Large transparent flotation column for dynamics research of mineral machining

A technology of dynamics and flotation columns, which is applied in the field of large transparent flotation columns for mineral processing dynamics research, can solve the problems of insufficient tolerance, high cost, and no equipment invention and use, etc., to improve the convenience of use Good resistance, good compressive strength and good light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

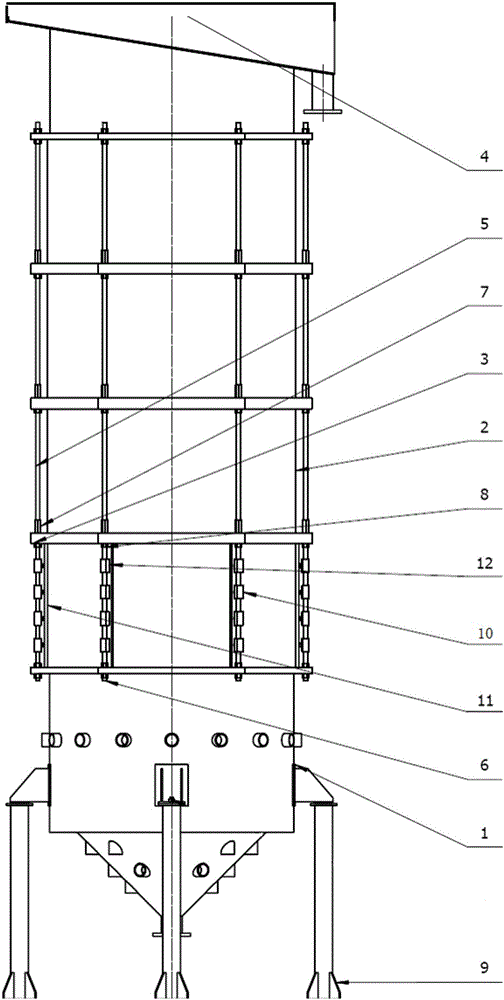

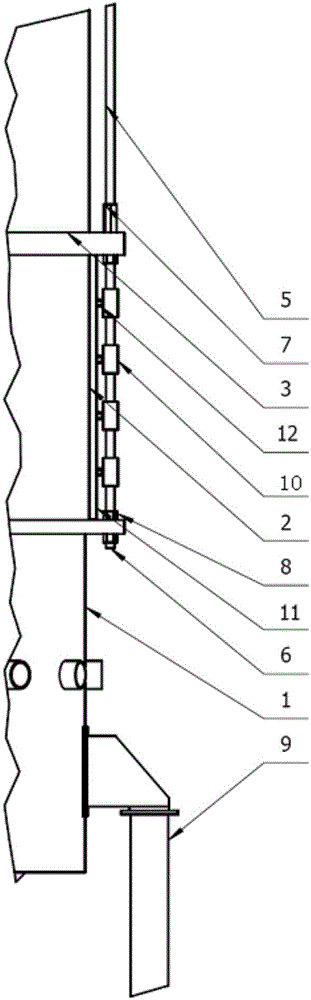

[0028] Embodiment 1: as figure 1 As shown, a large-scale transparent flotation column for mineral processing dynamics research includes several support columns 9, a lower column 1 installed on the support column 9, a bottom cone is installed on the bottom surface of the lower column 1, and the bottom cone There are several foamer interfaces on the body, and a number of supporting devices extending upwards are installed on the upper part of the lower column body 1. The top of the supporting device is connected to the upper column body 4, and the supporting device is tightly attached to the lower column body 1 and the upper column body. Body 4 is connected to the outside of transparent cylinder 2. The support column 9 is placed on the foundation, the lower column 1 is fixed in the middle of the support column 9, a foamer is installed on the bottom cone, the transparent column 2 is placed above the lower column 1, and its top is connected to the upper column 4, When in use, the ...

Embodiment 2

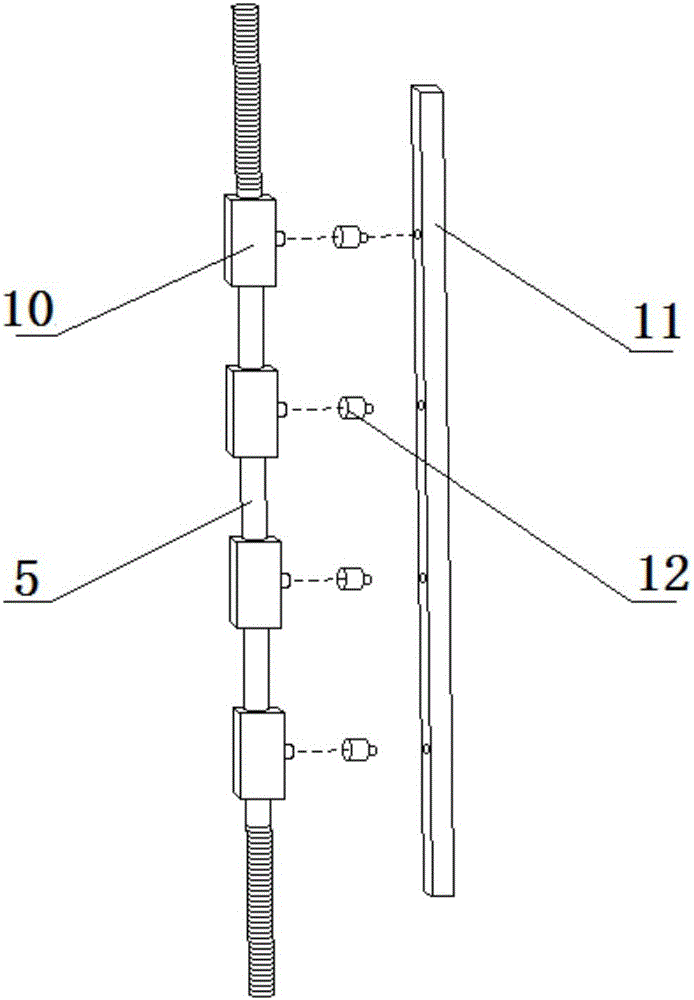

[0031] Embodiment 2: as figure 2 , image 3 As shown, on the basis of Example 1, the transparent glass cylinder is composed of several sections of annular glass longitudinally, the lower end of the lowermost annular glass is connected and installed on the lower column 1, and the uppermost annular glass The upper end of the ring glass is connected and installed on the upper column 4, the upper end of the lowermost annular glass, the lower end of the uppermost annular glass and the upper and lower ends of each remaining section of annular glass are butt-connected and installed on the connecting ring 3 rings . The upper and lower sides of the connecting ring 3 rings are provided with placement grooves corresponding to the thickness of the annular glass, which are used to place and fix the annular glass. Due to the large size of the flotation column, it is too difficult to design a whole transparent glass body And the bearing capacity is reduced. Therefore, the use of multi-seg...

Embodiment 3

[0034] Embodiment 3: as Figure 4 As shown, on the basis of Embodiment 1, the structure of the supporting device is changed, and only a few connecting screws 5 are tightly fixed to the outer wall of the transparent cylinder 2 for support. The ring glass is made of laminated glass. The ring glass is made of laminated glass. Good compressive strength, good light transmission, easy to observe the operation of gas, solid and liquid three phases inside the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com