Uniform structure type polyisobutylene random copolymer and preparation method thereof

A polyisobutylene-based, random copolymer technology, applied in the field of isobutylene copolymer synthesis, can solve problems such as large difference in reactivity ratio, unstable product performance, and uneven copolymer structure, and achieves reduction of heat generation and prevention of glue The effect of particle bonding and control of polymerization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

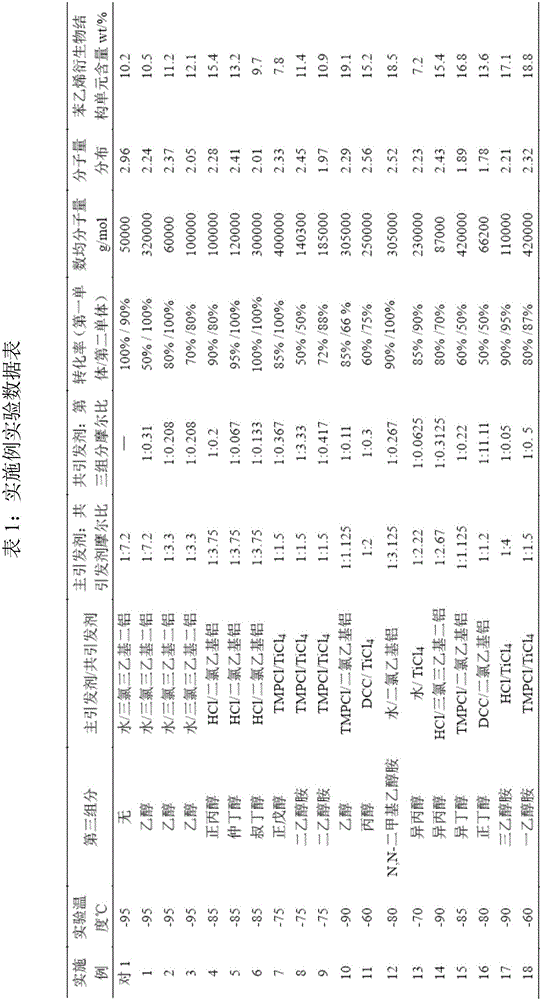

[0029] At -95°C, add 184g of methyl chloride, 40.5g of isobutylene and 26g of p-methylstyrene into the reactor, and mix well. The concentration of isobutylene monomer is 16.2wt%, and the content of p-methylstyrene is 10.4wt%. . Take 1.8ml trichlorotriethyldialuminum chloride solution (0.4M), 1.8mg water and 2.2ml ethanol solution (0.1M) in methyl chloride solution (0.1M), mix and configure it as an initiating system, then add 25ml methyl chloride solution to dilute, in- Low-temperature aging at 95°C for 5 minutes. Squeeze the aged initiator system into the reactor to initiate polymerization, the polymerization time reaches 69 hours sticking to the kettle, add 20ml of pre-cooled methanol to terminate the reaction, and vacuum dry. The number average molecular weight was 320000 g / mol.

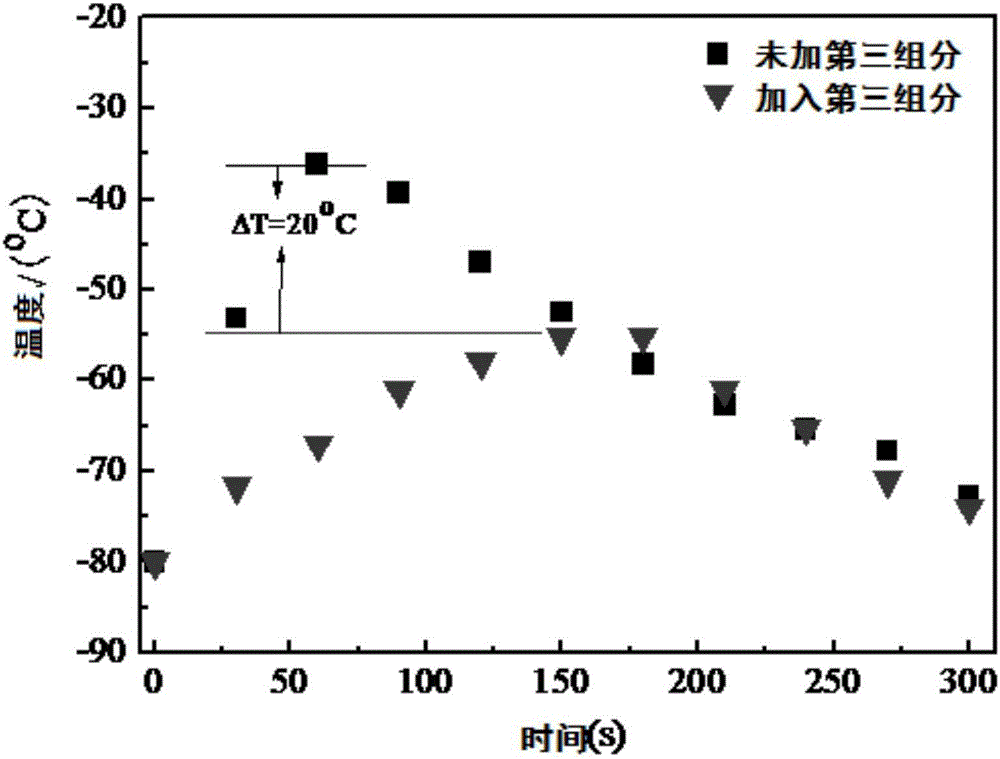

[0030] Such as figure 1 As shown, in the synthesis process of polyisobutylene-based random copolymer, under the same conditions, without adding the third component, the exothermic heat is parti...

Embodiment 2

[0033]At -95°C, add 184g of methyl chloride, 40.5g of isobutylene and 26g of p-tert-butylstyrene to the reactor, then add 1.5ml of ethanol in methyl chloride solution (0.1M), mix well, and the concentration of isobutylene monomer is 12.43wt%, and the content of p-tert-butylstyrene is 13wt%. Take 1.8ml of trichlorotriethyldialuminum chloride solution (0.4M) and 3.89mg of water, mix to configure the initiation system, then add 25ml of methyl chloride to dilute, and age at -95°C for 5min at low temperature. Squeeze the aged initiator system into the reactor to initiate polymerization, the polymerization time reaches 40 hours without sticking to the kettle, add 20ml of pre-cooled methanol to terminate the reaction, and dry in vacuum. The number average molecular weight is 60000 g / mol.

Embodiment 3

[0035] At -95°C, 184g of methyl chloride, 40.5g of isobutylene and 26g of m-methylstyrene were added to the reactor and mixed thoroughly, the concentration of isobutylene monomer was 16.2wt%, and the content of m-methylstyrene was 10.4wt%. Take 1.8ml trichlorotriethyldialuminum chloride solution (0.4M), 3.89mg water and 1.5ml ethanol solution (0.1M) and mix them to form an initiating system, then add 25ml methyl chloride solution for dilution, Under the condition of ℃, low-temperature aging for 5 minutes. Squeeze the aged initiator system into the reactor to initiate polymerization, the polymerization time reaches 40 hours without sticking to the kettle, add 20ml of pre-cooled methanol to terminate the reaction, and dry in vacuum. The number average molecular weight is 100000 g / mol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap