3D printing device and technique for forming large products

A technology for 3D printing and large-scale products, which is applied in the direction of manufacturing auxiliary devices, additive processing of mixtures of solid materials and liquid materials, processing and manufacturing, etc. Problems such as printing material size and power are small, so as to achieve the effects of less restrictions on printing materials, avoiding thermal collapse, and fast forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

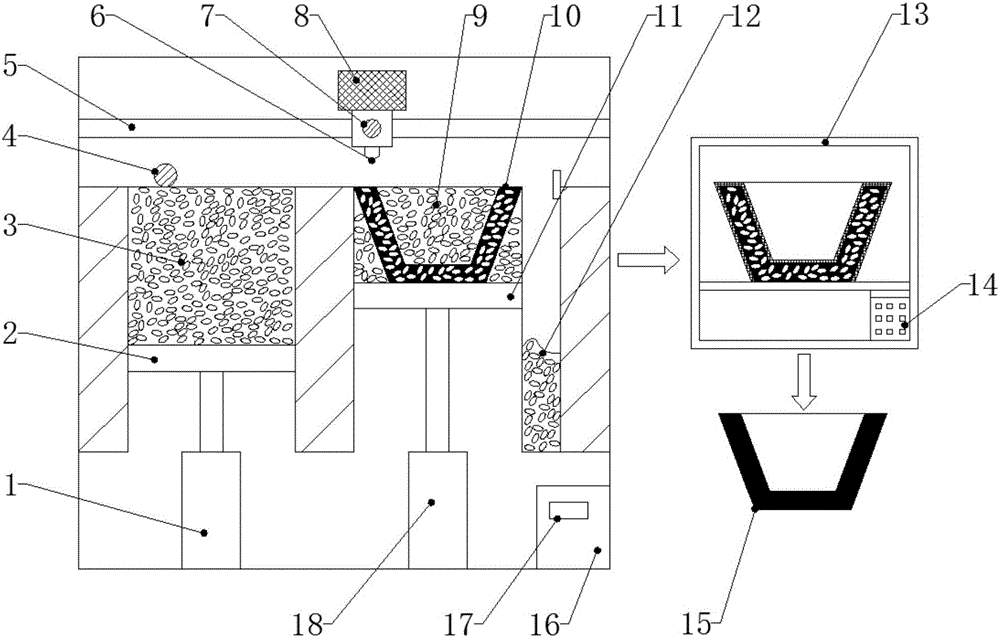

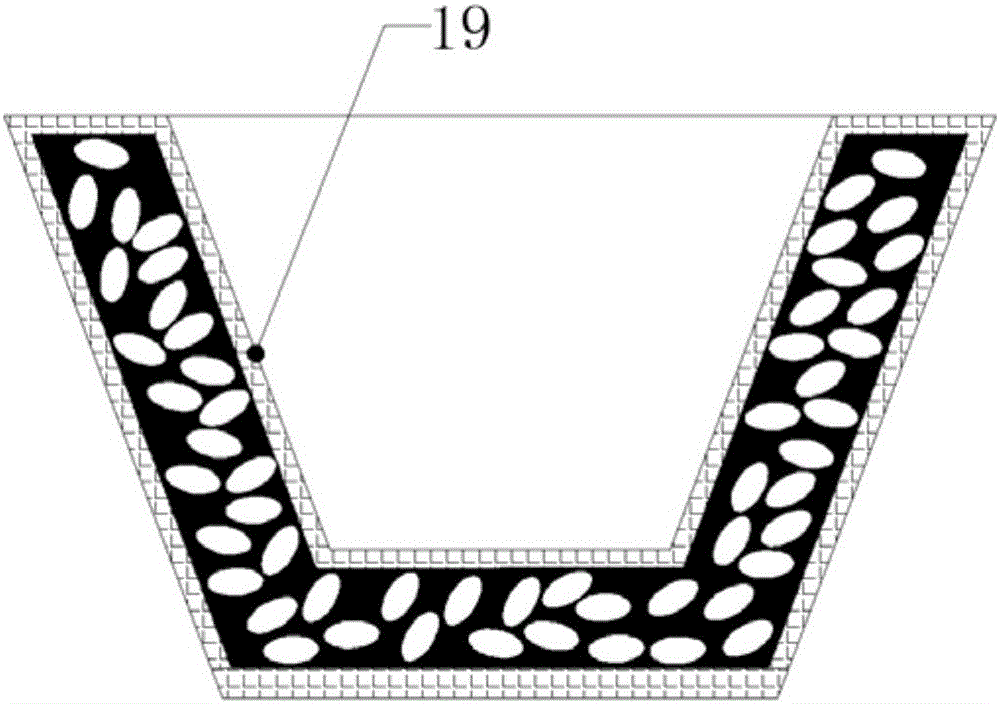

[0022] The present invention proposes a 3D printing device and process for forming large-scale products, such as figure 1As shown, it is mainly composed of injection system, data conversion and control system, three-dimensional motion system, molding system, microwave heating system, etc. The molding system and the microwave heating system are placed separately. The injection system is mainly composed of glue storage box 8 and nozzle 6; the data conversion and control system is mainly composed of motion control card 16 and data storage 17; the three-dimensional motion system is mainly composed of X-direction motion mechanism 5 It is composed of the Y-direction movement mechanism 7, the Z-direction storage chamber movement mechanism 1 and the Z-direction molding chamber movement mechanism 18; the molding system is mainly composed of the storage chamber 3, the storage chamber piston 2, the molding chamber 9, the molding chamber piston 11 and the The material roller 4 is formed; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com