Efficient pollution-free casting melt homogenous refinement treatment device and method

A processing device and non-polluting technology, which is applied in the field of high-efficiency and non-polluting casting melt homogenization processing devices, can solve the problems of short life, metal pollution, etc., and achieve the effect of increasing the adding speed and solving cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

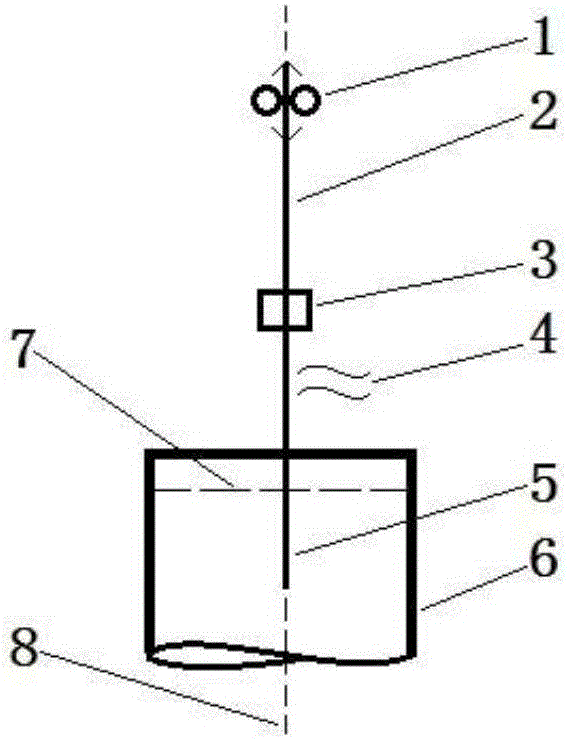

[0030] Adopt this method to carry out homogeneous fine-grained continuous casting of aluminum alloy: firstly, the casting intermediate alloy containing aluminum alloy grain refiner or alloying elements is made into circular cross-section wire rod; Pulled by the wire feeding / unwinding mechanism 1, it passes through the disturbance driving mechanism 3 and heater 4 of the device shown in the figure; when the temperature of the casting melt in the launder and the preheating temperature of the wire reach the set temperature, the wire end The head 5 quantitatively and continuously invades the casting melt at the launder or draft tube. At the same time, under the control of the disturbance drive mechanism 3, the wire end 5 performs continuous disturbance in the melt, causing the wire uniform dissolution. In particular, the end of the wire can also be used as an agitator to control the temperature (melt liquidus temperature ± 50°C), composition (Al-Ti-B: 0.2wt%-2wt%; rare earth elemen...

Embodiment 2

[0032] Adopt this method to carry out continuous preparation of aluminum-based composite material: at first will contain composite material particle (SiC:1wt%-20wt%; Al 2 o 3 : 1wt%-20wt%) or alloy elements (rare earth elements: 0.2wt%-10wt%) cast aluminum-based master alloy (or made by wrapping composite material particles with aluminum foil, filling and compacting in aluminum tubes, etc. Pre-composite material) is made into a wire rod with a circular cross-section; four coils of wire 2 are respectively drawn by an independent wire feeding / unwinding mechanism 1, and pass through the disturbance driving mechanism 3 and the heater 4 of the device as shown in the figure; When the temperature of the casting melt in the launder and the preheating temperature of the wire reach the set temperature, the wire end 5 is quantitatively and continuously intruded into the casting melt at the launder or the draft tube. Under the control of the mechanism 3, the wire end 5 is continuously di...

Embodiment 3

[0034] This method is used for aluminum alloy homogeneous fine-grained rheological die-casting: firstly, the material containing refiner, alloy elements, and composite material additives is prefabricated into a wire rod with a circular cross-section; a roll of wire 2 is used, and the Under the traction of the wire / unwinding mechanism 1, pass through the disturbance drive mechanism 3 and the heater 4 of the device shown in the figure; 5 penetrates into the melt quantitatively, and at the same time, under the control of the disturbance drive mechanism 3, the wire end 5 is continuously disturbed in the melt, resulting in uniform dissolution of the additive wire. In particular, the end of the wire can also be used as a stirrer to homogenize the temperature and composition of the casting melt in the spoon, so that the alloy elements, refiners, and all solutes of the composite material in the melt can be uniformly dispersed; After stirring for a certain period of time or reaching the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com