Method for rapid crystallization of polymer at high temperature

A polymer and rapid technology, applied in the field of polymer materials, can solve the problems of complex process, low temperature, difficult continuous operation, etc., and achieve the effect of easy industrial production, wide application and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

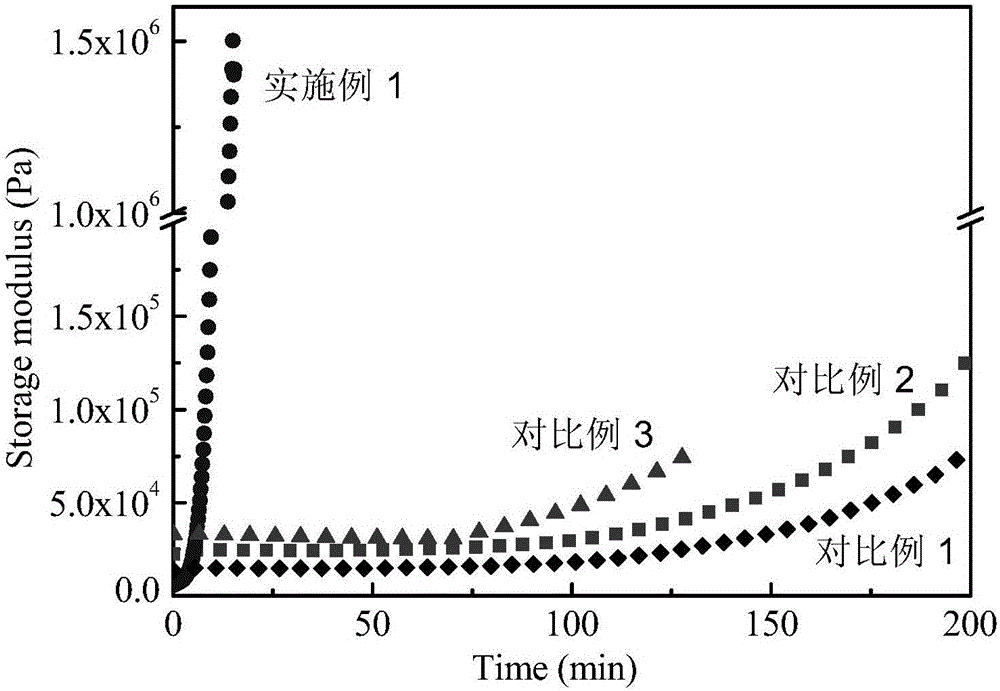

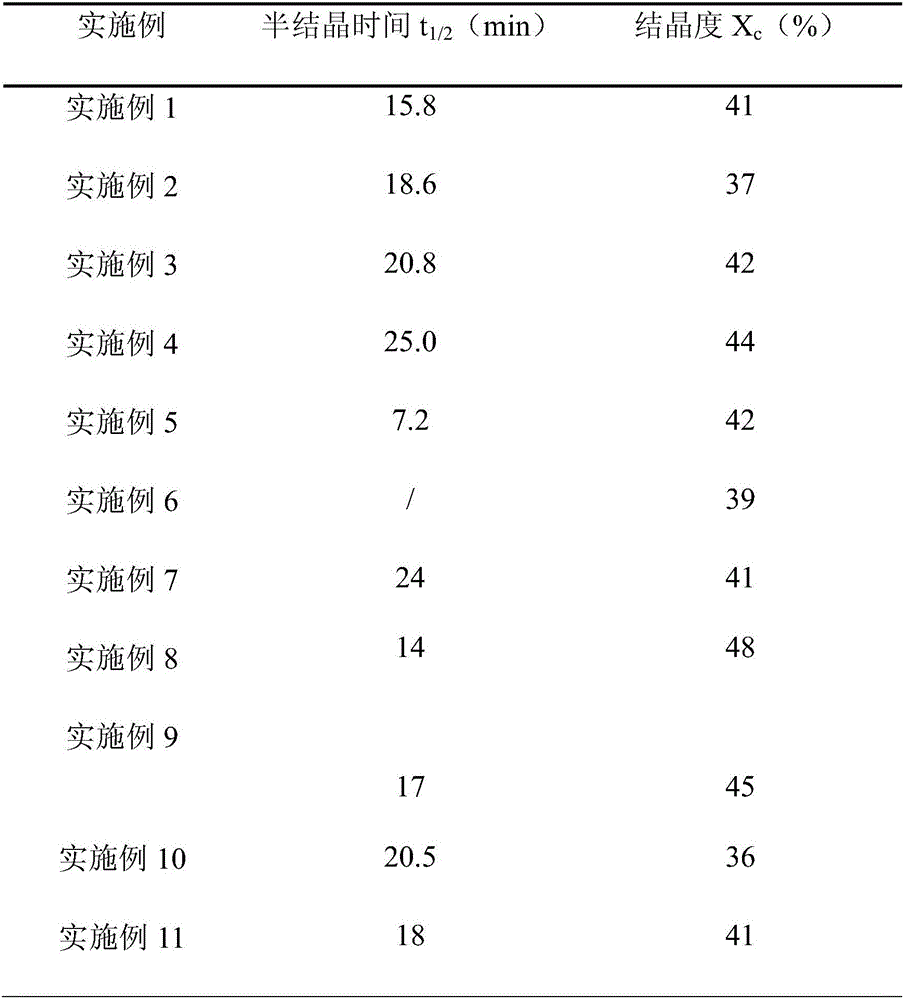

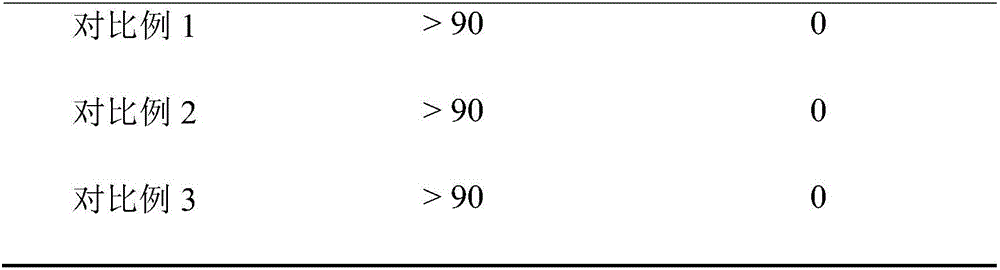

Embodiment 1

[0036] Weigh the dried N,N'-1,2-bis(phenyloxalamide)-ethane and polylactic acid (4032D), add it to the torque rheometer according to the mass ratio of 0.5 / 99.5, and set it at 180°C After melt blending at 50rpm for 4min, the resulting composition was heated to 240°C by a rotational rheometer to completely dissolve N,N'-1,2-bis(phenyloxalamide)-ethane in the poly In lactic acid, keep the temperature constant for 2 minutes, then cool down at 5°C / min to 155°C and apply shear (shear rate: 0.4rad / s, shear time: 5s), then carry out isothermal crystallization test at this temperature, and calculate half Crystallization time (t 1 / 2 ), the sample after the test was characterized by DSC for its crystallinity, and the test results were listed in Table 1.

Embodiment 2

[0038]Weigh the dried N,N'-1,2-bis(phenyloxalamide)-butane and polylactic acid (4032D), add it to the torque rheometer at a mass ratio of 0.5 / 99.5, After melt blending at 50rpm for 4min, the resulting composition was heated up to 200°C in a rotary rheometer, and N,N'-1,2-bis(phenyloxalamide)-butane was completely dissolved in the poly In lactic acid, keep the temperature constant for 2 minutes, then cool down at 5°C / min to 155°C and apply shear (shear rate: 0.4rad / s, shear time: 5s), then carry out isothermal crystallization test at this temperature, and calculate half Crystallization time (t 1 / 2 ), the sample after the test was characterized by DSC for its crystallinity, and the test results were listed in Table 1.

Embodiment 3

[0040] Weigh the dried N,N'-1,2-bis(phenyloxalamide)-butane and polyhydroxybutyrate-valerate copolymer (PHBV), and add it to the In the moment rheometer, after melt blending at 160°C and 50rpm for 4min, the resulting composition was heated up to 200°C in the rotational rheometer, and N,N'-1,2-bis(phenylethanedi Amide)-butane was completely dissolved in polylactic acid, kept at constant temperature for 2 minutes, and then cooled at 5°C / min to 120°C to apply shear (shear rate 0.5rad / s, shear 20s), and then carried out isothermal crystallization at this temperature Test, calculate half crystallization time (t 1 / 2 ), the sample after the test was characterized by DSC for its crystallinity, and the test results were listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| crystallization time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com