Alga taking system and method of spirulina culture machine

A cultivation machine and spirulina technology, applied in the field of microalgae research and cultivation equipment, can solve the problems affecting the continuous cultivation of spirulina, the fragmentation of algal filaments, and the decrease of the purity of spirulina, so as to prevent microbial and miscellaneous algae pollution and achieve high-quality and purity, the effect of ensuring airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

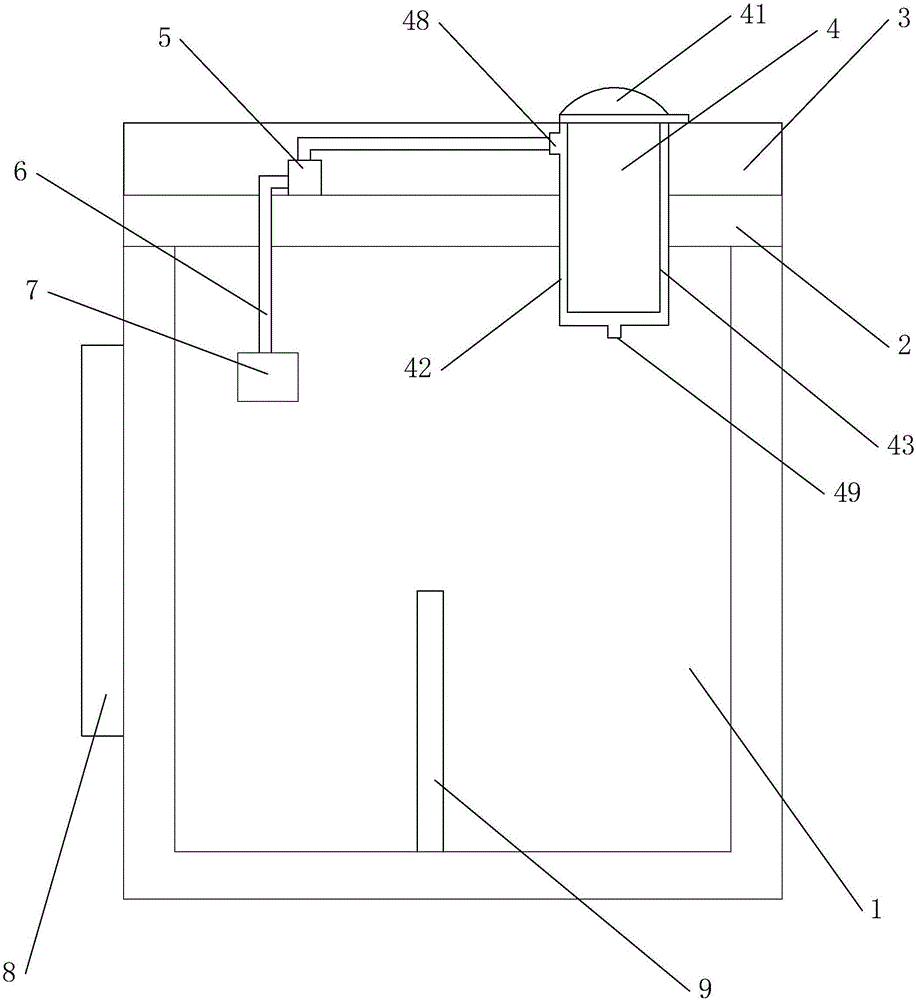

[0030] A household electrical appliance culture and feeding system for spirulina, including a disinfection cabinet, an algae filter cup, a box body 1, a cover body 3, a built-in light transmitting plate 2, an algae taking device 4, a diaphragm pump 5, a filter head 7, and an infusion tube 6. The observation window 8 on the front of the box body 1 and the reference column 9 for taking algae, the box body 1 and the cover 3 are hinged, the built-in plate 2 is arranged inside the box body 1, and the filter head 7 is arranged on the box body Inside 1, the reference column 9 for taking algae is vertically arranged at the bottom of the box 1, and the diaphragm pump 5 is located in the cavity formed by the cover 3 and the built-in light transmitting plate 2;

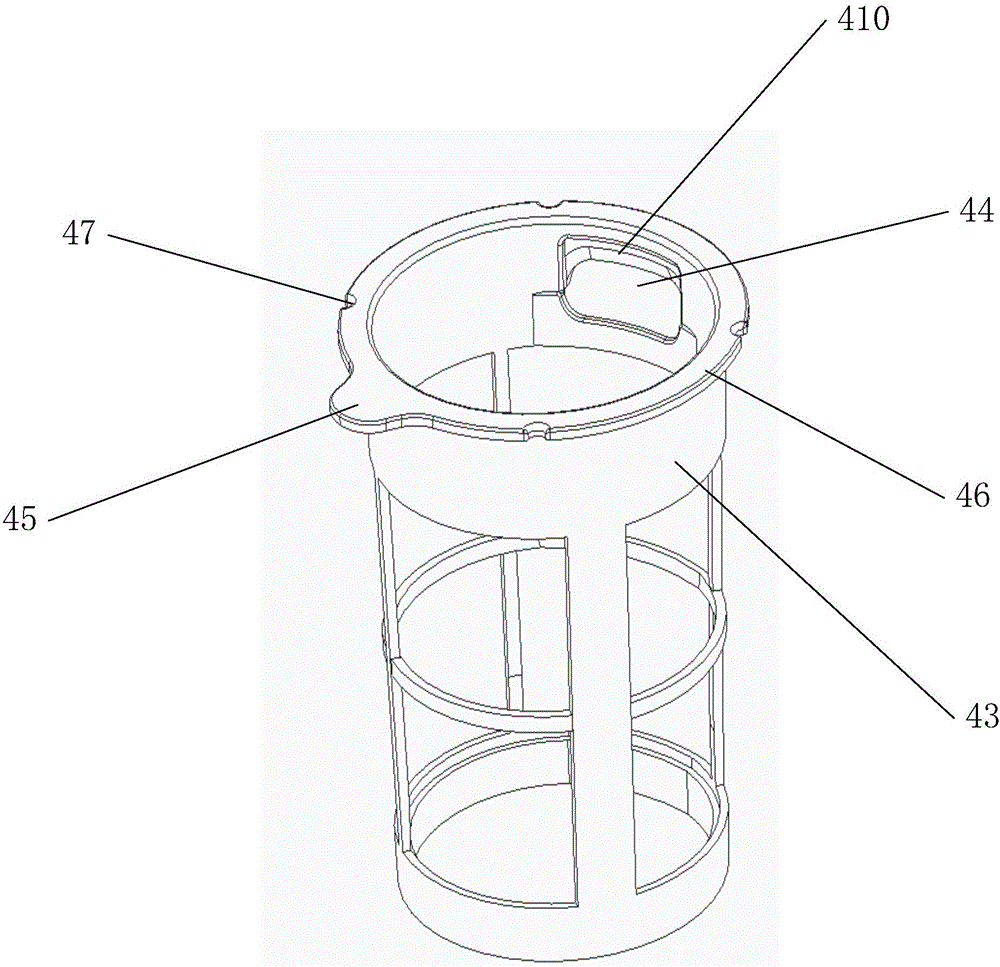

[0031] The algae extracting device 4 includes a top cover 41, a collecting pipe 42, and a cup-type filter screen. The cup-type filter screen is integrally formed and includes a cup body 43 and a filter screen. The filter screen is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com