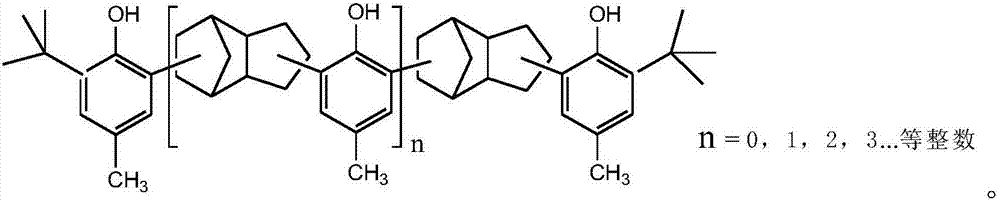

Method used for one-pot synthesis of p-cresol dicyclopentadiene butylation product

A technology of cresol dicyclopentadiene and dicyclopentadiene, which is applied in the field of synthesizing p-cresol dicyclopentadiene butylated products, can solve the difficulty of increasing post-processing purification, strict reaction conditions, and large safety hazards. problems, to achieve the effect of simple operation, stable reaction system and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Add 148g (2mol) tert-butanol, 27g (0.25mol) p-cresol and 0.54g p-toluenesulfonic acid into a 500mL four-necked reaction flask equipped with a stirrer, a thermometer and a condenser, stir well and slowly heat to 80 After ℃, 20.4g (0.15mol) of dicyclopentadiene was slowly added dropwise for 1 hour, and after the dropwise addition was completed, the reaction was kept at 80℃ for 6 hours. Then, 27 g of sulfuric acid with a mass concentration of 80% was slowly added dropwise into the four-necked reaction flask for 1 hour, and after the dropwise addition was completed, the reaction was kept at 80° C. for 4 hours. After the reaction, the reaction solution in the four-necked reaction flask was left to stand for stratification, and the lower aqueous phase was separated, and the upper organic phase was washed to neutrality with a 5% sodium bicarbonate aqueous solution with a mass concentration, and then the washed liquid Stand for stratification, separate the lower aqueous phase, ...

Embodiment 2

[0036] Add 296g (4mol) tert-butanol, 27g (0.25mol) p-cresol and 1.35g p-toluenesulfonic acid into a 500mL four-necked reaction flask equipped with a stirrer, a thermometer and a condenser, stir well and slowly heat to 70 After ℃, 27.2g (0.2mol) of dicyclopentadiene was slowly added dropwise for 1 hour, and after the dropwise addition was completed, the reaction was kept at 70℃ for 4 hours. Then, the temperature of the reaction liquid in the four-necked reaction flask was lowered to 60°C, and then 5.4g of sulfuric acid with a mass concentration of 93% was slowly added dropwise for 0.2h. After the reaction, the reaction solution in the four-necked reaction flask was left to stand for stratification, and the lower aqueous phase was separated, and the upper organic phase was washed to neutrality with a 5% sodium bicarbonate aqueous solution with a mass concentration, and then the washed liquid Stand for stratification, separate the lower aqueous phase, distill the upper organic ph...

Embodiment 3

[0038] Add 132g (2mol) tert-butanol, 27g (0.25mol) p-cresol and 0.81g p-toluenesulfonic acid to a 500mL four-necked reaction flask equipped with a stirrer, a thermometer and a condenser, stir well and slowly heat to 75 After ℃, slowly add 23.1 g (0.175 mol) of dicyclopentadiene dropwise for 1 hour. After the dropwise addition, keep the reaction at 75 ℃ for 5 hours. Then, the temperature of the reaction liquid in the four-necked reaction flask was lowered to 70°C, and then 13.5g of sulfuric acid with a mass concentration of 85% was slowly added dropwise for 0.4h. After the reaction, the reaction solution in the four-necked reaction flask was left to stand for stratification, and the lower aqueous phase was separated, and the upper organic phase was washed to neutrality with a 5% sodium bicarbonate aqueous solution with a mass concentration, and then the washed liquid Stand for stratification, separate the lower aqueous phase, distill the upper organic phase, recover and remove ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap