Thermal Calibration Method of Antirust Aluminum Alloy Sheet Welding Saddle Components

A saddle-shaped, aluminum alloy technology, applied in the field of post-weld deformation correction and thermal correction of thin-walled sheet-welded saddle-shaped components, can solve the problems of large number of welds, difficult assembly, and large dimensional instability of parts. The tooling structure is simple, the loading and unloading is convenient, and the measurement is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0034] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

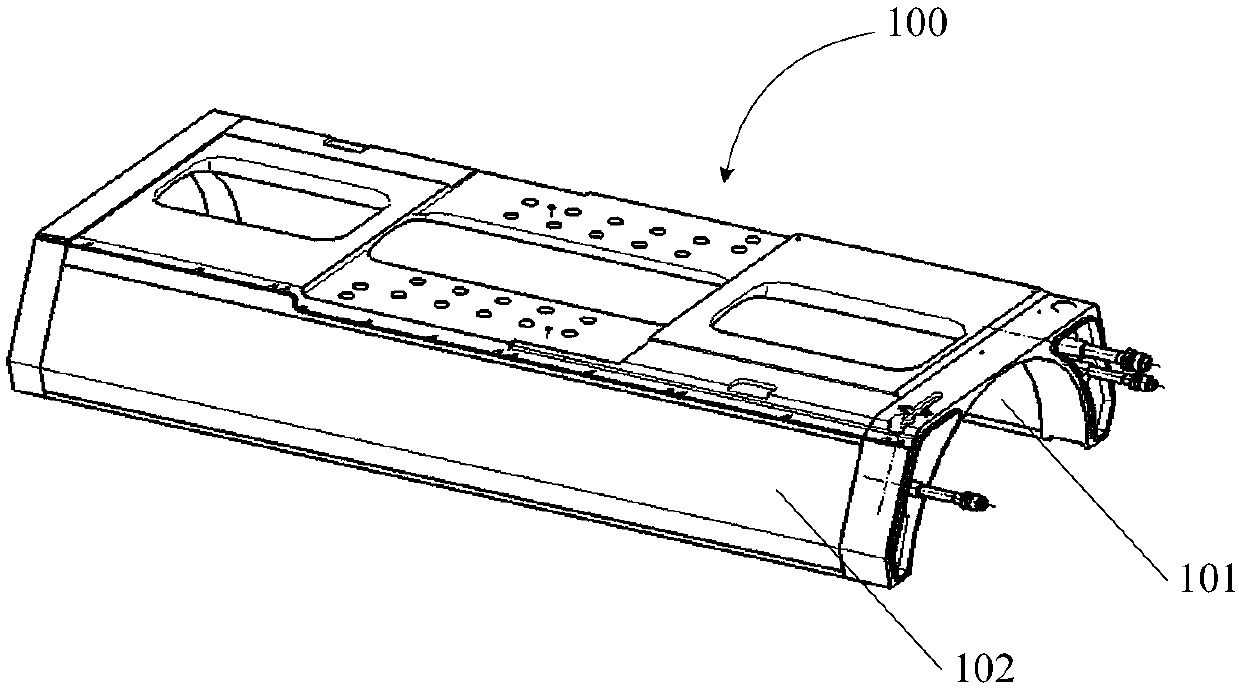

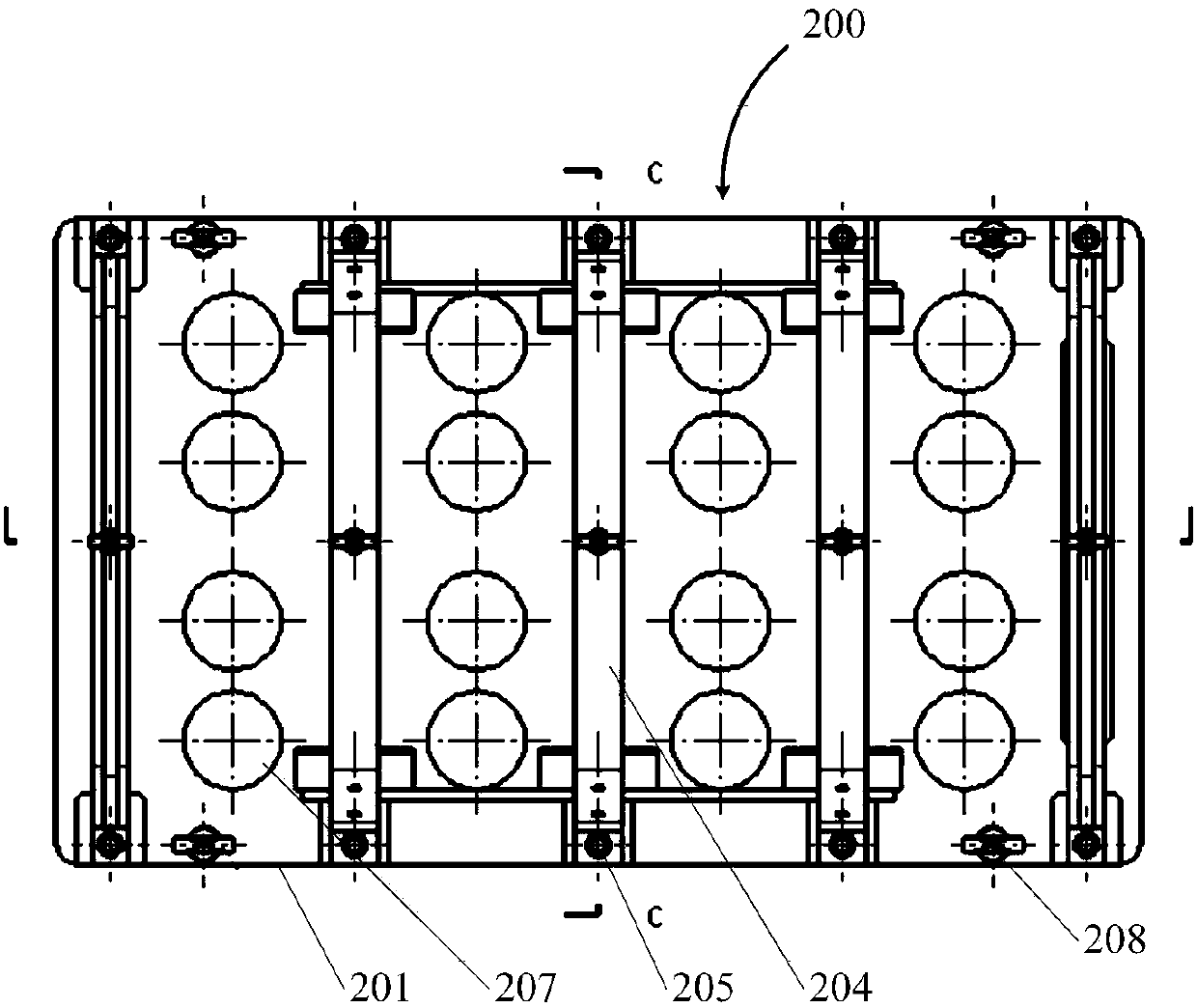

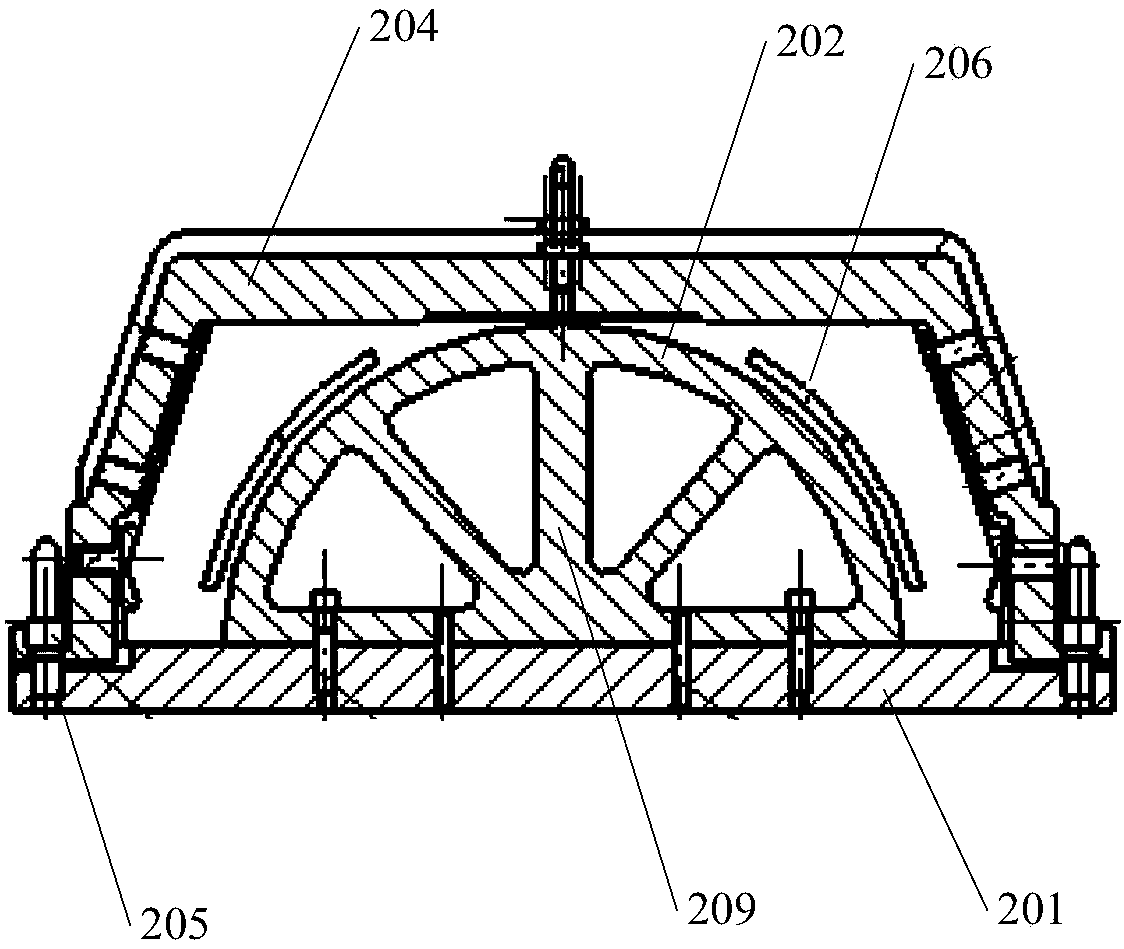

[0035] like figure 1 , figure 2 and Figure 5 As shown, the present invention provides a kind of thermal correction method of antirust aluminum alloy sheet welding saddle member, it is characterized in that, comprises the following steps:

[0036] Step 1. Measure the deflection, inner diameter and maximum outer diameter of the four corners of the component to be corrected relative to its axis, and calculate the corresponding deviation of the component to be corrected relative to the standard component according to the measurement results;

[0037] Wherein, the cross-section o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com