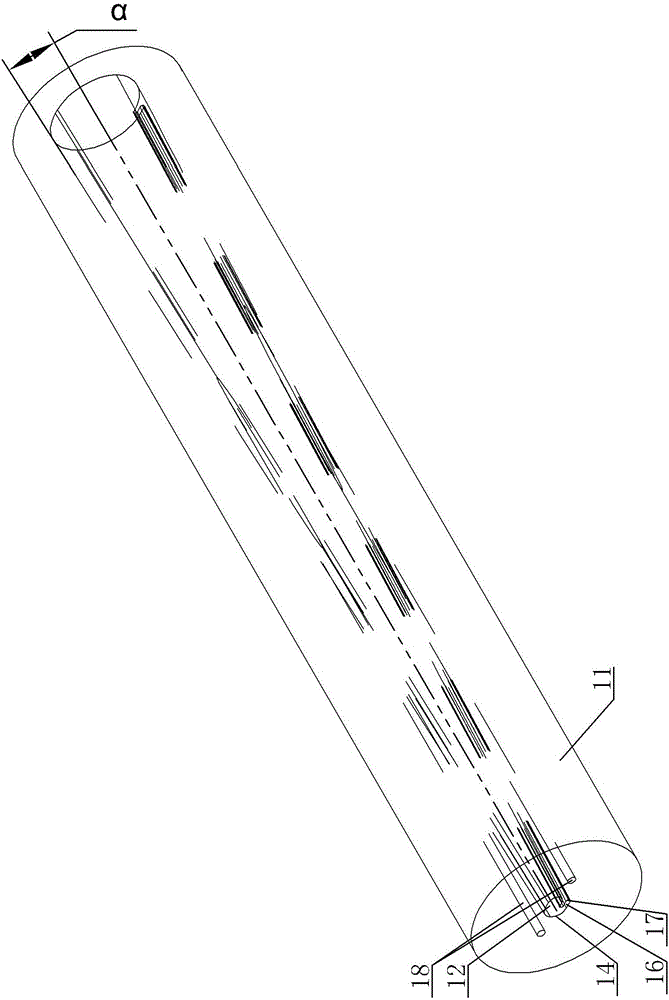

[0027] Aluminum foil covering process for high-frequency and high-speed cables: synchronously input the inner core and aluminum foil into the towing fixture, the inner core runs through the center of the towing fixture, and the aluminum foil is gradually wrapped on the inner core along the inner wall of the towing fixture The outer surface.

[0028] The towing jig is fixed, the inner core and aluminum foil enter the towing jig at the same speed, and the width direction of the aluminum foil can cover the outer torus of the inner core;

[0029] The width of the aluminum foil is greater than the perimeter of the outer toroidal surface of the inner core, and one end of the aluminum foil in the width direction is press-fitted on the other end of the aluminum foil in the width direction after wrapping is completed.

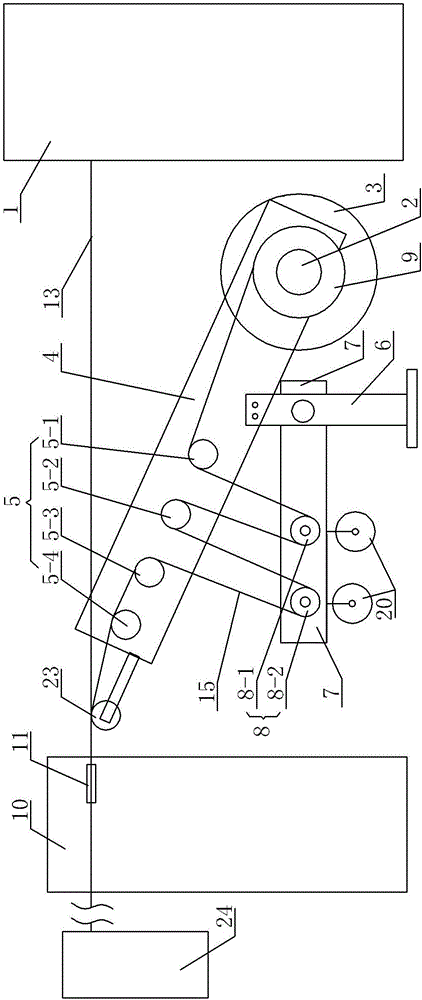

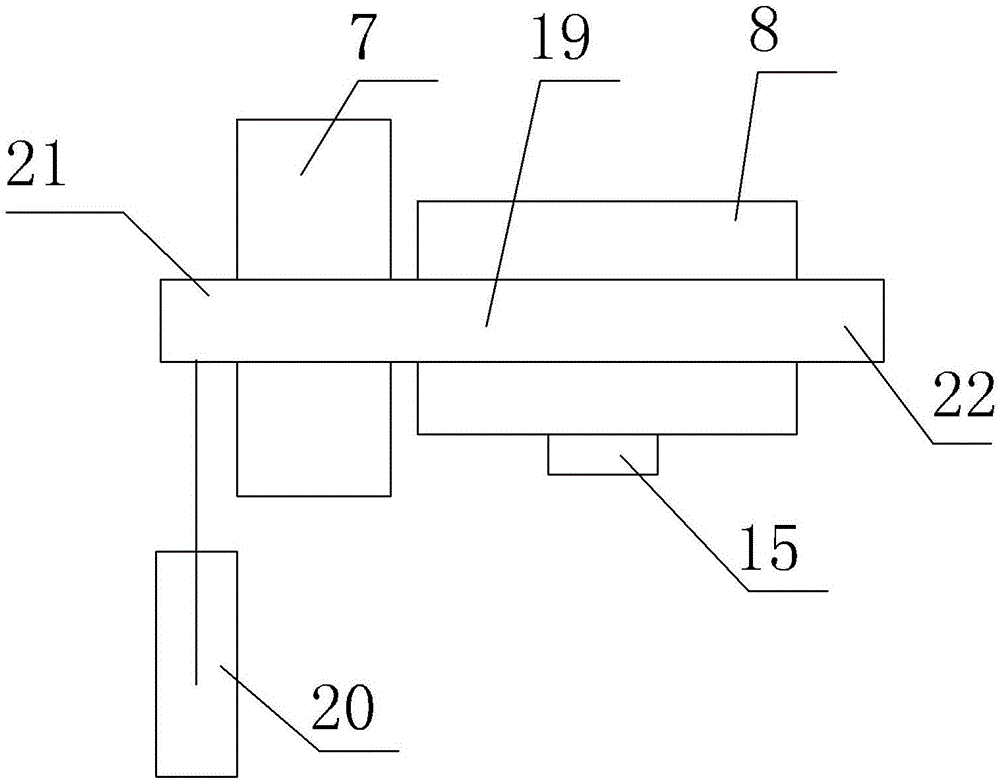

[0030] Aluminum foil cladding production line structure for high-frequency and high-speed cables, see Figure 1 ~ Figure 4 : It includes an inner core conveying frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com