Water-cooling wall pipe replacing process

A water-cooled wall and process technology, applied in the field of pipe changing process, can solve the problems of high working intensity, poor working environment, high risk, etc., and achieve the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

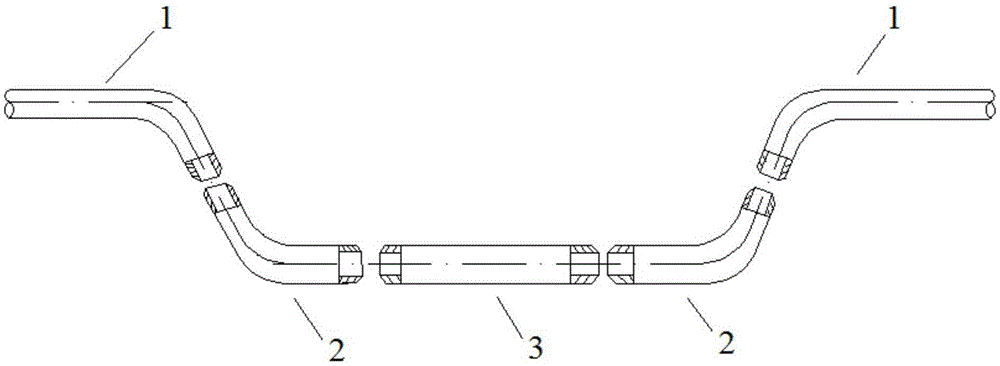

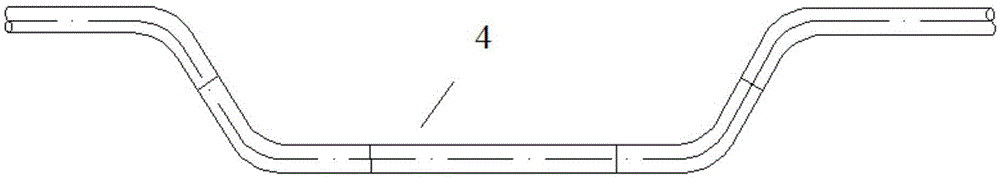

[0029] A water-cooled wall pipe replacement process, the schematic diagram of the decomposition structure of the welded pipe is as follows figure 1 As shown, the tube replacement process uses the following steps:

[0030] (1) The boiler is shut down, and the furnace is stuffy until the manhole door can be opened, check the leaking pipes in the water cooling wall, and cut out the gap at the corresponding position of the water cooling wall;

[0031] (2) To cut the leaking part of the pipeline, it is necessary to detect the metallographic structure of the pipe part, and the cutting length is until the metallographic structure of the pipe part is intact;

[0032] (3) Cut off the fins at both ends of the remaining unleaked old elbow 1, use the hot bending method to bend the two ends of the pipe and pull it out from the gap of the gas cutting on the boiler. The fins at both ends of the leaked pipe are baked with a drying gun, and pulled out of the furnace with a chain hoist. After ...

Embodiment 2

[0035] A water-cooled wall pipe replacement process adopts the following steps:

[0036] After the boiler is shut down, the furnace is so stuffy that the manhole door can be opened, and a person uses a strong flashlight outside the manhole door to check the water wall. If there is a trace of water at the leak, the location of the leak can be determined. Since the furnace has been stuffy for more than 30 hours at this time, the boiler pressure is not very high. Use gas to cut a small slit on the sheet, and at the same time use a strong flashlight at the manhole door to observe the leak point in the furnace and the position of the gas cutting Mars, guide the gas cutter to cut a small slit on the fin and approach the leak point, and finally find the exact leak point and leak pipe. Since the small slit of the fins at the leak point is cut, water can be seen spraying out of the leak point outside the furnace, so it will be easy and intuitive to determine the leak point and the leak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com