Hollow fiber membrane spinning nozzle and method for preparing hollow fiber membrane

A technology of spinning nozzle and fiber membrane, which is applied in the field of hollow fiber membrane spinning nozzle and preparation of hollow fiber membrane, which can solve the problems of detachment of separation layer and support layer, and achieve the effect of improving production efficiency and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

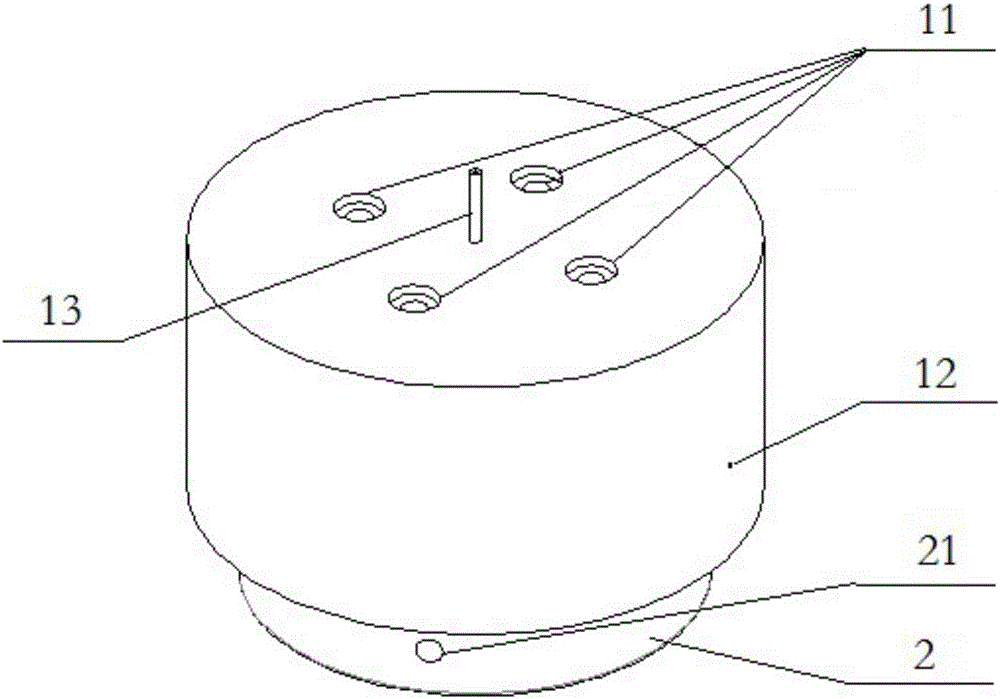

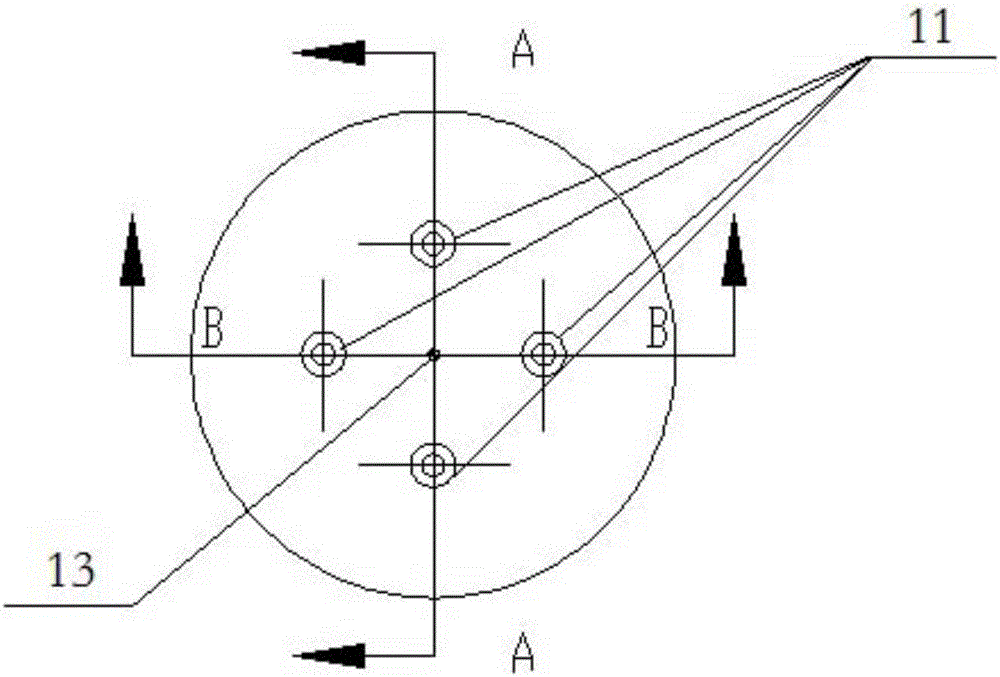

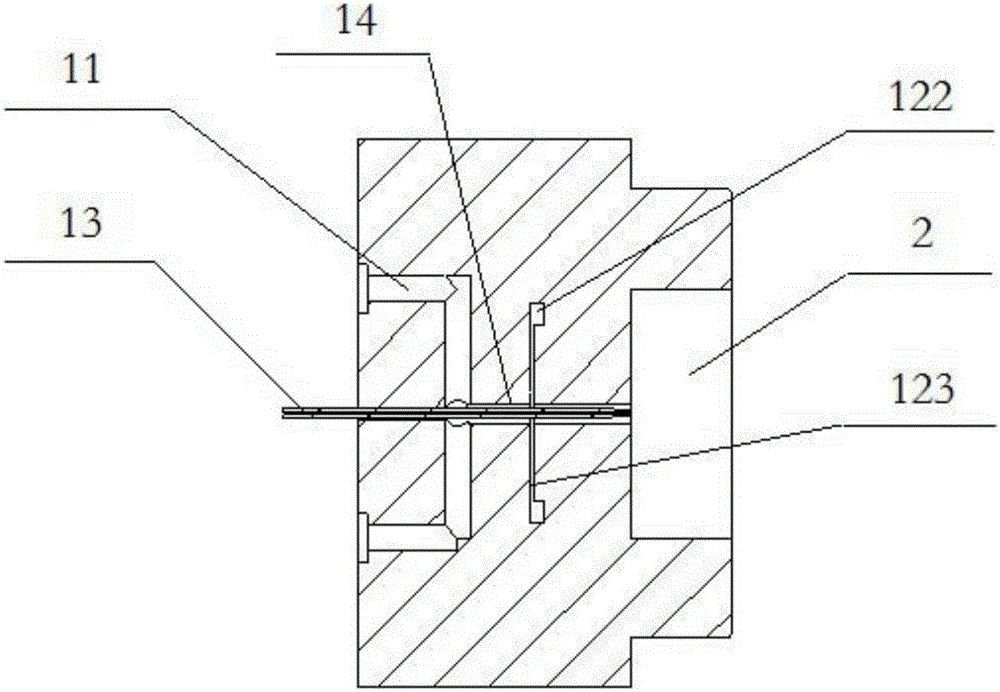

[0033] A hollow fiber membrane spinning nozzle, such as figure 1 As shown, it is a nozzle body with a solution channel, in which channel I11, channel II12, central liquid pipe 13, liquid collection pipe 14 and spinning forming area 2 are set, as shown in FIG. figure 2 , image 3 , Figure 4 and Figure 5 As shown, the channel I11 is "L" type, and there are four channels, the inlets of which are symmetrically distributed on the upper end surface of the nozzle body, and the end communicates with the upper end of the liquid collection pipe 14 arranged in the center of the lower half of the nozzle body; the channel II12 The inlet is set on the side wall of the nozzle body, and the channel II12 is divided into three sections: the first liquid inlet section 121, the solution buffer zone 122 and the second liquid inlet section 123, the first liquid inlet section 121 is a horizontal channel, and the solution buffer zone 122 is a deep groove-shaped annular area with the liquid coll...

Embodiment 2

[0036] Utilize the nozzle of embodiment 1 to carry out the method for hollow fiber membrane preparation, may further comprise the steps:

[0037] Inject the supporting layer spinning solution, separating layer spinning solution and core solution from channel I11, channel II12 and central liquid pipe 13 respectively, the injection speeds are 2mL / min, 0.2mL / min and 1mL / min respectively, and keep the temperature of each solution at 65°C, the spinning solution for the separation layer and the spinning solution for the supporting layer converge at the junction of the liquid collection pipe 14 and the second liquid inlet section 123, and flow to the bottom of the liquid collection pipe 14, where the spray nozzle of the central liquid pipe 13 Contact with the core liquid, perform solvent exchange, and then form a hollow fiber membrane in the spinning forming zone 2 through the nozzle, and pass air at 65°C through the through hole during spinning, and the flow rate is 400mL / min.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Central aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com