Self-propelled carrying and installing all-in-one ship for underwater tunnel immersed tubes

An underwater tunnel, self-propelled technology, used in the transportation and installation of immersed tubes in cross-sea tunnels or similar components to be installed, in the field of cross-river, can solve the problems of long construction period, low operation efficiency and high construction cost, and achieve high Stable and precise installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

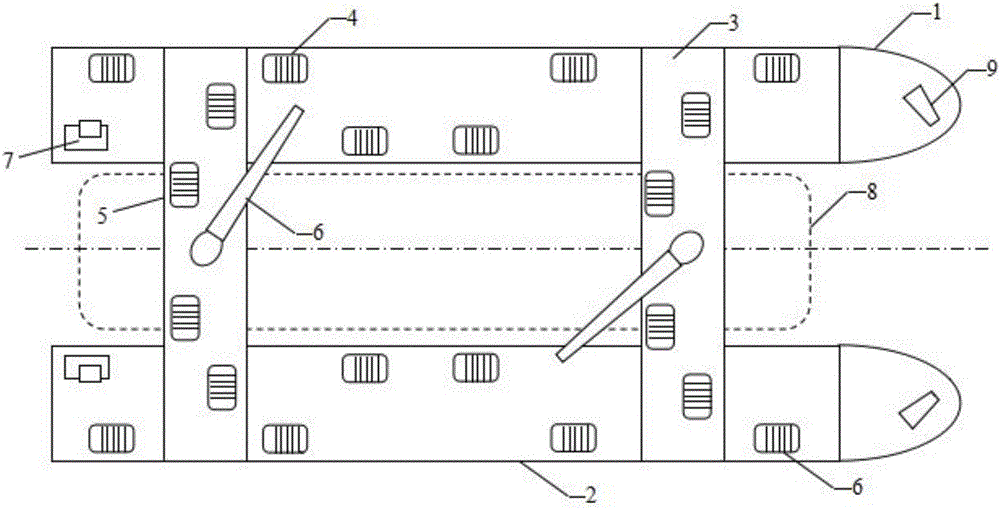

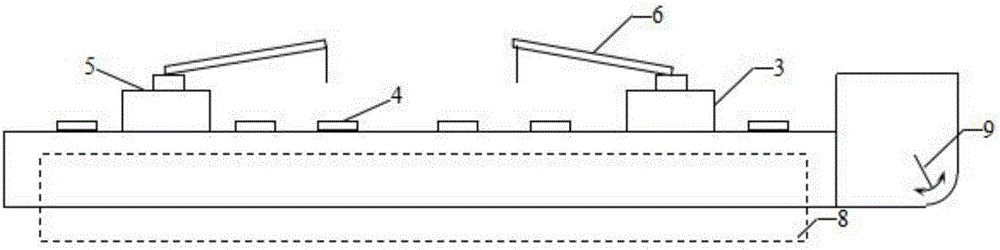

[0018] As shown in the drawings, a self-propelled underwater tunnel immersed tube carrier and installation integrated ship includes a first hull 1, a second hull 2, a first connection structure 3, a second connection structure 5, a winch 4, a crane 6, The propulsion power unit 7 and the positioning device 9, the first hull and the second hull are parallel to each other, a first connecting structure and a second connecting structure are arranged between the first hull and the second hull, two cranes are arranged in total, and the cranes are respectively arranged At the midpoint of the first connection structure and the second connection structure, and the operating radii do not intersect each other, multiple sets of winches are symmetrically arranged on the first hull, the second hull, the first connection structure and the second connection structure, Between the first hull and the second hull below the first connection structure and the second connection structure is a loading...

Embodiment 2

[0020] A self-propelled underwater tunnel immersed tube carrier and installation integrated ship, including a first hull 1, a second hull 2, a first connection structure 3, a second connection structure 5, a winch 4, a crane 6, a propulsion power device 7 and a positioning Device 9, the first hull and the second hull are parallel to each other, a first connecting structure and a second connecting structure are arranged between the first hull and the second hull, four cranes are arranged in total, and two lifting cranes are respectively arranged on the first At the midpoint of the connecting structure and the second connecting structure, the other two cranes are arranged on the first hull and the second hull between the first connecting structure and the second connecting structure, and the working radii of the cranes do not intersect each other, A plurality of sets of winches are arranged symmetrically on the first hull, the second hull, the first connecting structure and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com